Flexible material meets flexibility in design

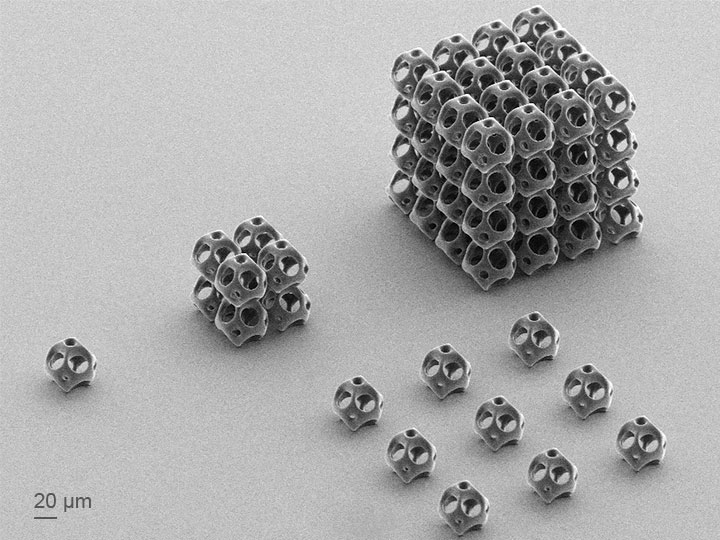

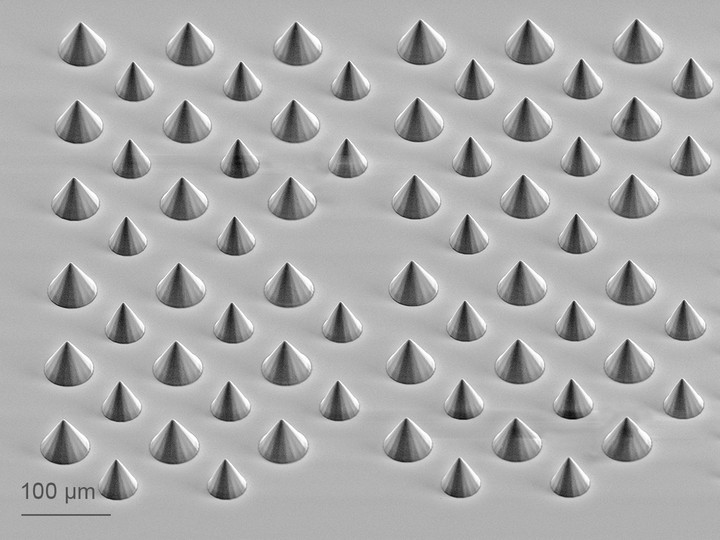

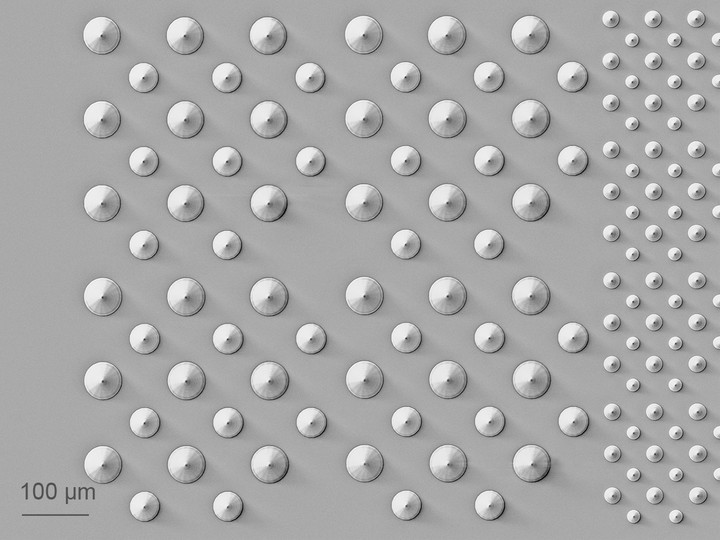

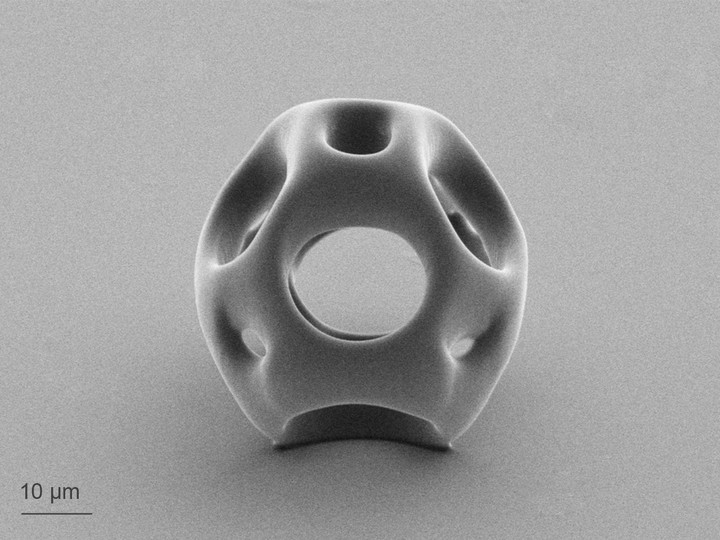

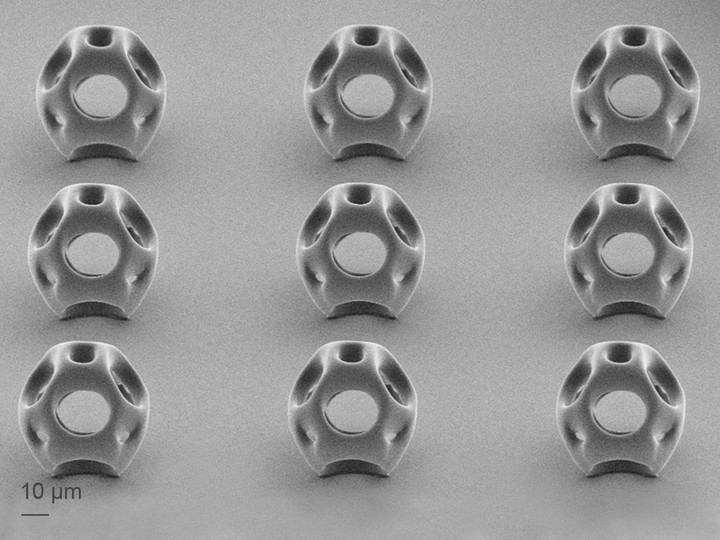

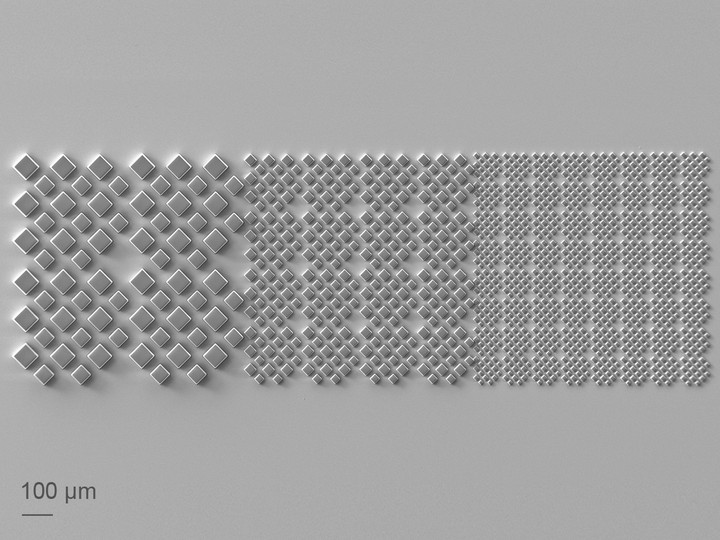

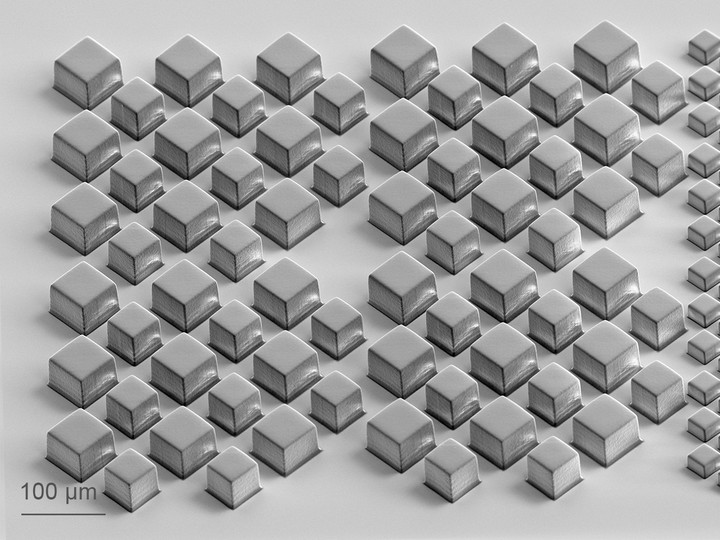

The IP-PDMS photoresin is designed for applications that rely on elastomer-typical material properties: softness, flexibility, elasticity and biocompatibility. These characteristics pave the way for the new photoresin to be used for a wide range of applications, such as 3D-printed cell scaffolds and tissue engineering, 3D-structured surfaces, microfluidic devices or microelectromechanical systems (MEMS). IP-PDMS is optimized for Nanoscribe’s 3D printer and compatible with the 3D Microfabrication Solution Set Medium Features.

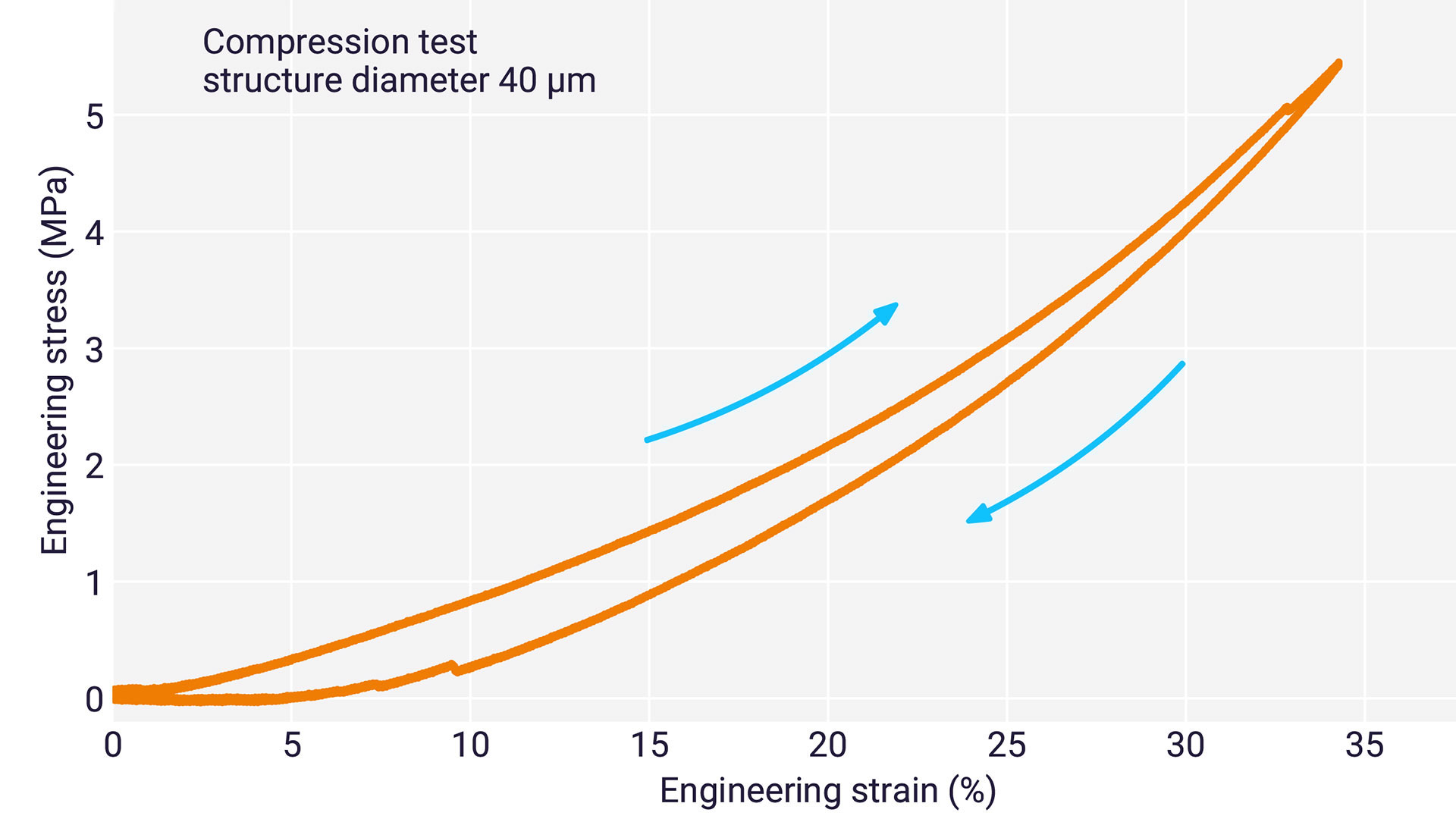

- Highly elastic material with a Young’s modulus about three orders of magnitude lower than IP-S

- Low refractive index photoresin

- Non-cytotoxic according to ISO 10993-5 / USP 87

- Highly flexible material for a wide range of applications