Quantum X shape

High-resolution 3D printing for

best-in-class innovators

Prototyping from nano to meso

The most advanced 3D printer in class. Print any design, features down to 100 nm, areas up to 25 cm²

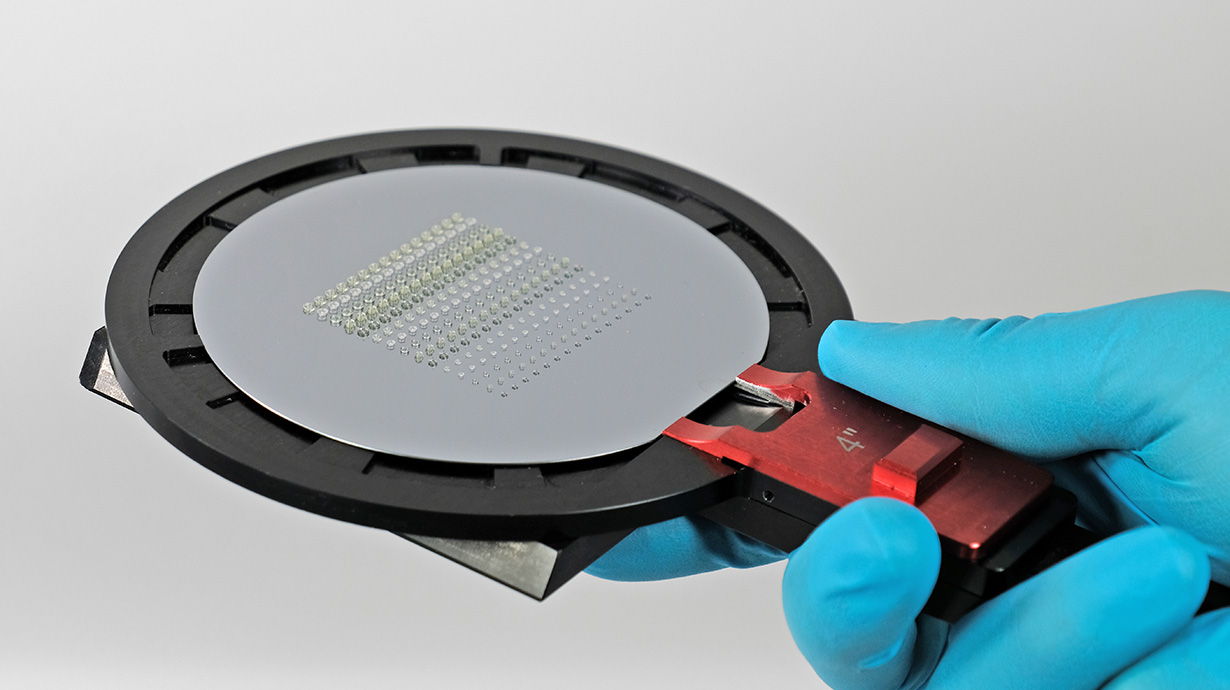

Wafer-scale batch processing

Upright system with automatic dispensing on wafers for more than 200 typical structures overnight

Customizable for various tasks

Choose from a variety of feature options to customize your high-resolution 3D printer

Fastest and most accurate 3D printer

for high-end microfabrication tasks

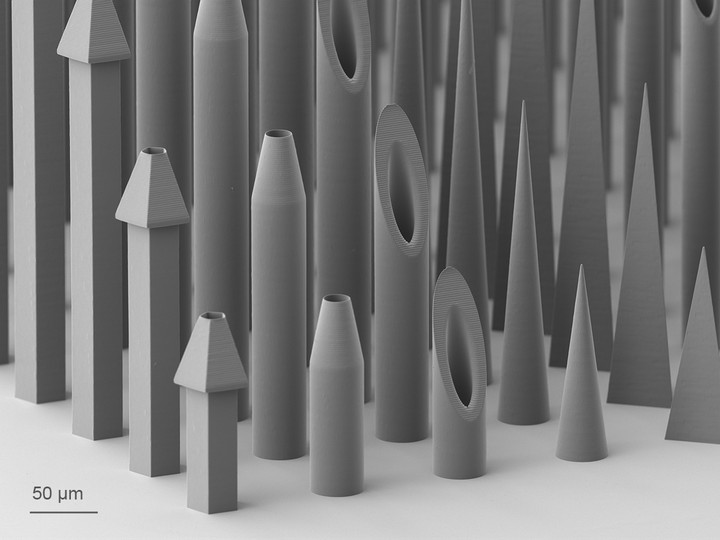

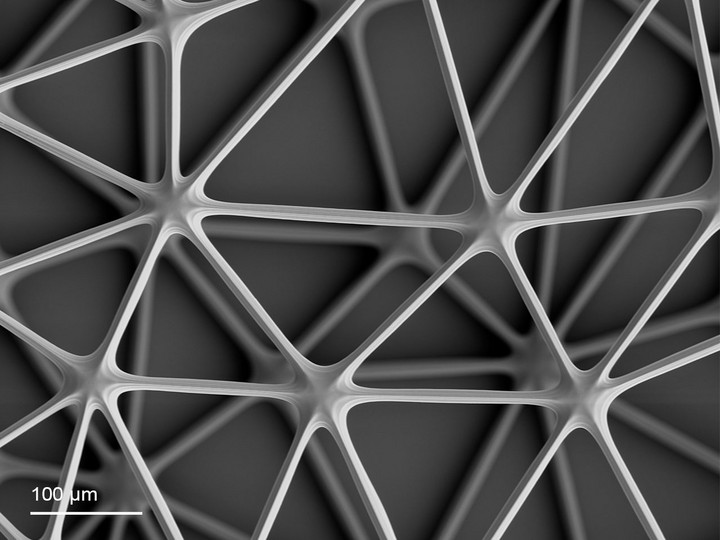

Quantum X shape is a truly capable multi-talent. Based on Two-Photon Polymerization (2PP), the customizable 3D laser lithography system combines proprietary 3D printing technologies that make it the optimal tool for rapid prototyping and wafer-scale batch processing of virtually any 2.5D and 3D shape with submicron precision and accuracy.

Reshaping precision.

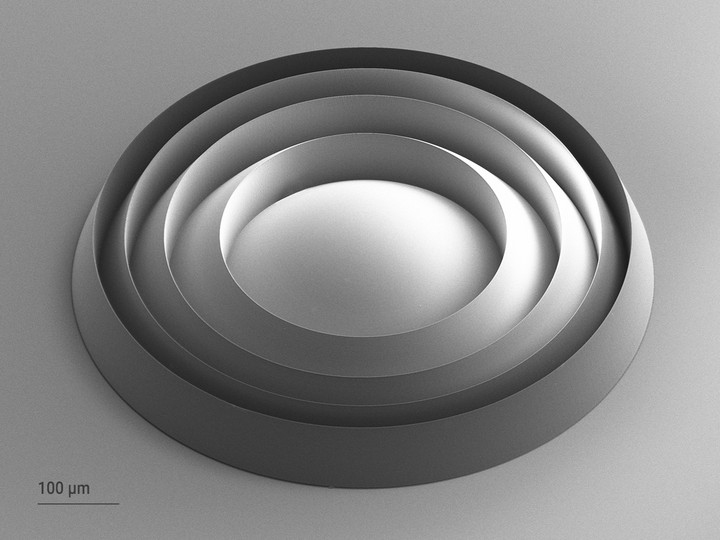

As the second high-resolution two-photon lithography system in the industry-proven Quantum X platform, Quantum X shape offers high-resolution 3D Microfabrication capabilities with unmatched precision, next to Nanoscribe’s breakthrough technology of Two-Photon Grayscale Lithography (2GL ®) for surface patterning. The new Quantum X shape’s superior precision relies on the highest voxel modulation rate in class, and an extremely fine address grid, allowing for sub-voxel size shape control. In addition, you benefit from the 2GL voxel tuning capability for 2.5D structures with stunningly smooth, accurately shaped, or micropatterned surfaces.

Reshaping output.

Quantum X shape is the ideal additive manufacturing tool for rapid prototyping of application designs in biomedical devices, microoptics, microelectromechanical systems (MEMS), microfluidics, surface engineering and many more. Wafer handling capabilities make wafer-scale batch processing and small series production of 3D microparts easier than ever.

Reshaping usability.

Control your print job via the device's integrated touchscreen. Keep an eye on your two-photon lithography system even from the office and in multi-user configurations via nanoConnectX. And benefit from industrial standards and time-efficient wafer batch production.

Technical features in brief

- Rapid prototyping with highest precision and design freedom along a straightforward workflow

- Industry-proven platform for wafer-scale batch processing

- 200 typical mesoscale structures printable overnight

- Print volumes up to 30 cubic centimeters in one pass with the new XLF Print Set

- Broad range of application-specific and universal printing materials

- Open direct laser writing system for custom-made and third-party materials

Printing processes and range of scales

- 2PP-based high-resolution 3D printing

- 2GL Grayscale Lithography for stunningly rapid and accurate surface patterning

- Nanoscale printing – feature size control in x/y direction down to 100 nanometers

- Microscale printing – with typical dimensions from 50 to 700 micrometers

- Mesoscale printing – with dimensions up to several millimeters

- Macroscale printing – XLF Print Set speeds up batch production of voluminous centimeter-sized objects up to 50 x 50 x 12 mm³

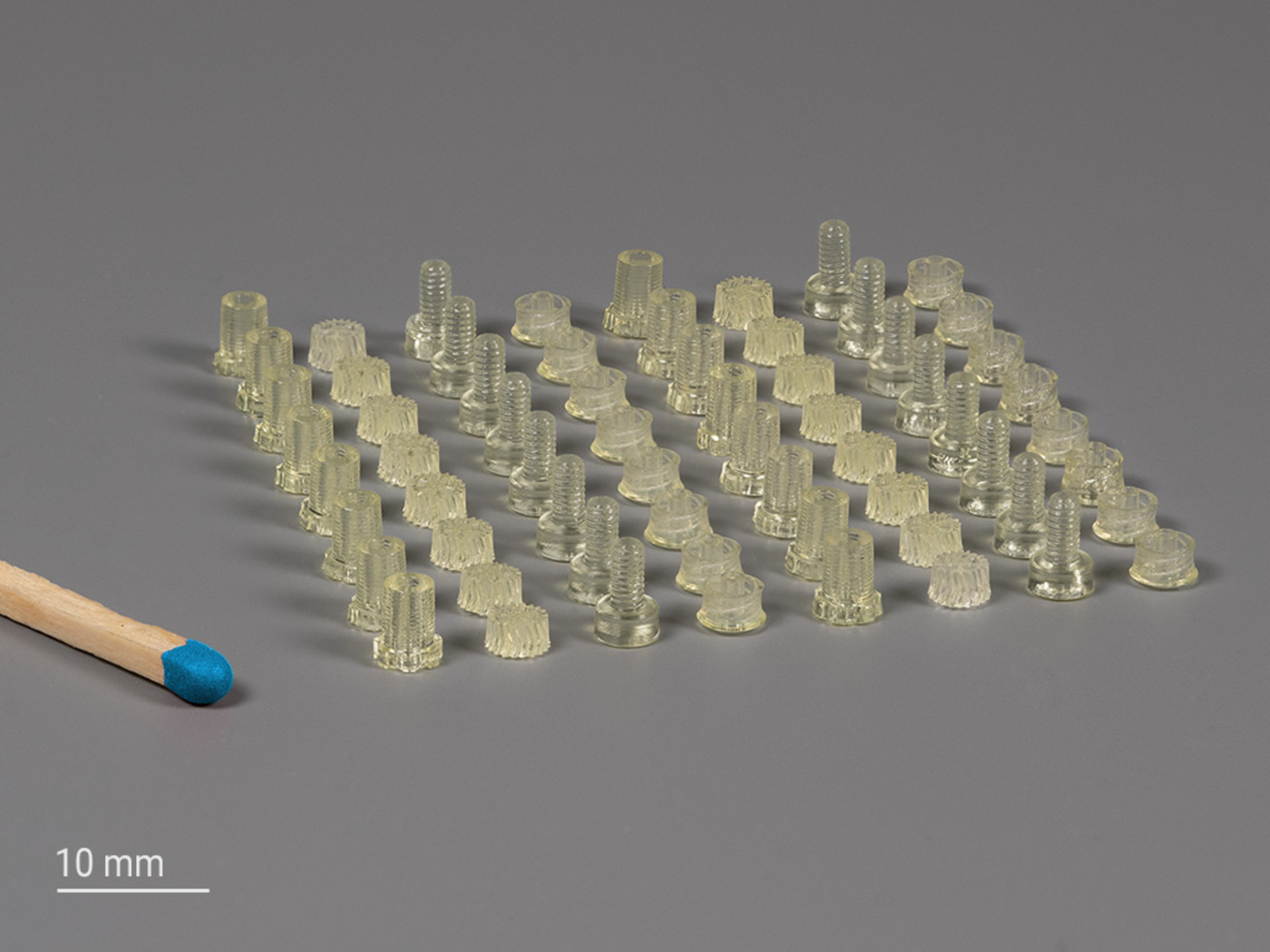

XLF Print Set

For high-precision macroscale printing

3D-printing via Two-Photon Polymerization actually focuses on the fabrication of objects on the microscale. With the XLF Print Set this manufacturing range expands from nano- and microscale structures to millimeter- and centimeter-sized objects with highest precision and shape accuracy. With the new XLF Print Set you benefit from wafer-scale batch production with print volumes up to 30 cubic centimeters in one pass.

The 5x air objective lens of the XLF Print Set, results in an increased print field diameter of up to 3,500 µm and a comparatively large working distance of 18.5 mm. In combination with extremely high scanning speeds, the XLF Print Set is ideal for a wide range of applications, such as prototyping of mechanical and microfluidic parts and structures, housings, connectors or nozzles.

Incredible range of 3D Microfabrication opportunities

Facts and figures on Quantum X shape

- High-speed 3D Microfabrication with 100 nm feature size control

- Automatic interface finder for transparent, opaque and reflective surfaces with nanometer precision

- Automated self-calibration routines for accurate laser power control and positioning

- Broad range of substrates and wafers up to 8”

- Industrial batch processing: 200 typical mesoscale structures printable overnight

- High mechanical and thermal stability through granite base and vibration damping

- Customizable system for a wide range of applications is ideal for multiuser facilities

3D Microfabrication based on two-photon polymerization for research labs and multi-user facilities with highest quality and output requirements in the fields of

- Life sciences

- Materials engineering

- Microfluidics

- Micromechanics & MEMS

- Refractive microoptics

- Diffractive microoptics

- Integrated photonics

Designed for best-in-class innovators in research and industry to unlock the full potential of high-resolution microfabrication and additive manufacturing with

- Rapid prototyping

- Batch processing and small series production

- Wafer-scale fabrication

Benchmark scores

| Surface roughness (Ra) | down to ≤ 5 nm |

| Feature size control 1 | down to 100 nm |

| Shape accuracy (Sa) | down to ≤ 200 nm |

| Batch processing | up to 200 typical mesoscale structures overnight |

| Stitching-free part diameter | up to 4,000 µm |

| Maximum scan speed | 6.25 m/s divided by lens magnification |

General system properties

| Printing technology | Layer-by-layer 3D printing based on Two-Photon Polymerization (2PP) |

| Substrates | Microscope slides (3” x 1” / 76 x 26 mm2) |

| Photoresins | Nanoscribe IP Photoresins (polymer printing) |

| Maximum print area | 50 x 50 mm² |

Peak values, only achieved under specific conditions such as printing parameters, print heads, photoresins, and designs

1 100 nm feature size control in x/y direction

Dr. Michael Thiel, Chief Science Officer (CSO) and Co-Founder of Nanoscribe

With Quantum X shape our customers benefit from the fastest and most accurate tool for 3D printing with highest-precision and unparalleled batch processing capability.

Quantum X shape

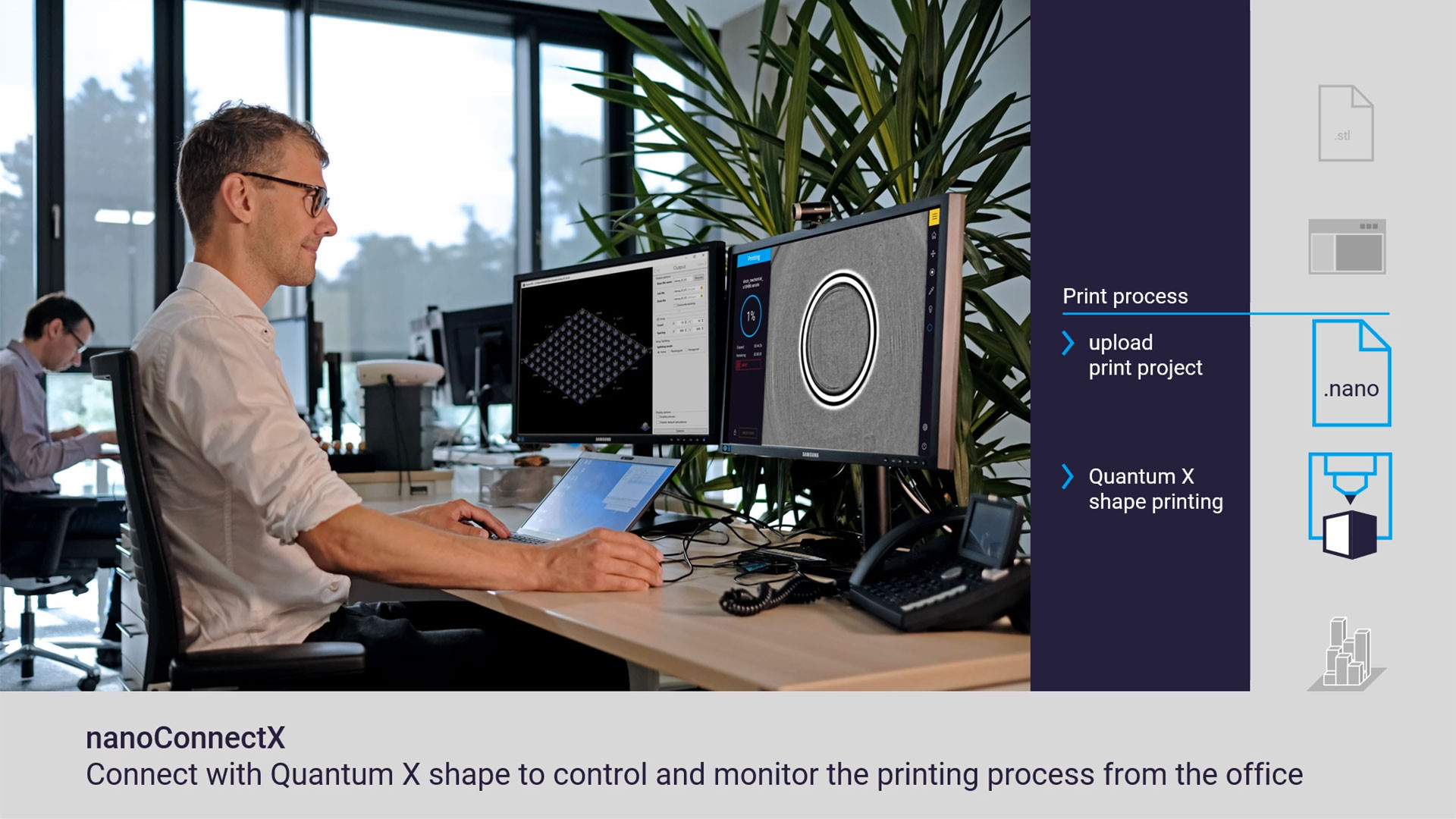

Shape your print job with our software

Field-proven software for 3D Microfabrication at wafer level

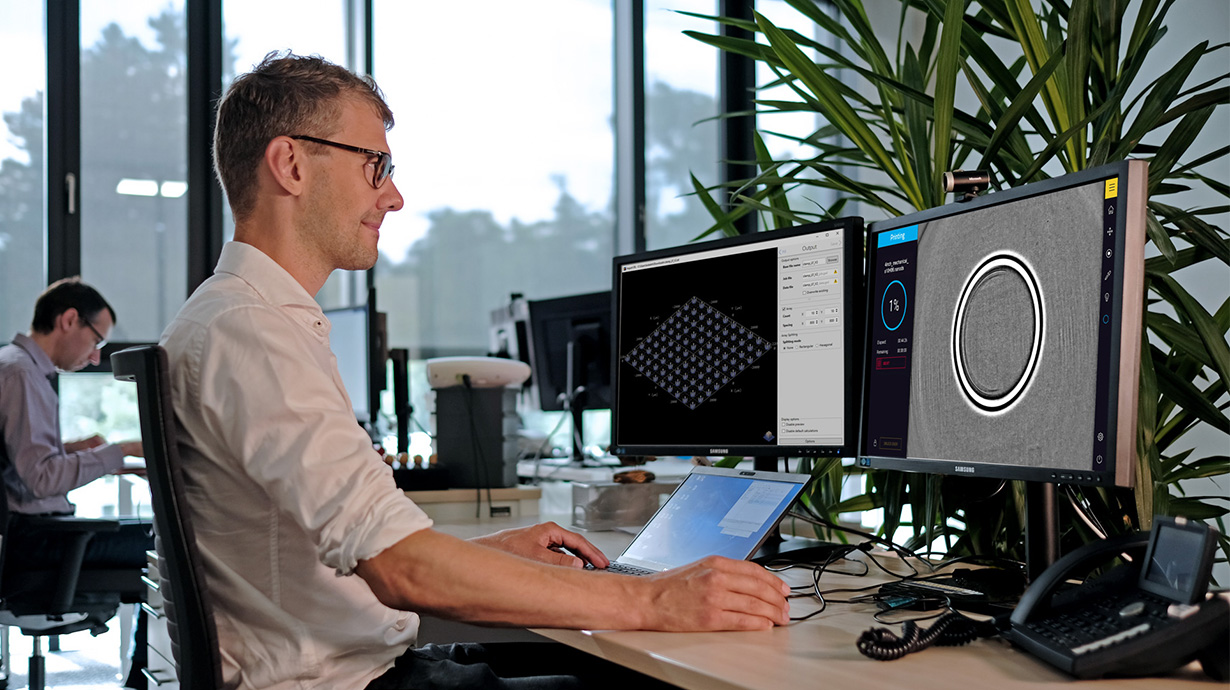

How to get from your 3D design to the final 3D-printed structure? Along Nanoscribe’s software solutions, you will make it easily to your successful print. Generate, upload, print, and monitor your print job directly from the device’s touchscreen or remotely from your PC.

Generate your 3D print job with DeScribeX: The 3D print job development software is based on the field-proven 2PP software DeScribe and guides you from the 3D CAD model import to the print job upload in just a few steps.

Generate your 2.5D print job with GrayScribeX: The print job development software also guides you from creation to uploading your individual project as a proprietary .nano file to the Quantum X system in just a few steps.

Start your print job via the touchscreen: The intuitive touchscreen menu of Quantum X easily guides you to successful printing. Also benefit from essential data such as hardware information, system status and the print progress. Furthermore, a live view of the print process via three cameras gives you a visual control at any time.

Stay connected with nanoConnectX: Start and monitor your print job from the office with the remote access software nanoConnectX. The Quantum X system is therefore well equipped for production environments and multi-user scenarios in additive manufacturing.

Software facts

DeScribeX is a print job development software for creating individual 3D print jobs for QuantumX shape. The integrated import wizard can load STL files as a widely used 3D CAD format. Pre-installed software printing parameter presets are perfect starting points that guide you to a successful print in just a few steps. The export function makes it easy to transfer the print job to the Quantum X shape remotely.

| Key feature | Benefits |

| 3D CAD model import wizard | Intuitive workflow generates suitable print job files from standard STL files |

| Print parameter presets | Ready-to-use preset parameters to achieve optimal high-precision 3D printing results right out of the box |

| Adaptive slicing | For surface refinement and improved submicrometer shape accuracy |

| Parameter sweep | For easily finding perfectly matching print parameters for new materials and applications |

| Integrated Development Environment (IDE) | Experts can generate and modify print files (GWL) for customized and sophisticated printing tasks |

| 3D preview and printing simulation | What you see is what you print! DeScribeX displays parameters such as print time, scan speed or laser power and simulates the whole printing process in detail |

| .nano files | Take advantage of the container file format that includes all necessary information for data exchange and a successful print in a single file |

GrayScribeX is a specially developed software for creating individual 2D and 2.5D print jobs for Quantum X microfabrication systems. You can import standard grayscale images or CAD models that are automatically converted into grayscale images. A smart software routine translates the gray values from the imported design into the heights of the print object and precisely sets the calibrated print parameters.

| Key feature | Benefits |

| Import of 16 bit grayscale images and CAD files | Use standard image files .bmp and .png as well as the CAD format .stl |

| Remote upload of print jobs | Work and connect remotely with Quantum X shape from the office |

| Add, remove and duplicate structures to the print job | Create print jobs of different structures in one file |

| Rescale your structures and create arrays | Modify the structures to meet individual requirements for the corresponding application |

| Field-proven print parameter presets | Benefit from ready-to-use preset parameters for straightforward printing of any grayscale design |

| Internal calibration files | Easily translate your gray values into the corresponding writing parameter |

| .nano files | Take advantage of the container file format that includes all necessary information for data exchange and a successful print in a single file |

Control and monitor the 2PP system using the Quantum X shape front panel touch screen, the graphical user interface (GUI). It guides you to a successful print in just a few steps. Select your print project, then load your substrate and start printing.

| Key feature | Benefits |

| Three live cameras | Monitor the direct laser writing process online from three perspectives and always be up to date on the current status of your print job |

| Stage control in x, y and z direction | Move the stage to any position on the substrate to define your print area |

| User-friendly print setup | Select resin and substrate, and start the print job with just one click |

| Project list | Keep track of the entire print job history |

| Automatic interface finder | Identify the interface of the substrate with submicrometer accuracy |

nanoConnectX is the remote access software for the Quantum X systems. It brings all the functions and display capabilities of the touchscreen to any computer connected online.

| Key feature | Benefits |

| Remote access to the system | Connect Quantum X shape to your computer, no matter where you are |

| Use all features of the touchscreen | Prepare, control and monitor your print jobs from any location |

| Upload and download print jobs and reports | Take advantage of a direct access from your computer to print-related files |

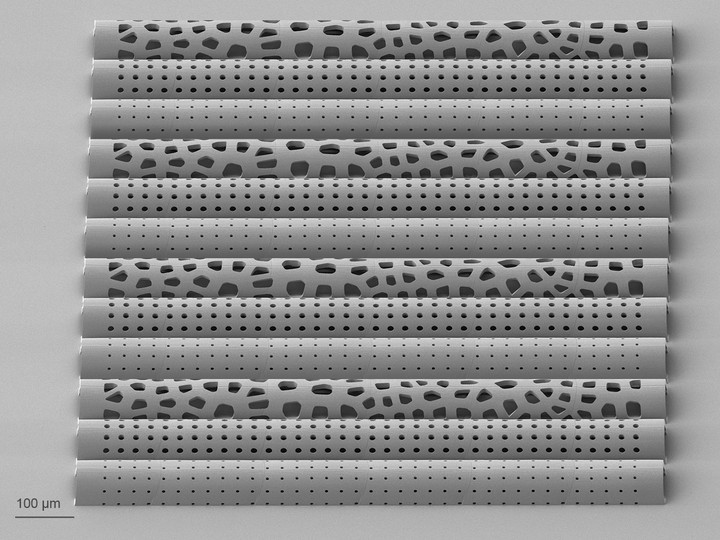

How to reshape microfabrication

Quantum X shape offers true design freedom for any 2.5D and 3D microfabrication task. With the new high-resolution 3D printing system you can print high aspect ratio structures, vertical walls, undercuts and other challenging features. Quantum X shape is the ideal high-precision microfabrication tool for applications in life sciences, material engineering, micromechanics and other microtechnology fields.

Look how

precision, output and usability come about ...

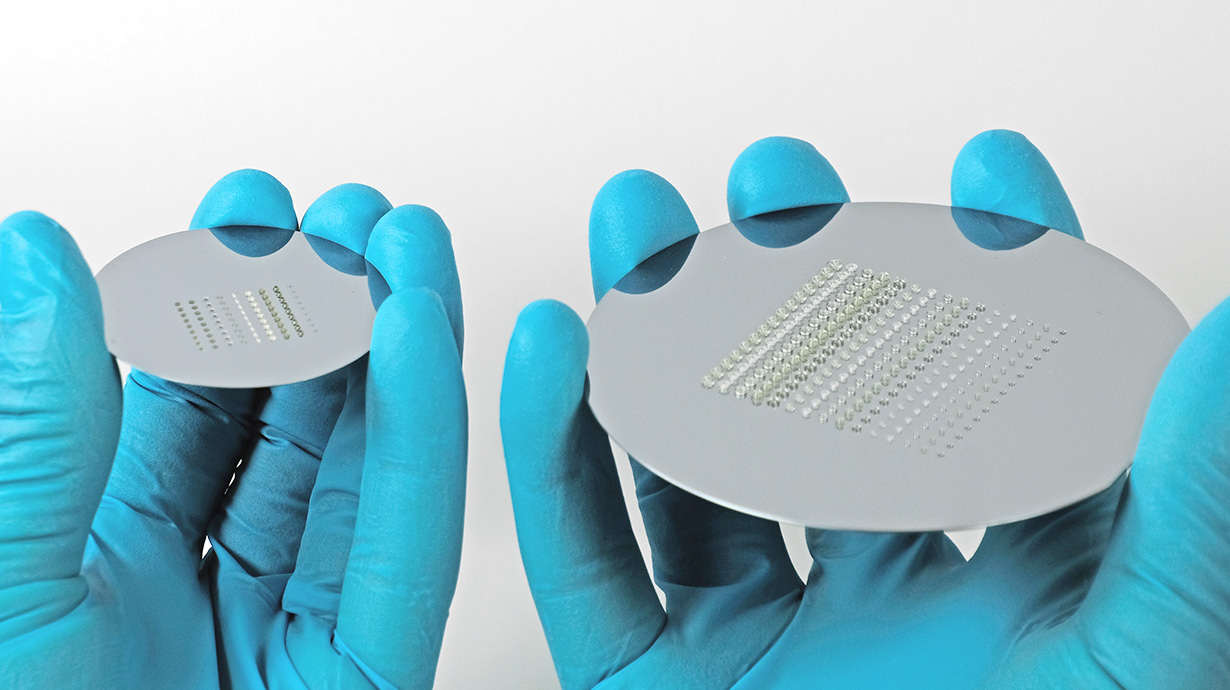

Why is Quantum X shape so highly suitable for wafer-level batch production?

Quantum X shape is part of the industry-proven platform Quantum X and advances wafer-scale microfabrication. The two-photon lithography system can process silica substrates and silicon wafers up to 6”. Processing standard wafer and different substrate types is of great importance for post-processing steps and for the integration into existing industrial manufacturing process lines.

In contrast to most Two-Photon Polymerization (2PP) systems, Quantum X shape prints in an upright position. In combination with the proprietary photoresin dispenser, exact dosing of the printing material is guaranteed throughout the entire printing process and even on large areas.

As a result, up to 200 typical structures can be printed overnight on a fully addressable print field of 50 x 50 mm².

How much can the advanced galvo mirror system enhance high-precision 3D printing?

The galvo system of the Quantum X shape has an optimized operation range and enlarges the print field with 1,750 µm towards its physical limits. This optimized and calibrated print field is crucial for stitching-free printing of mesoscale objects at highest speed rates. In addition, smart system algorithms control the galvo system by accelerating and decelerating the galvo mirrors in sharp corners and edges. At the same time, the laser power is adapted to the scan speed and ensures a constant exposure dose of each volume during the printing process. This is the only way to ultimately achieve optimum printing speed with maximum accuracy. Complementarily explained with a simple example: The galvanometer control unit is like a racing car that accelerates and brakes on a curvy race track on an ideal trajectory and drives at highest speed on straight passages.

To learn more about high-precision 3D printing, read our whitepaper about additive manufacturing based on Two-Photon Polymerization. Login or register for free.

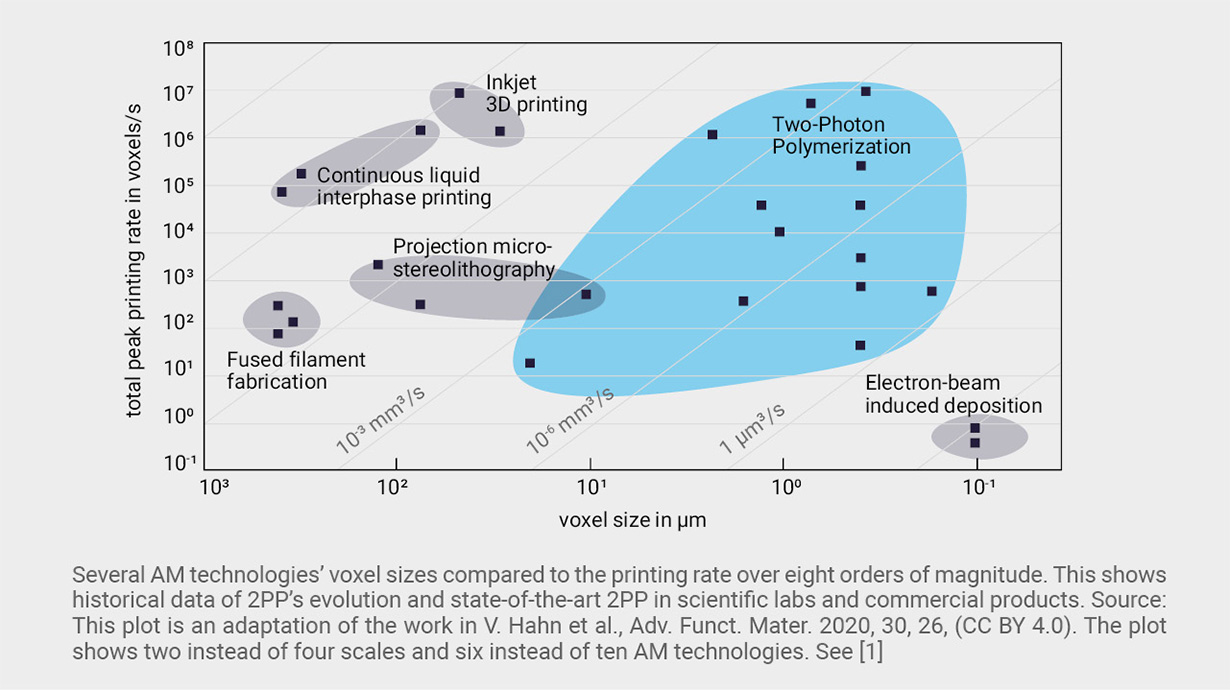

How well does Quantum X shape compare with other microfabrication technologies?

Our whitepaper offers deeper insights into the performance of various high-precision 3D printing technologies. You can find it in the premium section on our website. Login or register for free.

The metric for print speed refers to the rate in voxels printed per second and is an indicator of how digital information is converted into solidified material. The 2PP system Quantum X shape features an extremely high speed of 1 million voxels per second.

The plot shown here compares Two-Photon Polymerization (2PP) to common additive manufacturing technologies in terms of printing rates and feature sizes. Measured by the absolute volume printing rate of 2PP, the serial process seems to lag behind the speed of other technologies. However, the technology features a high voxel printing rate compared to the fine voxel sizes it resolves.

How can you print structures at different scales without sacrificing precision or shape accuracy?

Quantum X shape is designed for rapid prototyping and wafer-scale 3D printing on the nano-, micro-, and mesoscale. Different, well-matched print sets consisting of objective lenses, suitable resins and well-tuned print parameter presets ensure to cover this wide range of different scales. The software-based print parameter presets include slicing and hatching, laser power and galvo settings and are therefore optimal starting points. There are four different print sets available:

- The Small Features Print Set features a 63x objective and is designed for highest precision with submicron feature sizes.

- The Medium Features Print Set is specially tailored to the high-speed fabrication of microscale parts. Typical structures, such as microlenses with a size of several hundreds of micrometers and a surface roughness (Ra) of less than 5 nanometers become possible.

- The Large Features Print Set extends the benefits of high-resolution 3D printing to mesoscale structures with precision in the micrometer range.

- The Extra Large Features Print Set expands the 3D Microfabrication range from nano- and microscale structures to millimeter- and centimeter-sized objects.

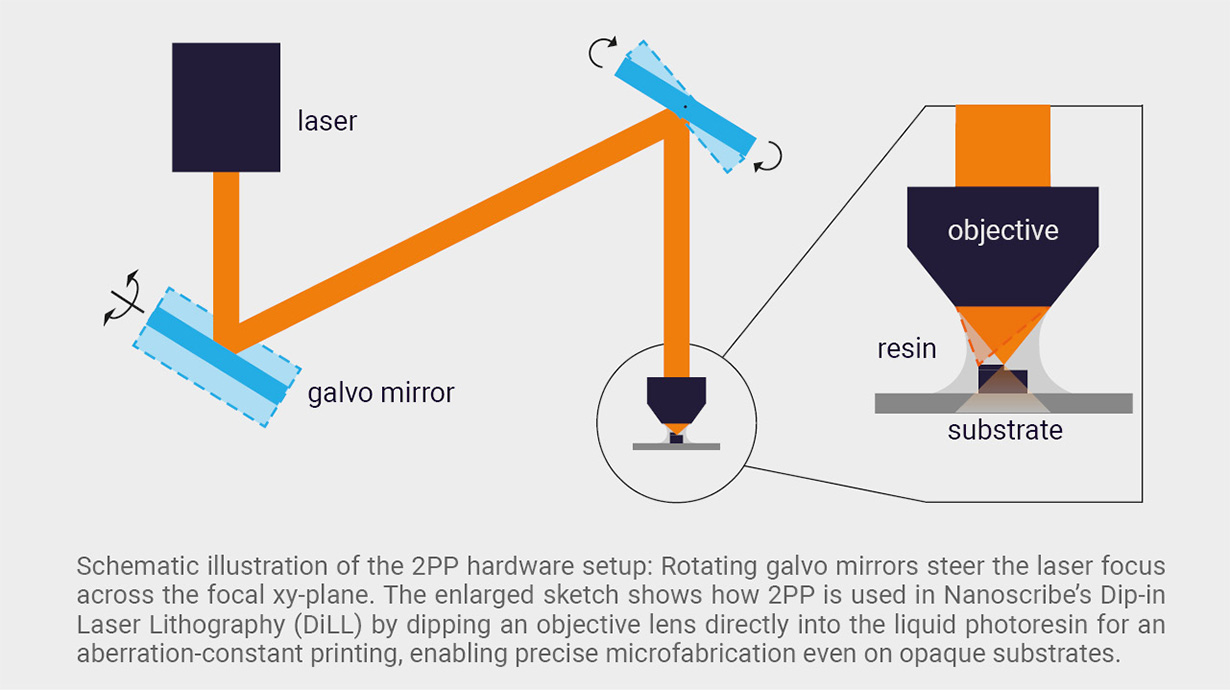

What are the unique advantages of the proprietary Dip-in Laser Lithography (DiLL)?

Dip-in Laser Lithography (DiLL) is the standard printing configuration of Quantum X shape. Nanoscribe invented this technology for 3D Microfabrication with the highest precision and the lowest aberration on the market. In this configuration, the objective lens is immersed in the photoresin, which also serves as an optical immersion medium. The refractive index matching between the focusing optics and the print material guarantees ideal, aberration-free focusing with the highest resolution in 2PP-based 3D printing. Furthermore, the writing laser is not focused through the substrate (e.g. oil immersion configuration), but writes the print object directly onto the substrate. Consequently, the working distance of the focusing optics does not limit the height of the 3D-printed object, which is especially beneficial for printing macroscale objects.

What range of different substrates can be used?

Quantum X shape’s advanced interface finder includes two complementary modes for reflection and fluorescence detection of the substrate surface. In combination with the Dip-in Laser Lithography (DiLL) configuration, a wide range of reflective (e.g. silicon wafers), transparent and opaque substrates (e.g. glass and polymer substrates) can be used. In addition, the DiLL configuration enables to print on standard substrates such as microscope slides and wafer formats from 1” to 6”. Nanoscribe’s substrate holders guarantee a precise fixation of the continuously growing range of substrates during the printing process.

What site conditions do our devices need for optimal operation?

Quantum X shape is the ideal tool for high-speed 3D Microfabrication of objects with submicron feature sizes, surface roughness profiles of 5 nm and less and nanoprecision. This highest precision in 3D printing can only be exploited to the maximum by taking some precautions with regard to the microfabrication system itself and the installation site. Quantum X shape should have its fixed place in a room with stable room temperature and humidity. The direct laser writing system comes with a heavy granite base to reduce the influence of vibrations and temperature fluctuations of the environment. Nevertheless, it is important to install the high-resolution 3D printer in a location that minimizes external vibrations. For the handling of the UV-sensitive photoresin outside the two-photon lithography system, we recommend to equip the room with yellow light and to meet basic requirements of a chemistry lab to handle organic solvents for the print development process properly.

If you would like to get an idea of how the Quantum X shape work environment can look like, contact us and visit our Microfabrication Experience Center here at Nanoscribe or book your online tour.

Why is it so easy to integrate Quantum X shape into production environments and multi-user facilities?

The advanced autofocus system reliably finds the interface of almost any substrate with maximum accuracy and repeatable print results. Three live-view cameras facilitate process control and monitoring. An automatic dispenser applies the correct amount of photoresin onto the substrate, reducing workload and enabling remote operation. To simplify switching between hardware configurations, the Quantum X shape automatically detects the printheads and substrate holders. Quantum X shape software controls and monitors print jobs in real time and supports intuitive operation through an interactive touchscreen control panel, or remotely from the office via the remote access software nanoConnectX. This remote access also simplifies the work of entire user groups, e.g. members of a research group or a department, with a single or multiple direct laser writing systems, each of them accessing the Quantum X shape from their own computer.

Why are printing materials so crucial for expanding the opportunities in 3D Microfabrication?

Quantum X shape is an open system with regard to printing materials and thus equally suited for the use of custom or third-party materials. However, Nanoscribe offers a product line of liquid negative-tone resins that are specially designed for Two-Photon Polymerization based 3D printing. These application-specific and ready-to-use printable materials provide submicrometer resolution as well as excellent shape accuracy and stability. With the polymer-based IP Photoresins, demanding applications such as submicron structures, complex 3D architectures, optical-quality surfaces, soft and elastic elements, high-speed mesoscale fabrication, or biocompatible microparts become possible. GP-Silica, an inorganic fused silica nanocomposite and part of the unique Glass Printing Explorer Set, is made for innovative direct 3D printing of glass microstructures.

Learn more about our IP Photoresins or GP-Silica and their potential for tomorrow’s applications.

Quantum X shape

More precision, output, usability.

Shaping success.

We would be pleased to make you a customized offer.

For this, clarify the detailed issues with our sales experts.