Integrated photonics by 3D Microfabrication

The design freedom of Two-Photon Polymerization (2PP) based 3D printing enables to additively manufacture optical interfaces, waveguides and hybrid refractive-diffractive optics on various prepatterned substrates. Benefit from the high-precision positioning systems in our technology to precisely integrate complex microstructures where needed.

3D Microfabrication of complex optical structures on pre-existing patterns

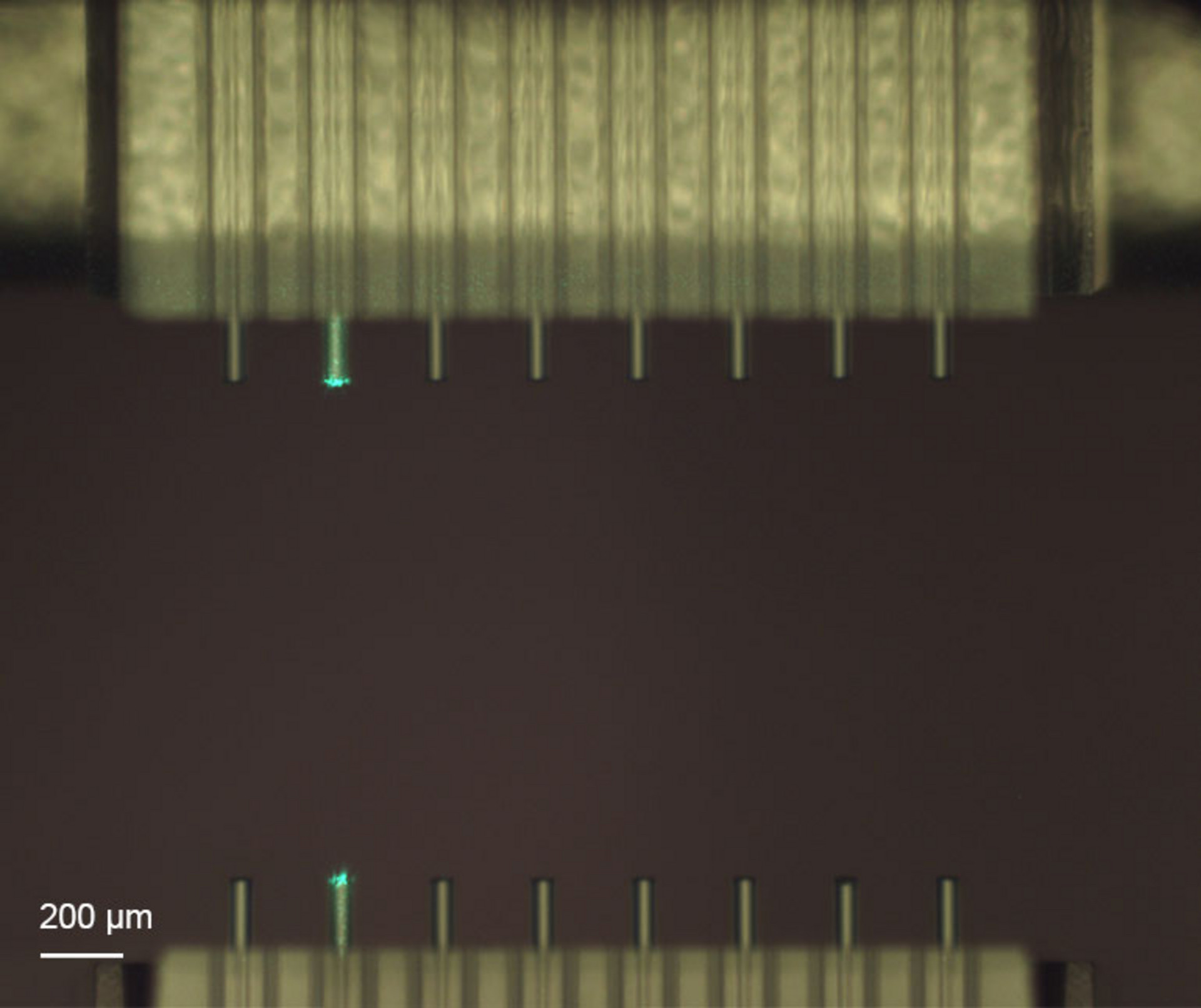

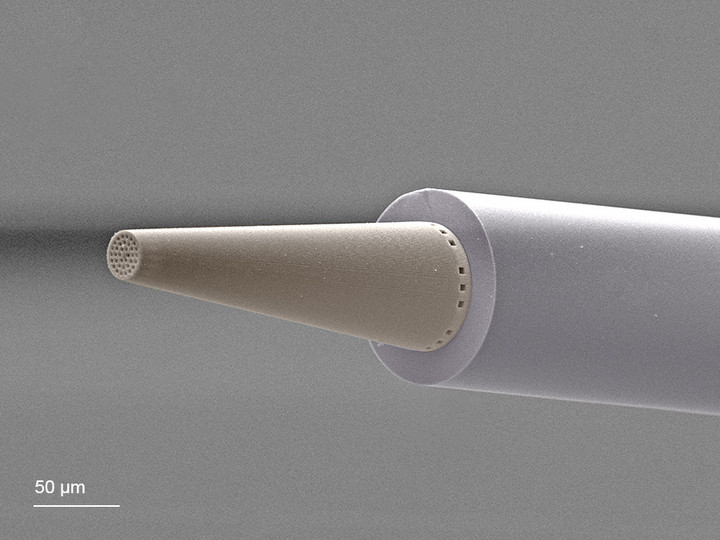

The miniaturization of optical and optoelectronic components is decisive for enabling data communication and telecommunication as well as sensing and imaging applications. The realization of freeform lenses, mirrors and other novel designs by conventional micro-scale 3D printing lacks sufficient resolution and optical surface quality. Two-Photon Polymerization allows to print optically transparent microstructures with smooth surfaces along a lean process. The technology is not only used to fabricate microparts on plane substrates but also to directly print complex structures precisely on pre-existing patterns and topographies, e.g. on photonic integrated circuits, on optical fiber tips and on premanufactured wafers. This method enables miniaturization and assembly-free fabrication of optical interfaces with high-precision in-situ 3D microprinting on various materials, such as InP, SOI and Si3N4.

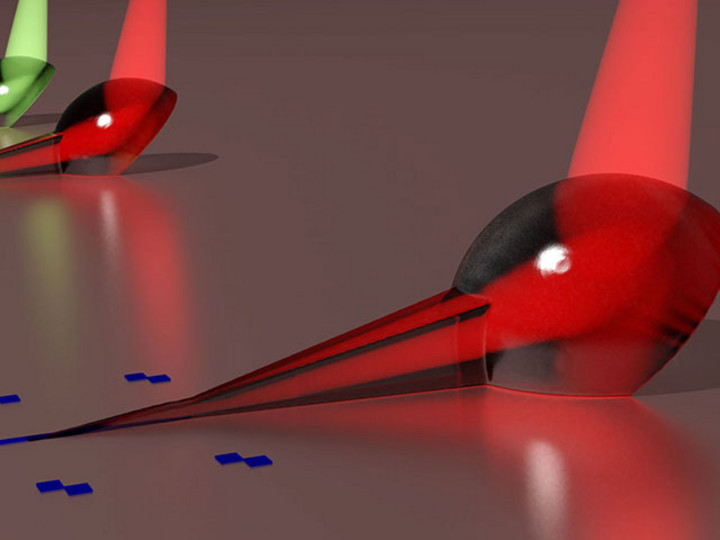

For example, it is used to print freeform microoptical components directly onto chips, enabling the connection of multiple fibers to a chip. The light in this case must be collected, redirected parallel to the chip plane and then transferred to a narrow waveguide. For this purpose, the inherent design freedom of Two-Photon Polymerization enables to combine elements such as a spherical lens to collect light from the fiber facet with a taper to transfer it into the waveguide.

Nanoscribe’s expertise in high precision 3D Microfabrication and more than a decade of experience in the field of integrated photonics resulted in Quantum X align, the best-in-class 3D printer with nanoprecision alignment system. This new two-photon lithography system enables microfabrication of freeform lenses on predefined positions of photonic components and platforms.

Our aligned 3D printing competence is also sought after in several innovative research projects, such as MiLiQuant, HandheldOCT and PHOENICS.

Deep insights into integrated photonics

for data communication

A new publication “Integrated Photonics for Data Communication Applications” has been published by Elsevier. The book introduces readers to the key concepts and design principles of integrated photonics. It also provides an overview of key performance metrics and manufacturing methods from advanced photonic devices to integrated photonic circuits.

In Chapter 12.9, Jörg Smolenski, Business Development Manager at Nanoscribe together with Professor Wolfram Pernice and Helge Gehring from the University of Münster present the process principles and applications of the 3D printing of microoptics on dies for integrated photonics, such as tapers, lenses, and free space microoptical couplers.

The chapter explains the working principle of Two-Photon Polymerization (2PP) and the enhanced and advantageous printing process of Two-Photon Grayscale Lithography (2GL®) for the fabrication of microoptics. It also offers application scenarios where fiber-to-chip coupling structures come into play and provides an outlook on future developments in photonics packaging.

Integrated Photonics for Data Communication Applications

Madeleine Glick, Ling Liao and Katharine Schmidtke

Get inspired by 3D Microfabrication artworks

Integrated photonics

application opportunities

Looking to assess the opportunities for your integrated photonics project? Explore the application options of our 3D Microfabrication solutions and view the 10 most recent scientific publications in materials engineering from over 1,800 peer-reviewed journal articles.

To view the details of the publications and to find more research topics and applications in which Nanoscribe 2PP-based 3D printing systems are already successfully used, just enter our premium resources – log in or register for free.

View more innovation projects

You get more publication examples and deeper insights within our premium resources. Via a keyword-underpinned database you find more than 1,800 scientific publications of our customers in specific application areas. Make use of the tool to gather valuable know-how and background information about the manifold application options.