Advanced microoptics with 3D design freedom

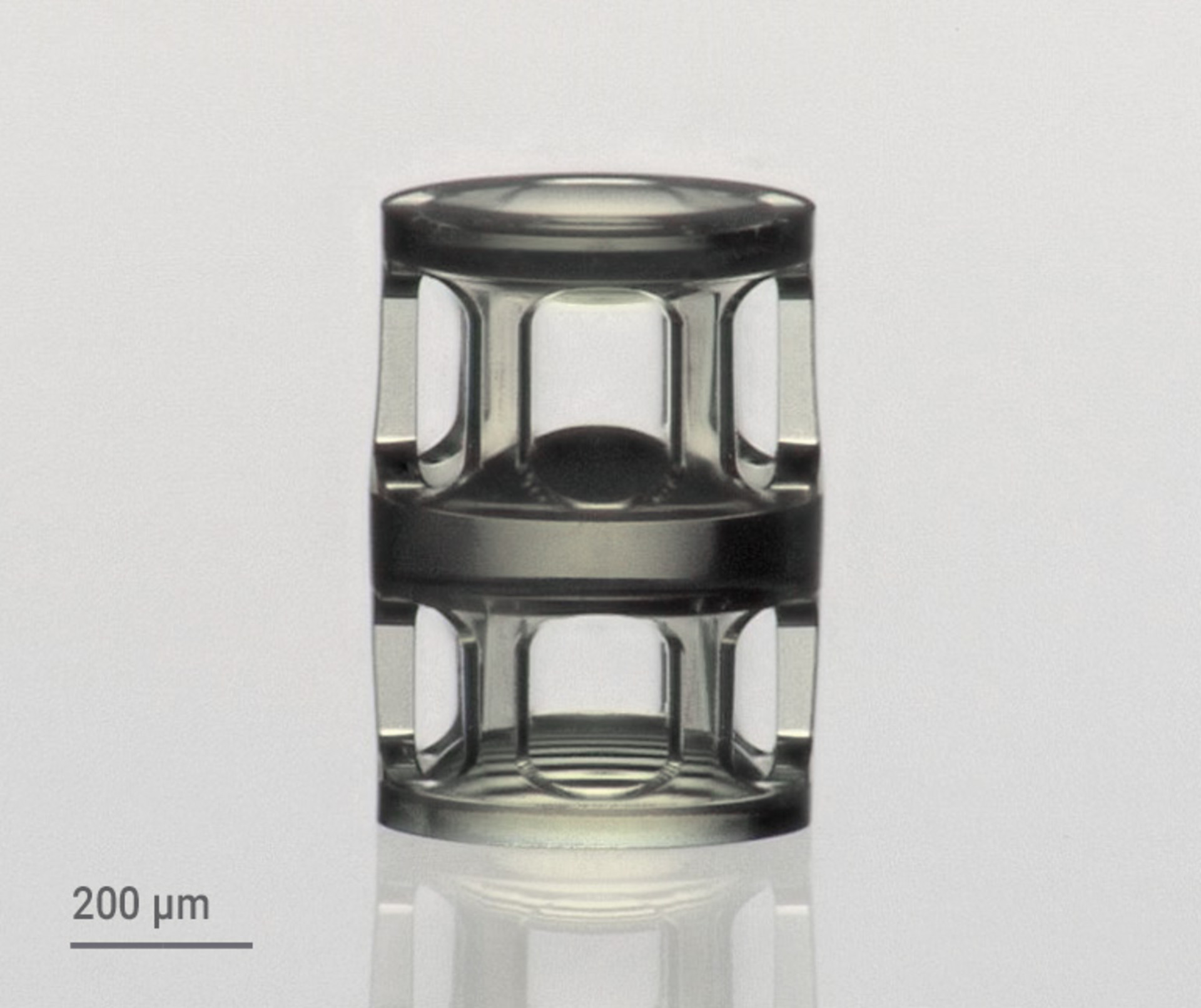

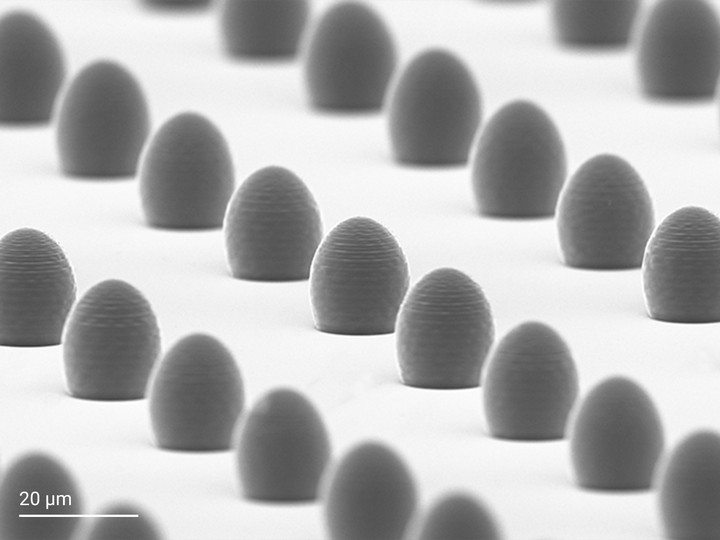

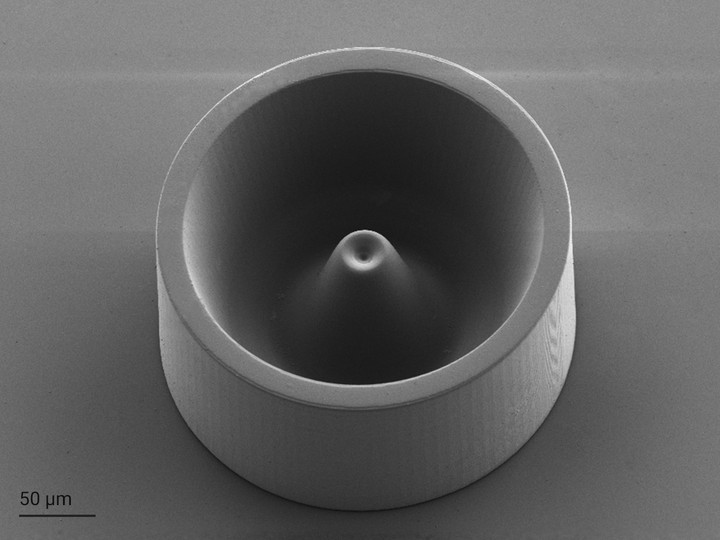

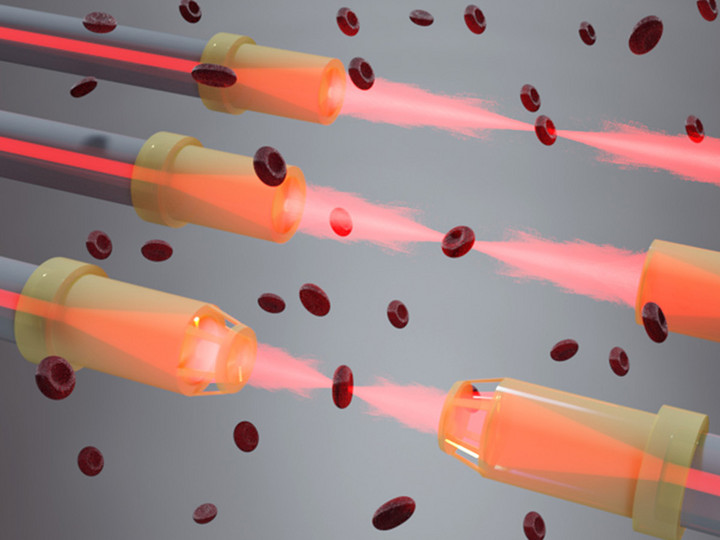

Additive manufacturing on the microscale enables to go beyond classical microoptical designs. Benefit from the extraordinary capability of Two-Photon Polymerization to shape spherical, aspherical, freeform and even compound 3D microoptics with surfaces and shape accuracy in truly outstanding optical quality.

The next level of additively manufactured microoptics

With our high-resolution 3D printers you can materialize nearly any three-dimensional shape with optical-grade surfaces. This effectively circumvents limitations imposed by mechanical tools and geometrical or process design constraints common to subtractive techniques. Single microlenses, hybrid and freeform optics and compound lens systems can be printed without the need of post-print assembly of individual components.

Using our microfabrication systems Quantum X shape or Photonic Professional GT2, 3D microoptics can be fabricated with ease. Quantum X shape is the fastest and most accurate 3D printer in class while Photonic Professional GT2 is the most mature high-resolution 3D printer in the field. Take advantage of their capabilities in rapid and ultra-precise microfabrication. Print on a wide choice of suitable substrates including glass, silicon wafers, photonic and microfluidic chips. With Quantum X align, on-chip and on-fiber printing is possible.

Nanoscribe IP Photoresins also present options for the fabrication of advanced microoptics. The IP-S photoresin is well suited for the printing of microstructures with high shape accuracy, very smooth contours and optical quality surfaces. For example, microlens arrays printed with IP-S achieve a shape accuracy better than 1 µm and a surface roughness of less than 10 nm Ra. Moreover, the new IP-n162 has a high refractive index of 1.62 and high Abbe number of 25. The optical properties of IP-n162 are comparable to those of optical polymers typically used in injection molding, for example, polycarbonates and polyesters.

Get inspired by 3D Microfabrication artworks

Microoptics

application opportunities

Looking to assess the opportunities for your microoptics project? Explore the application options of our 3D Microfabrication solutions and view the 10 most recent scientific publications in materials engineering from over 1,800 peer-reviewed journal articles.

To view the details of the publications and to find more research topics and applications in which Nanoscribe 2PP-based 3D printing systems are already successfully used, just enter our premium resources - log in or register for free.

View more innovation projects

You get more publication examples and deeper insights within our premium resources. Via a keyword-underpinned database you find more than 1,800 scientific publications of our customers in specific application areas. Make use of the tool to gather valuable know-how and background information about the manifold application options.