What are the challenges and difficulties in glass manufacturing and what is special about the processing of the composite?

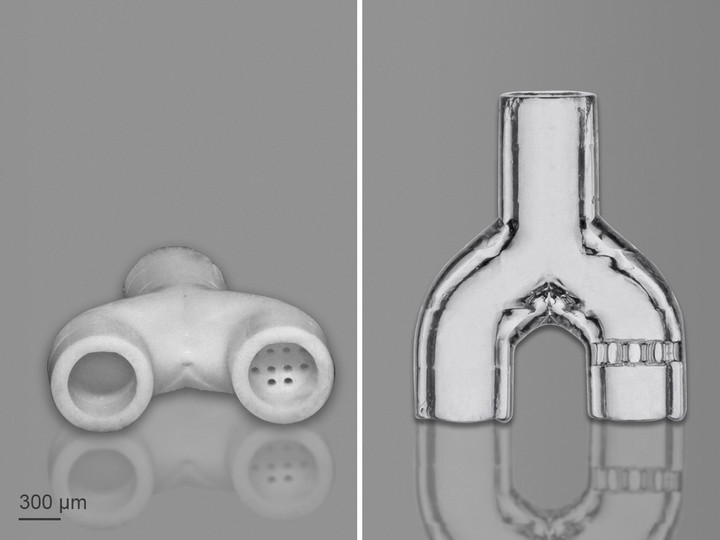

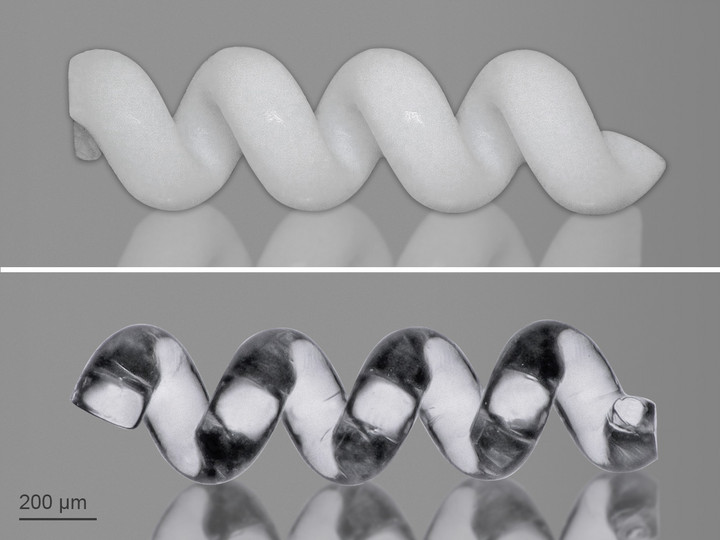

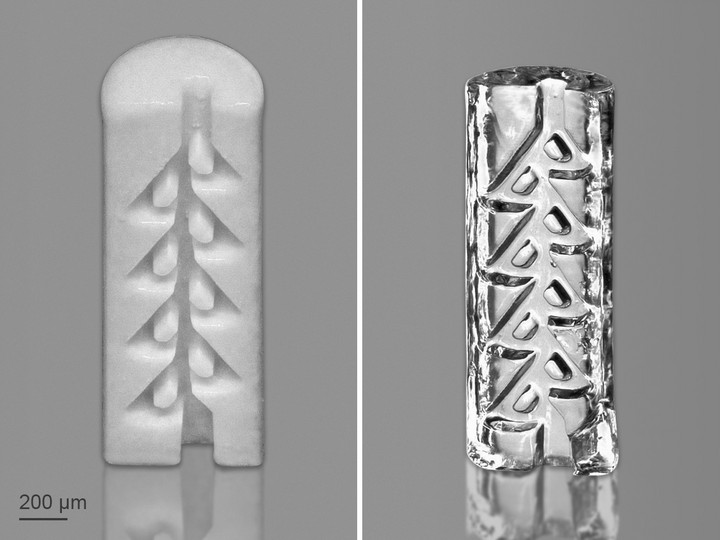

Bastian Rapp: In short, with the nanocomposite approach, glass can be structured like a polymer. The term Glassomer goes back to precisely this fact: You structure glass but pretend that it is actually just a polymer that you are processing. The approach is very similar to building a sandcastle. You take glass in its smallest form – tiny grains of sand – and bind them together, in our case, with small amounts of a polymer. This creates a free-flowing liquid that essentially turns into glass after curing and post-processing. Until you have fixed the final shape, you work with a polymer during fabrication and thus with polymer processing techniques. Once you have defined the shape, the polymer-silica nanocomposite undergoes a post-treatment that removes the polymer and leaves only the silica particles. In the final step, you fuse them together to get a dense piece of glass. The printing material’s name of this polymer-silica nanocomposite for Two-Photon Polymerization (2PP) is GP-Silica that we jointly developed with Nanoscribe in the research project OptoGlass3D.

What an achievement. Can you explain in more detail what GP-Silica as a nanocomposite consists of and what is advantageous about it in terms of processing?

Bastian Rapp: The photoresin’s formulation consists of an organic binder, which essentially is a polymer that can be cured to a solid, cross-linked piece of plastic when exposed to light. Within this organic binder, we suspend a large amount of silica nanoparticles. The nanoparticles are so small that they remain in suspension – the gravitational forces are too small to let them sink. So essentially you have a clear liquid with a large amount of tiny sand particles in it.

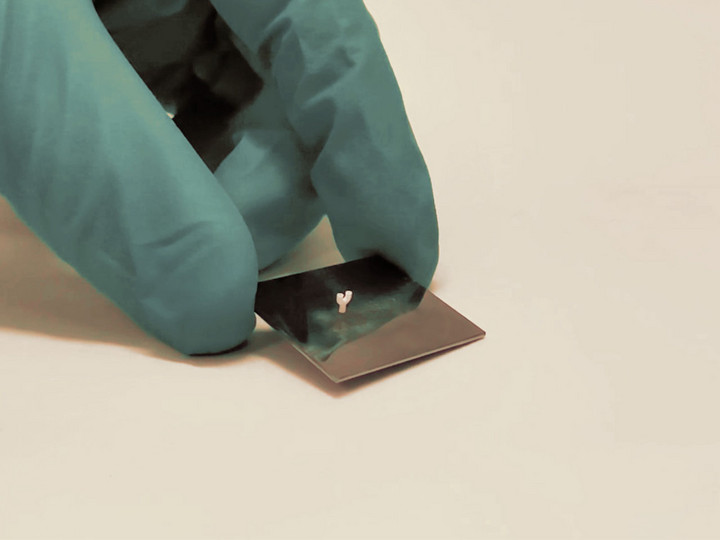

Alexander Quick: And to make the printing material perfectly suited to the high-precision printing process based on 2PP, our new photoresin GP-Silica contains this special suspension and a few other ingredients. The liquid photoresin thus contains “initiating” components that effectively trigger the curing reaction. Curing itself, similar to other Nanoscribe IP Photoresins, is achieved by radical polymerization, a well-established process in 2PP. The printed “green part” is a composite material consisting of the polymer and silica nanoparticles, which is processed into fused silica glass in a final thermal post-treatment. In a nutshell, we use the processing advantages of polymer technologies to create glass structures.