Heart attacks are one of the leading causes of death in the world. 3D Microfabrication can bring life science research a big step closer to the concept of regenerative medicine for the curing of diseases in this field. Boston University scientists contributed to this goal with a microfluidic heart-on-a chip platform fabricated by Two-Photon Polymerization (2PP). This paves the way for fundamental studies of heart tissue and eventually enables the fabrication of tissue that can be implanted into the beating heart.

3D-printed heart-on-a-chip for driving research on cardiac diseases and drug delivery

Imagine that you could create tissue patches and incorporate them into organs like our heart. Without context, this idea might sound like Mary Shelly’s famous novel of Frankenstein’s monster. But in reality, research in this area can help millions of patients regain their quality of life as they recover from serious medical issues and diseases. The muscle tissue in our heart, primarily composed of cardiac myocytes, can be irreversibly damaged during a heart attack and this tissue will not regenerate itself. An ambitious goal in current life sciences research is to create functional macroscale heart tissue patches from patients’ own stem cells. These engineered tissues cells could replace the diseased or damaged muscle after a heart attack and help people to return to a normal life.

3D printing a heart on a chip

Scientists at Boston University have recently developed a soft and mechanically active cell culture platform to study heart muscle tissue in a customizable 3D microenvironment. This multifunctional toolbox allows cardiac tissue to be grown in a 3D environment and its self-assembly to be observed at cell attachment sites on the vertical walls of the chip. An integrated electronic sensor measures the forces generated by the contractions of the cultivated heart cells. Furthermore, the researchers integrated a mechanical actuator into the chip to passively stretch the cultivated tissue. With this actuator, the scientists investigated the influence of constant and dynamic mechanical strain on the heart tissue.

Standard soft lithography meets Two-Photon Polymerization

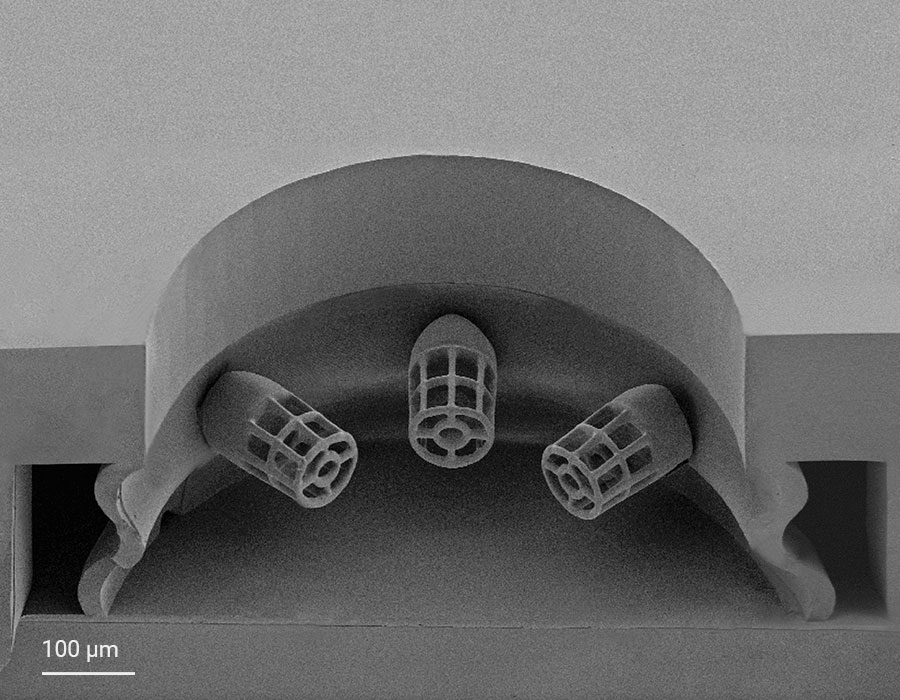

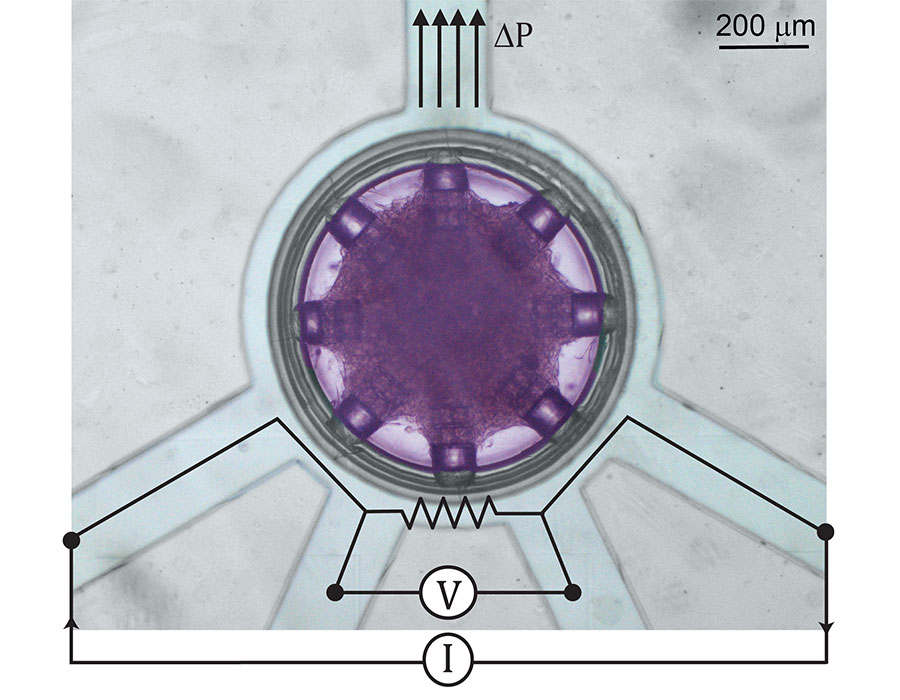

The heart-on-a-chip platform consists of an inner circular seeding well containing the cardiac tissue surrounded by a microfluidic actuator. Cell attachment sites are printed directly on the vertical walls of the seeding well.

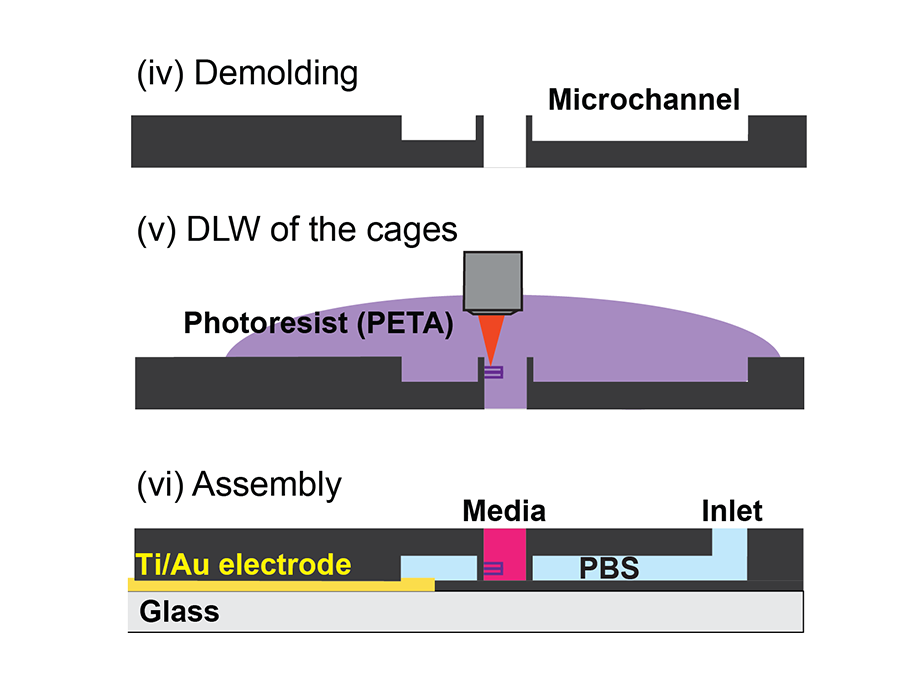

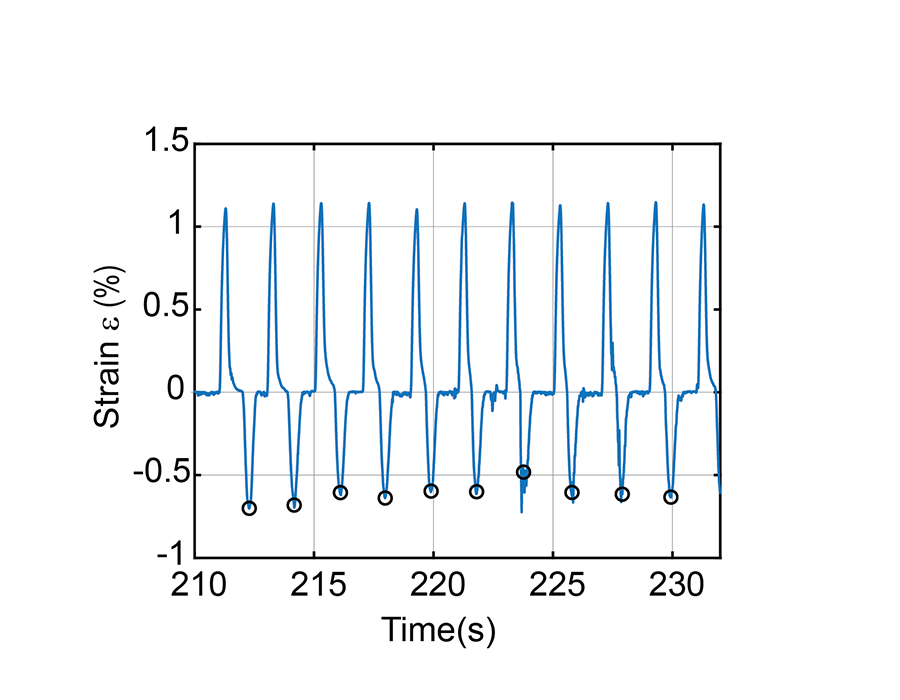

The microfluidic actuator is the key element of the platform and it also acts as a strain sensor. When a fluid flows through the channel, the thin partition between the channel and the seeding well expands. This mechanical strain is transmitted to the cultivated tissue, growing at the attachment sites of the platform. At the same time, the strain of the thin partition wall can be recorded with an electronic readout.

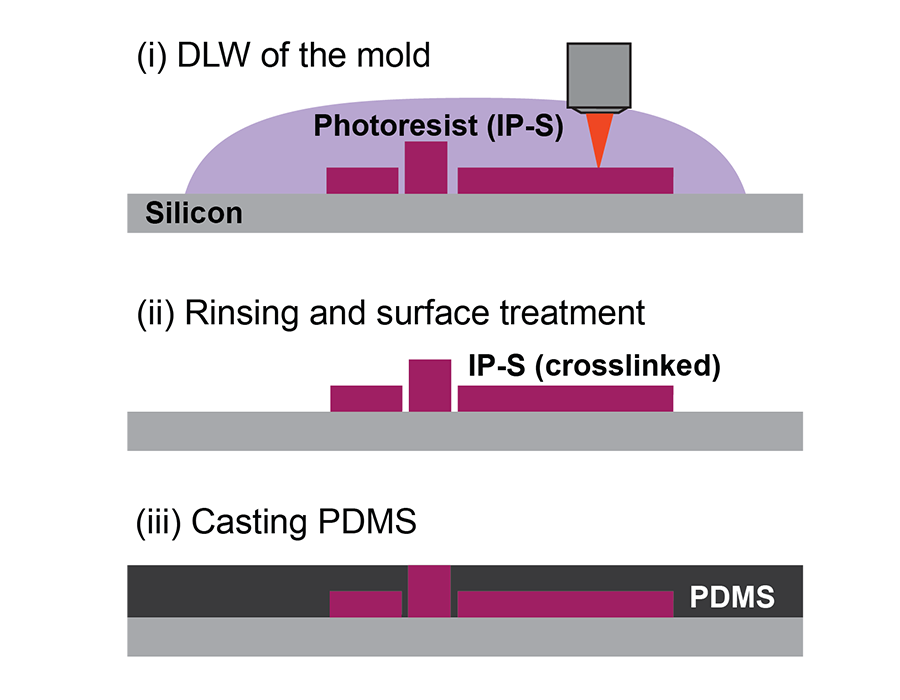

The scientists fabricated the seeding well and surrounding microfluidic channel using PDMS soft lithography. As a first step, they fabricated the negative master mold using Nanoscribe’s 2PP technology. The direct laser writing approach enabled the researchers to fabricate the thin, high aspect ratio membrane wall that separates the outer microfluidic channel from the inner seeding well. The real strength of the 2PP system comes into play after the researchers molded the PDMS seeding wells from the negative master. The scientists again used the Nanoscribe to print microcages made of a customized resin directly onto the thin vertical membrane walls of the seeding well. These microstructures serve as anchoring points for the cells and define the geometry of the freestanding cardiac tissue. In a final step, the heart-on-a-chip platform is bonded to a glass substrate with integrated electrode contacts for the electronic strain-read out.

Advanced cell alignment studies through synchronized heart beats

In their study, the researchers fabricated platforms with different numbers of cell attachment sites and observed how the geometry of the free-standing cardiac tissue in the seeding well changed based on their position and number. After four to five days, the cardiac tissue began to beat spontaneously, and the mechanical force exerted by the cells on the attachment cages can be monitored by the integrated strain sensor. As a highlight of their research study, the scientists periodically stretched the heart tissue with the microfluidic actuator. After about three minutes, the spontaneous contractions of the cardiac cells synchronized with the stimulated beat. With these exciting results, the researchers are one step closer to their goal of transplanting these tissue patches onto a beating heart and synchronizing them with the beat of the patient’s own heart.

New opportunities for tissue engineering and regenerative medicine

This goal still requires a lot of research. Nevertheless, using Nanoscribe’s Two-Photon Polymerization technology, researchers have been able to fabricate a platform that enables detailed studies and new insights about cardiac tissue.

This new heart-on-a-chip platform from the Boston researchers is an excellent example of how 2PP-based microfabrication can advance applications in life sciences. The scale of biological tissue and submicron resolution of 2PP-based 3D printing are perfectly suited to mimic the natural environment. Coupled with the development of biocompatible materials for 2PP-based 3D printing, many other exciting applications in tissue engineering, cell biology and regenerative medicine can be expected.

As a part of the BICO Group, Nanoscribe has anticipated the life sciences’ needs for 3D Microfabrication and has launched several printing materials such as IP-PDMS and, in collaboration with our partner Xpect Inx, the N100 biomaterial inks. Stay tuned for new exciting developments coming soon.

Would you like even more insight into this exciting project? Then read the scientific publication here: Direct laser writing for cardiac tissue engineering: A microfluidic heart on a chip with integrated transducers

The complete publication and further scientific publications on hundreds of research projects can be found in a powerful database with an underpinned keyword search in the Premium Resources section. Register for free and gain insights into the potential of Nanoscribe’s 3D Microfabrication technology for innovative applications and fundamental innovations in many areas.

Video information

Microscopic top view of the heart-on-a-chip platform with eight cell attachment sites loaded with cardiac tissue. The tissue aligns with the printed microstructures and synchronizes its spontaneous contractions with a stimulated beat. Video: M. Çağatay Karakan, Boston University