The most prominent example of X-ray imaging technology is radiography for medical diagnostics. This technology enables the non-invasive analysis of tissues such as bones, organs and other body tissues. But not only in the medical field X-ray technologies offer powerful diagnostic tools. Due to the deep penetration of X-rays into materials, X-ray microscopes can help to investigate in detail the inner structure of objects that are opaque for visible light. Furthermore, the small wavelength of X-rays allows for high resolution images of smallest samples down to single viruses on the nanometer scale.

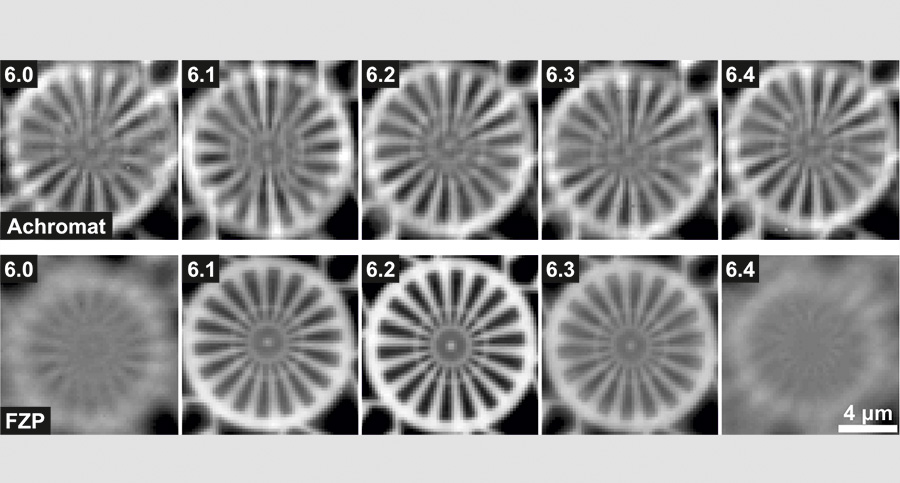

Currently, X-ray-based microscopes are restricted to narrow-bandwidth radiation sources since the refractive and diffractive optics in place suffer from inherent chromatic aberration resulting in a different focal position for different X-ray energies.

Two-Photon Polymerization for high-performance X-ray achromats

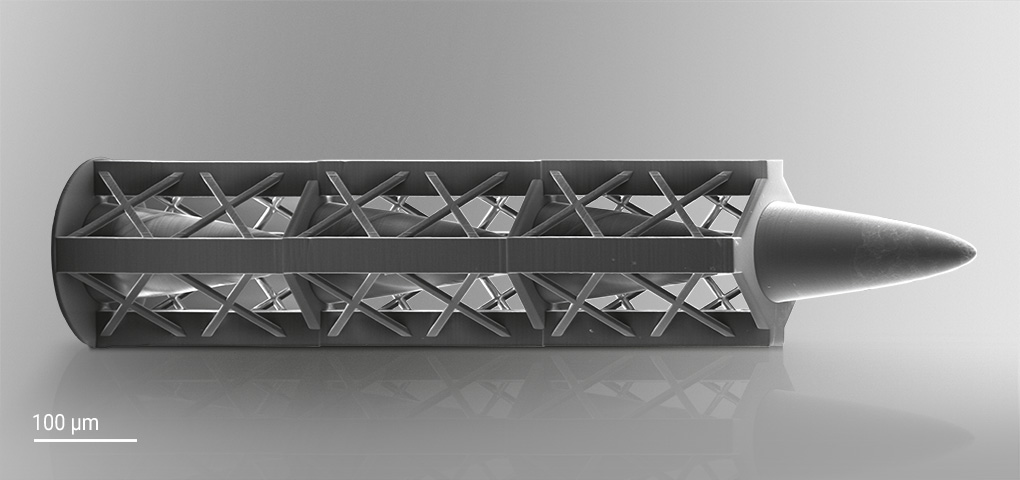

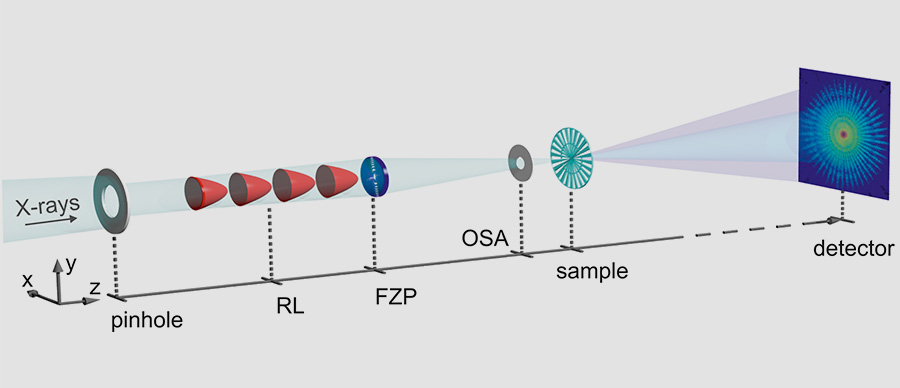

Scientists from the Paul Scherrer Institute in Villigen and experts of the company XRnanotech addressed this issue in a joint study and developed the first X-ray achromat with the help of Nanoscribe’s 3D printing technology. This achromatic optics consists of two elements, a Fresnel zone plate (FZP) fabricated by electron-beam lithography and a 3D-printed refractive microlens stack consisting of four combined parabolic microlenses. The 2PP-fabricated microlens stack is the centerpiece of the development and enables scanning transmission X-ray microscopy (STXM) free of chromatic aberration over a wide range of X-ray energies.

High aspect ratio compound refractive microoptics

The idea behind chromatic aberration correction can be traced back to the 18th century. Stacking a focusing lens made of crown glass and a defocusing lens made of flint glass resulted in an achromatic doublet that corrects the chromatic aberration of visible light due to the different dispersion characteristics of the two materials. The research team had to overcome some challenges to transfer this concept to the X-ray regime. For high-energy X-rays, the dispersion difference between materials is negligible and consequently, the doublet lens concept cannot be applied directly to X-ray achromats.

Instead, the researchers exploited the different focusing properties of diffractive and refractive lenses. While the focal length of refractive lenses scales with the second power of the energy, diffractive optics exhibit linear dependence of the focal length on the energy. This makes it possible to cancel out the chromatic aberration of a focusing diffractive FZP by combining it with a defocusing refractive lens.

3D-printed microlens stack

Fabricating a suitable refractive lens for the X-ray achromat represented the biggest challenge to the scientists because, unlike visible light, X-rays do not refract easily and the focal lengths of refractive macroscale lenses become impractically long.