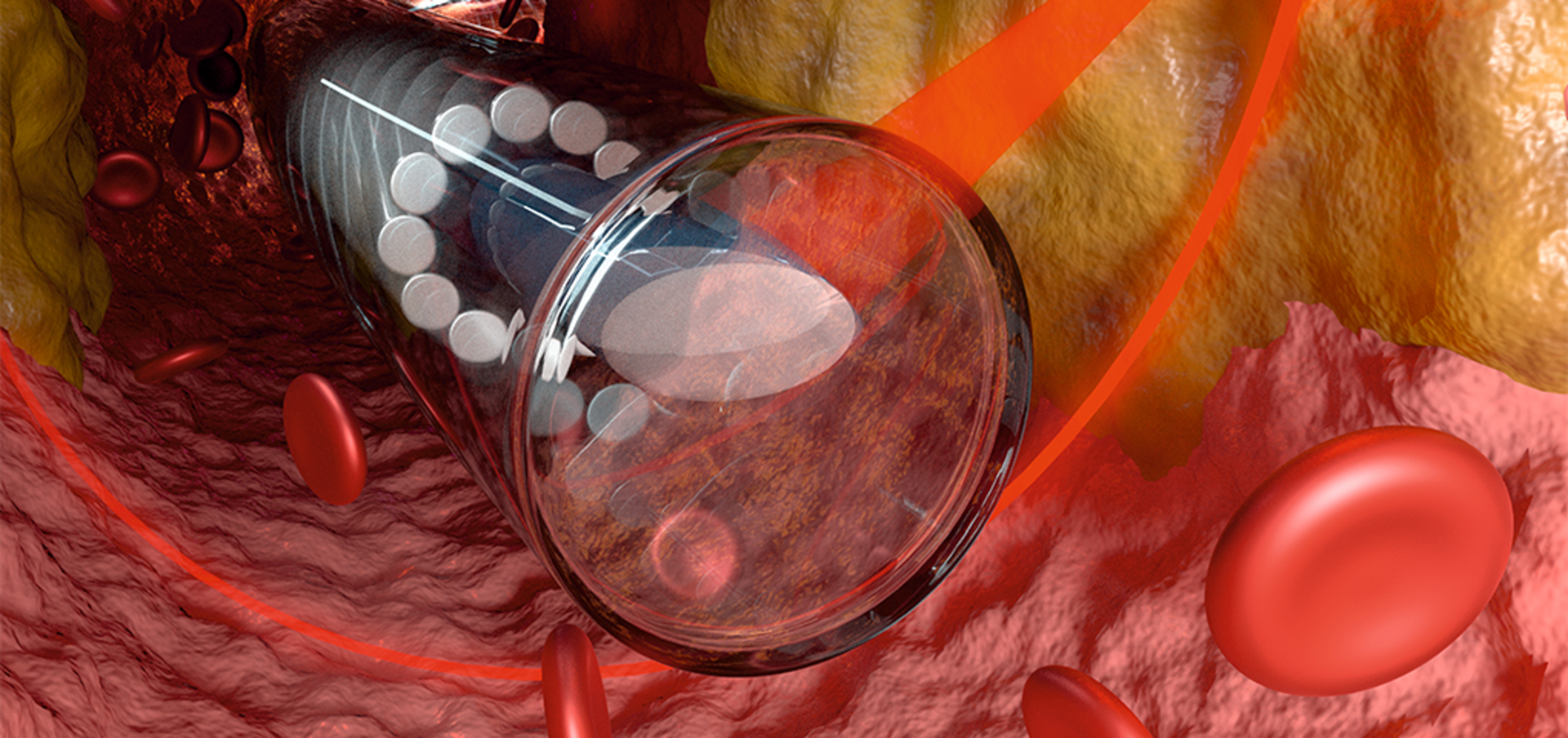

Endoscopes are used to examine inside the body, for example, coloscopy allows doctors to examine the intestines and gastroscopy the stomach. However, such endoscopes are often too large to go inside blood vessels. Fiber optic technology can be used to create probes small enough to be safely inserted inside blood vessels, with a diameter of only a few hundred microns. The challenge is still to fabricate very fine, freeform and powerful imaging optics on the tip of the fiber to take high-quality images from inside the vessels.

To investigate the feasibility of such microoptics, an international team from the University of Stuttgart, together with the University of Adelaide, the Royal Adelaide Hospital, SAHMRI Institute in Adelaide and Monash Cardiovascular Research Center in Melbourne worked together on the design, fabrication and testing of the world’s smallest endoscope. Using a 3D-printed microoptical endoscope, the doctors examined the inside of blood vessels of mice and humans.

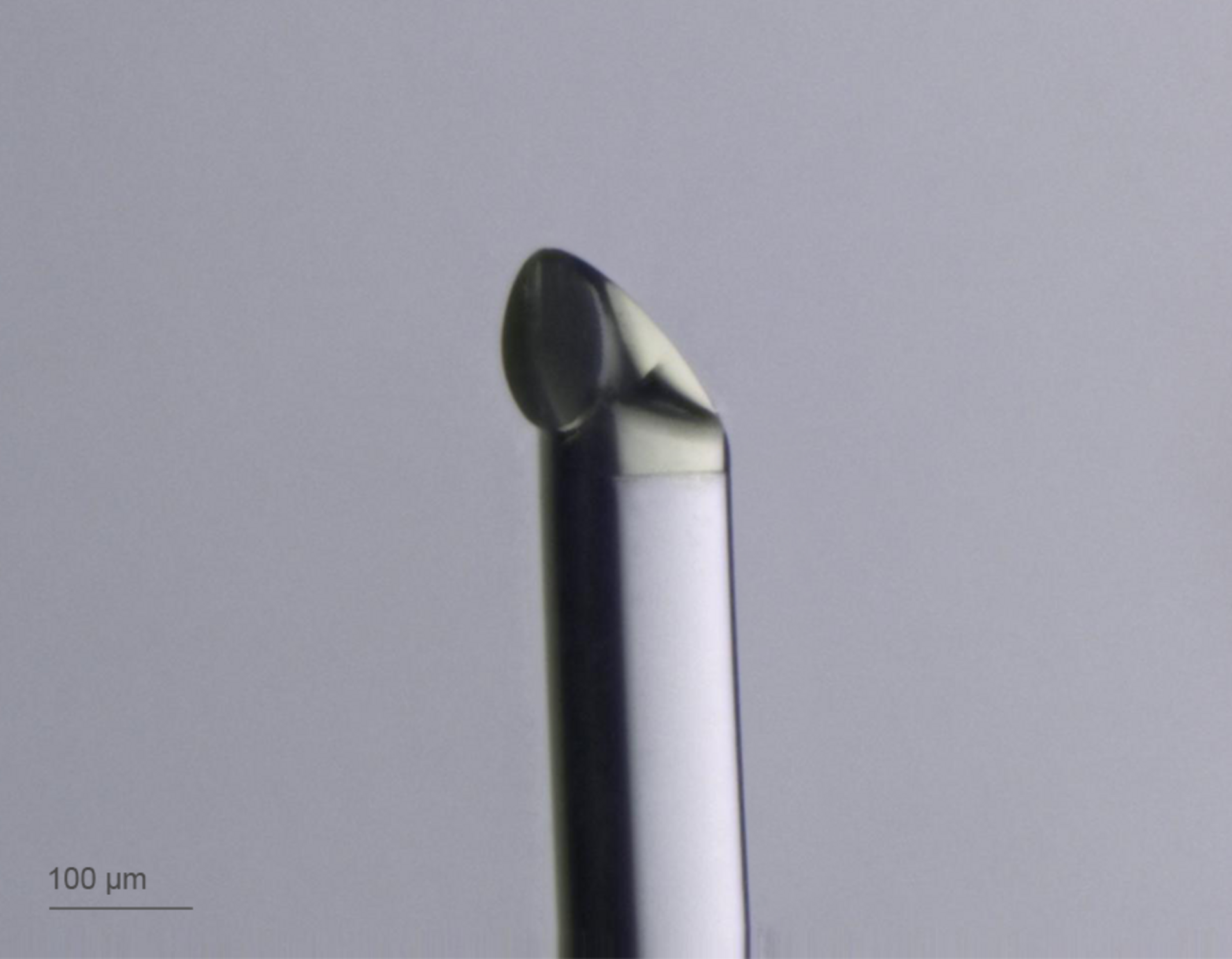

3D Microfabrication of freeform microoptics on a fiber tip

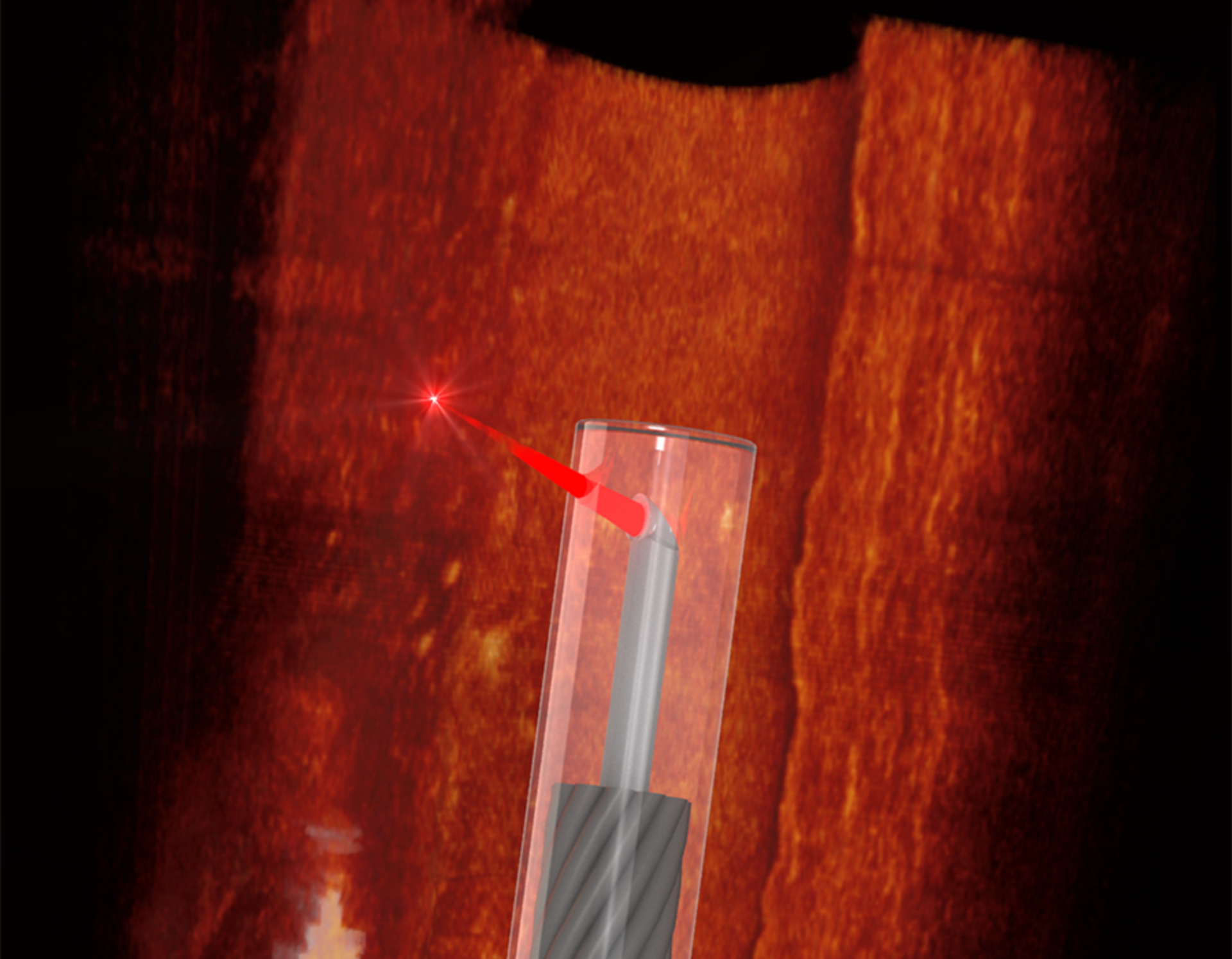

The endoscope uses optical coherence tomography (OCT). This imaging technology utilizes a light beam with a broad spectrum of colors that penetrates the tissue. The analysis of the reflected light enables exact depth imaging of tissue with high spatial resolution. The microoptics needed for this type of endoscopy deflects a light beam from inside the glass fiber sideways to the inside vessel wall. The optics detects the shape of the vessel and depth composition and sends their reflection back into the fiber, to obtain a high-resolution image with a minimally invasive device.

To this end, the beam shaping microoptics has an intricate three-dimensional shape, consisting of a planar surface directed to the catheter sheath and a freeform mirror for total internal reflection to redirect and focus the beam. Moreover, the microoptics also corrects optical aberrations in the transparent polymer catheter sheath. Using Nanoscribe’s 3D Microfabrication technology, the scientists were able to 3D-print this unique design directly onto the tip of the fiber. The imaging probe can rotate and move linearly inside the catheter sheath to take a 3D image of the vessel.

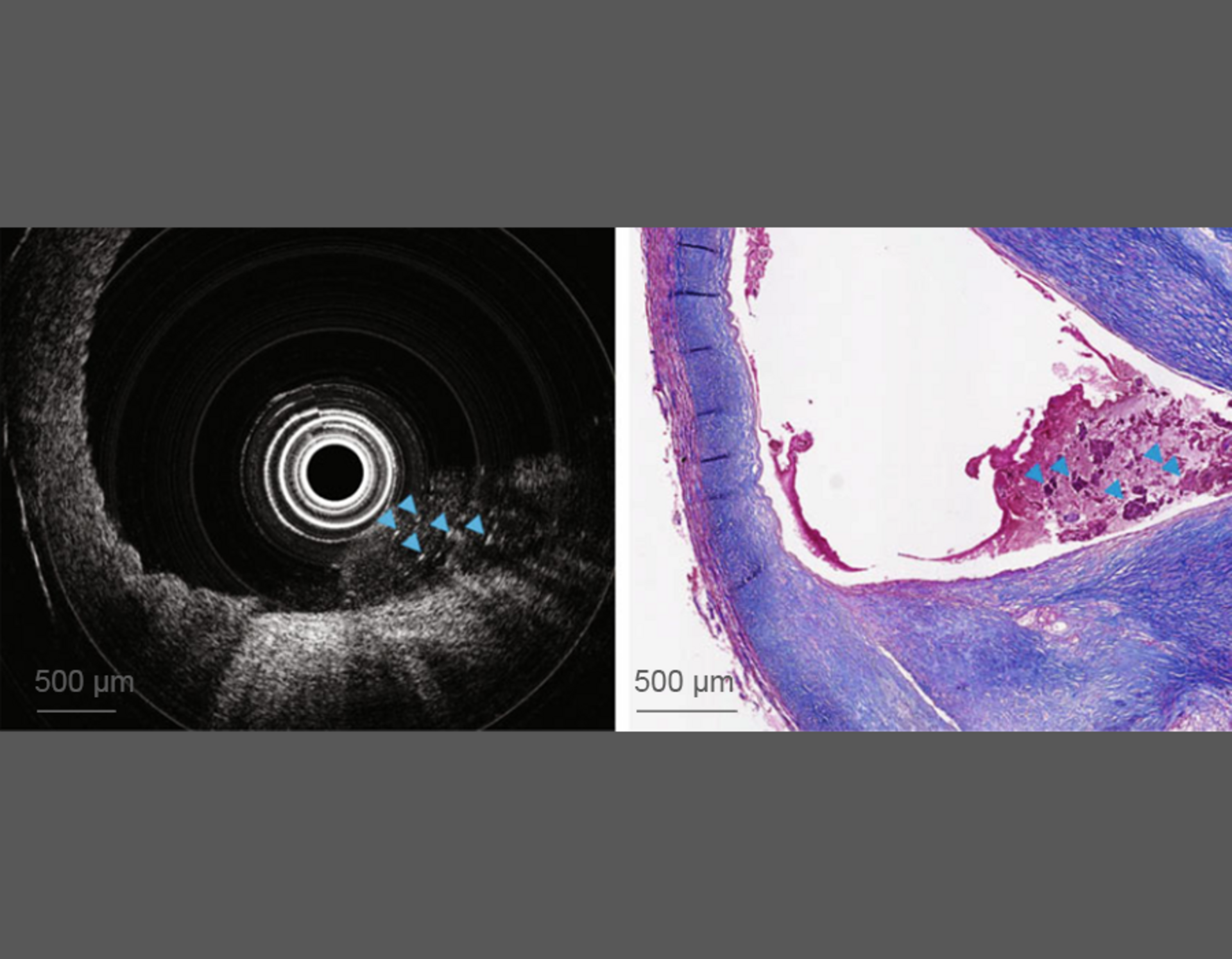

Detecting plaques and cholesterol crystals by ultrathin OCT system

Using the miniature microoptical OCT endoscope, the scientists detected plaques and cholesterol crystals in human carotid arteries and in the aortas of mice that are used for research in heart disease. Comparison with stained microscope images of the sliced tissue confirmed the ability of the probe to obtain accurate, high quality images. This tiny imaging probe provides a powerful new tool to help medical researchers understand the causes and treatments for heart disease.

Read the open access Light: Science & Applications publication here: Ultrathin monolithic 3D printed optical coherence tomography endoscopy for preclinical and clinical use