The invention of antibiotics is certainly one of the great milestones of modern medicine and has relieved many people’s fear of infectious disease such as tuberculosis or pneumonia. However, the fight against bacteria infections is once again coming into focus of experts in medicine and biology. Due to the high use or even misuse of antibiotics, bacteria become increasingly resistant to their treatment and even minor infections can once again become life-threatening. To counteract this, antibiotics should only be administered when necessary and in accordance with the respective disease pattern.

In situ bacteria characterization by fiber-optics SERS probe

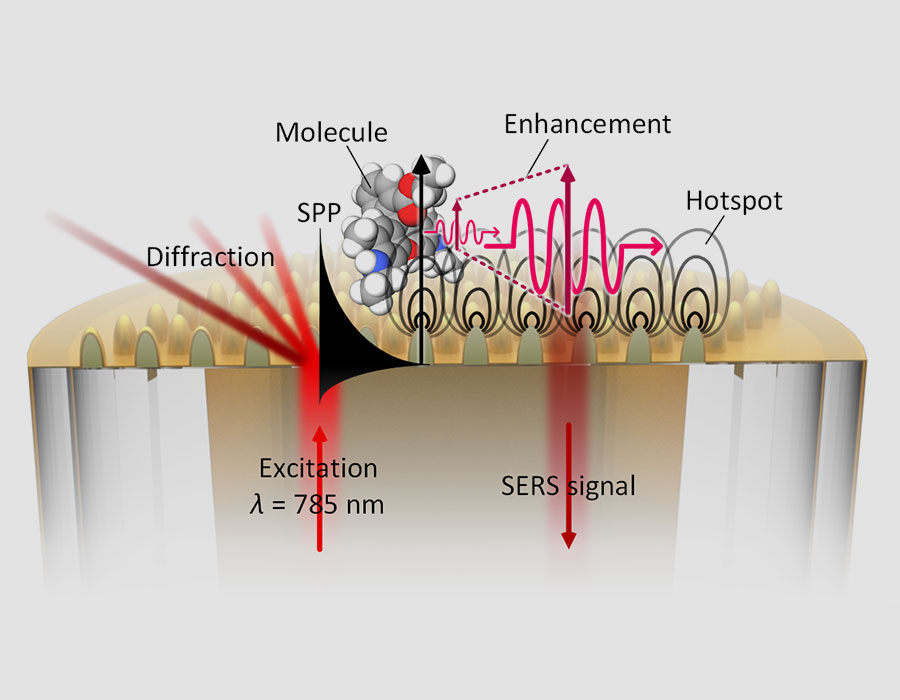

Scientists at Imperial College London are contributing to this global challenge by developing a fiber optical sensor for the label-free detection and characterization of bacteria. This miniaturized fiber optic sensor, based on surface-enhanced Raman spectroscopy (SERS), is the first of its kind and can potentially be integrated into medical endoscopes for in situ analysis of inflamed tissue. Raman spectroscopy is a powerful analytical technique for organic and biological samples, allowing the characterization of samples such as bacteria based on their individual spectral fingerprint. The inherently weak nature of Raman scattering can be enhanced by metallized micro- and nanostructured surfaces, creating signal hotspots that interact with the sample. In their study, the scientists 3D printed these micro- and nanostructures on the facet of optical fibers using Two-Photon Polymerization (2PP) and then coated them with a thin layer of gold. For SERS measurements, a laser light is coupled into the optical fiber and excites signal hotspots on the nanostructured surface of the fiber probe. In interaction with the analyte, the SERS signal is generated and collected by the optical fiber.

Rapid prototyping with short design iteration cycles

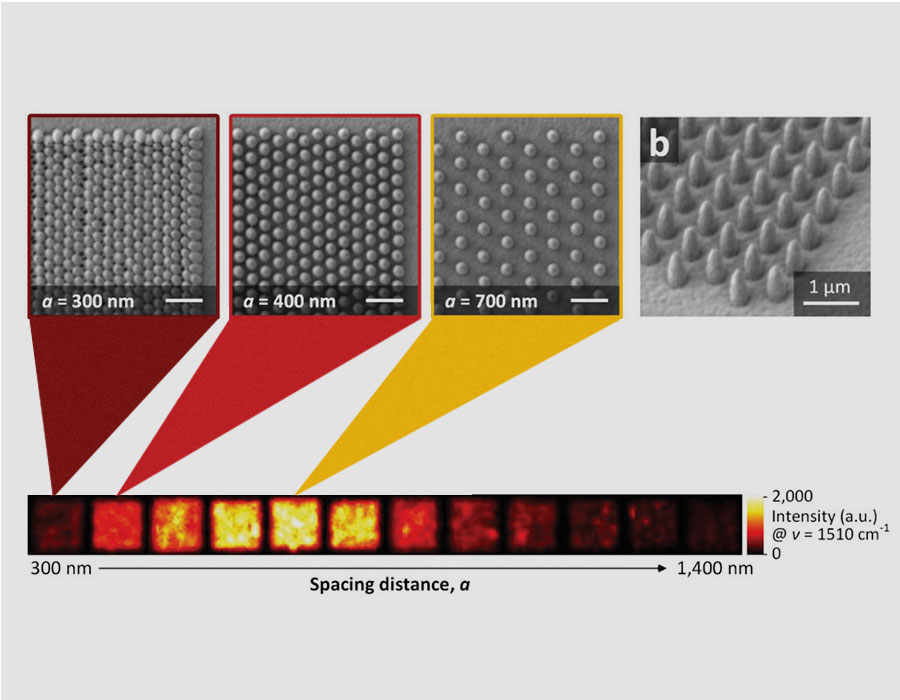

In a first design study, the scientists analyzed the SERS effect of various micro- and nanopatterns printed on a planar glass substrate using Nanoscibe’s 2PP technology. A hexagonally arranged single-voxel array proved here to be the most efficient sample. With rapid design iterations, the researchers further optimized the spacing distance between the individual voxels of the array and fabricated samples with impressively small spacing distances of only 400 nanometers, which is challenging but in fact still feasible with 2PP-based microfabrication.

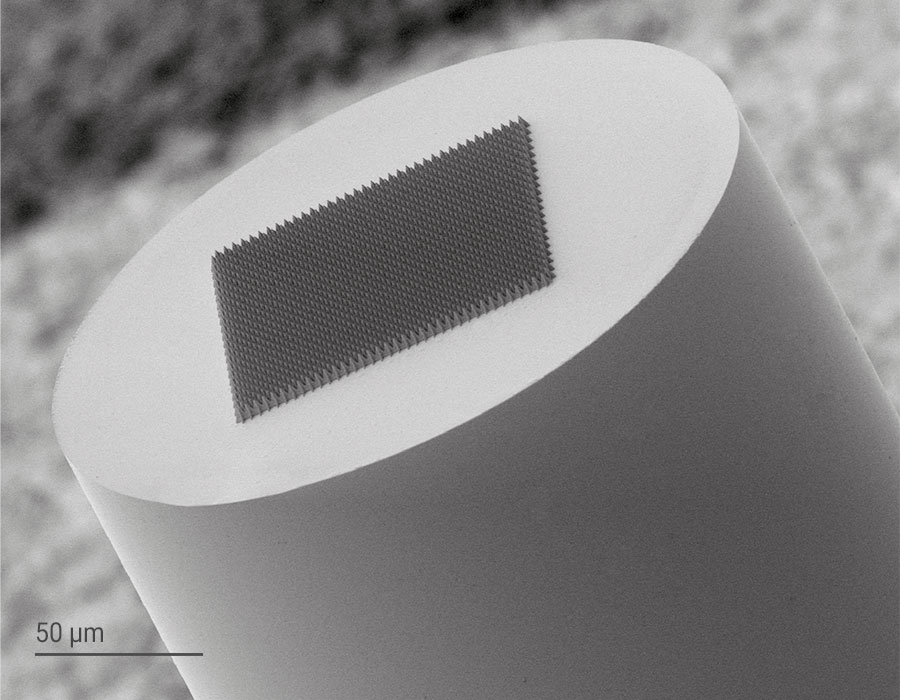

A second design that proved to be efficient for SERS measurements was a microspike array that guides and concentrates the signal hotspots at the apexes. Specifically printed on fibers, this design showed increased mechanical stability compared to the single voxel array and was further investigated for the detection of E. coli bacteria.

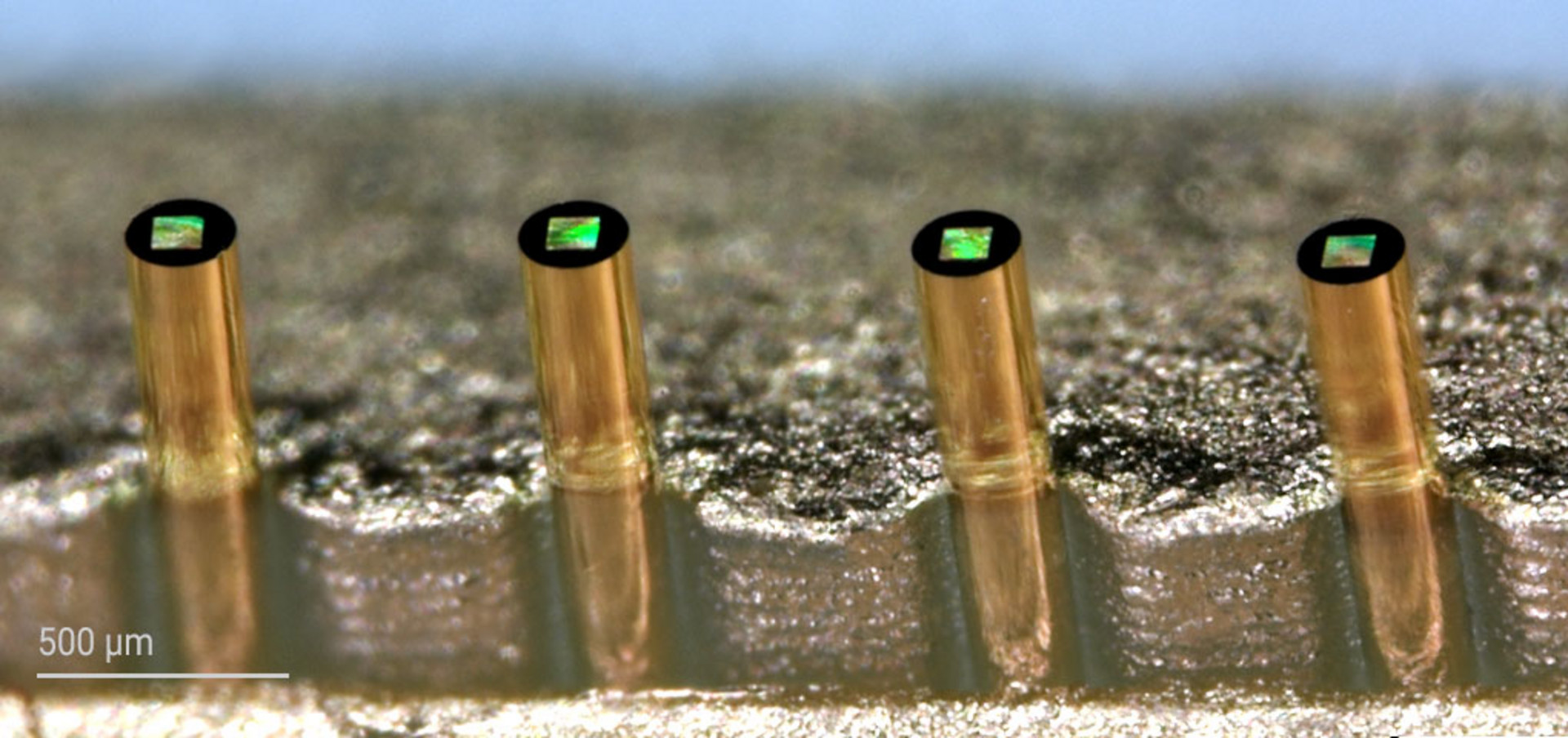

For the final fiber-optic SERS probe, the researchers printed the optimized microstructures directly onto the facet of the fiber and demonstrated its analytical capabilities by detecting unlabeled E.-coli bacteria.

Nanoscribe’s solution for tilt compensated and aligned on-fiber printing

For the on-fiber printed SERS probe, the researchers had to overcome several fabrication challenges. First, they designed a custom fiber holder that allows to print on the facet of a fiber. Then, the printed object must be perfectly aligned to the core of the optical fiber to excite the microfabricated Raman hotspots. A remaining challenge, especially for filigree structures such as the single voxel array, is the compensation of a potentially tilted substrate surface. The tilted substrate surface of the optical fiber resulted in a poor yield of the SERS active microstructures.

To drive innovations in photonics and applications of medical instrumentations and optical sensing, such as the intriguing fiber optical SERS probe, Nanoscribe recently introduced its latest 3D printer Quantum X align. With its proprietary on-fiber print set and tilt correction in all spatial directions, the new 3D printer may already provide the answer to the challenges of the on-fiber printed SERS probes and paves the way for further improvements and new innovations.

Read the scientific publication here: Fiber-Optic SERS Probes Fabricated Using Two-Photon Polymerization For Rapid Detection of Bacteria