Researchers around the globe are developing vaccines to safely and efficiently prevent the spread of a variety of diseases, such as COVID-19 caused by the SARS-CoV-2 coronavirus. Vaccines can help fight infectious diseases by stimulating our immune system. However, current routine vaccinations use painful hypodermic needle-based injections that deliver antigens into muscle or subcutaneous tissues instead of immunologically rich skin microenvironment. As such, prevailing vaccination strategies result in low immunogenicity and poor patient compliance, leading to a lower rate of global immunization coverage.

3D Microfabrication for cutaneous vaccine delivery systems

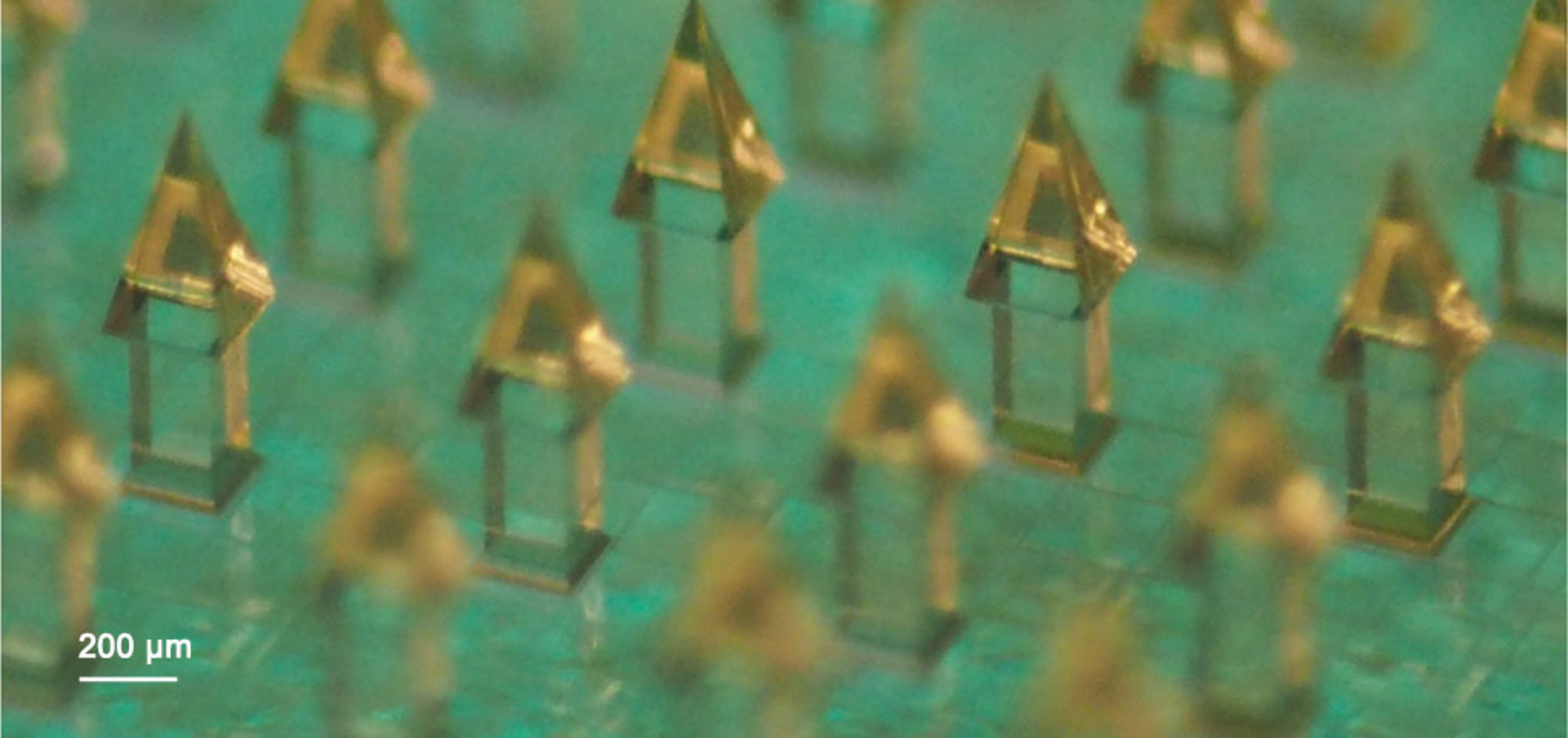

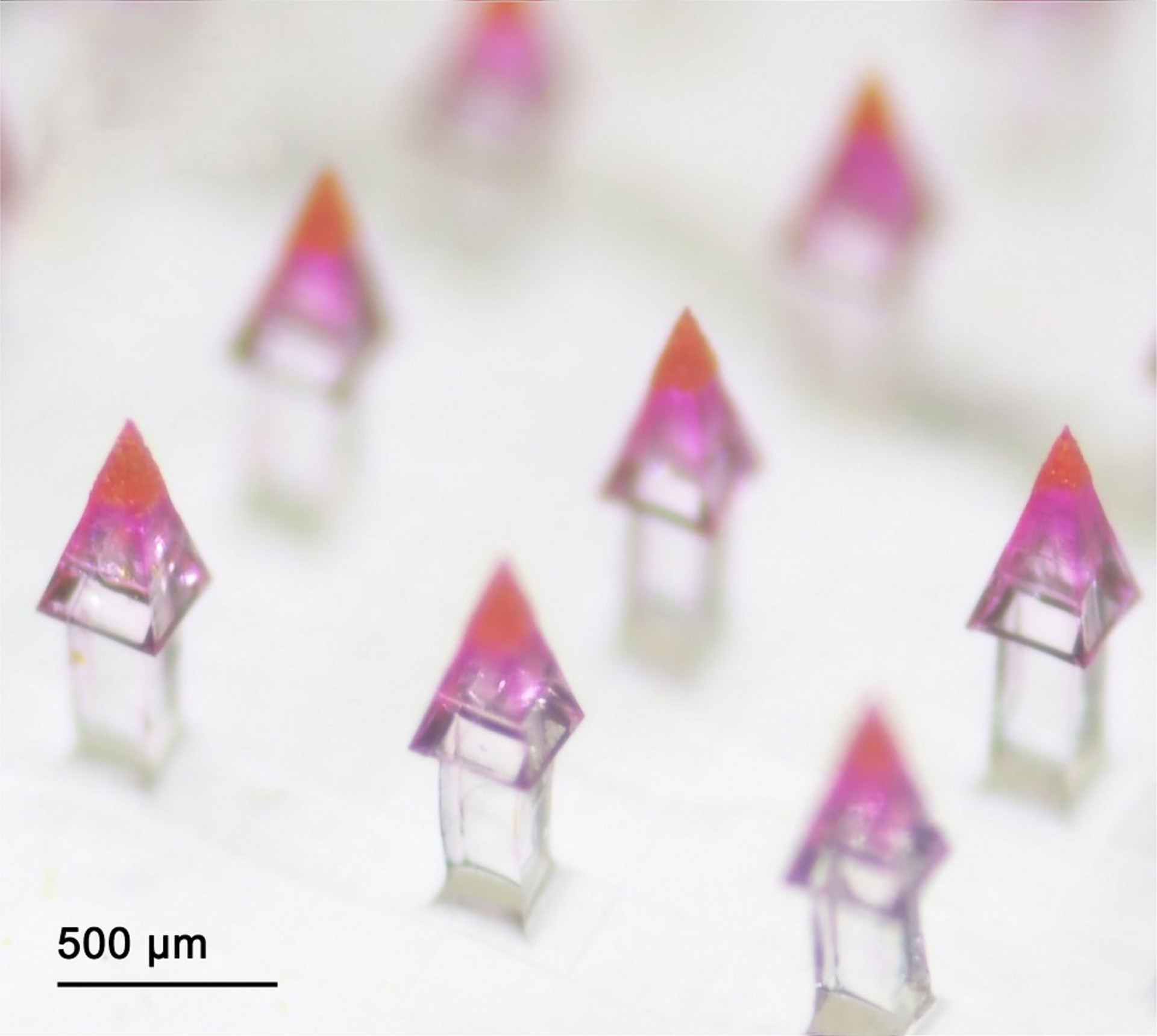

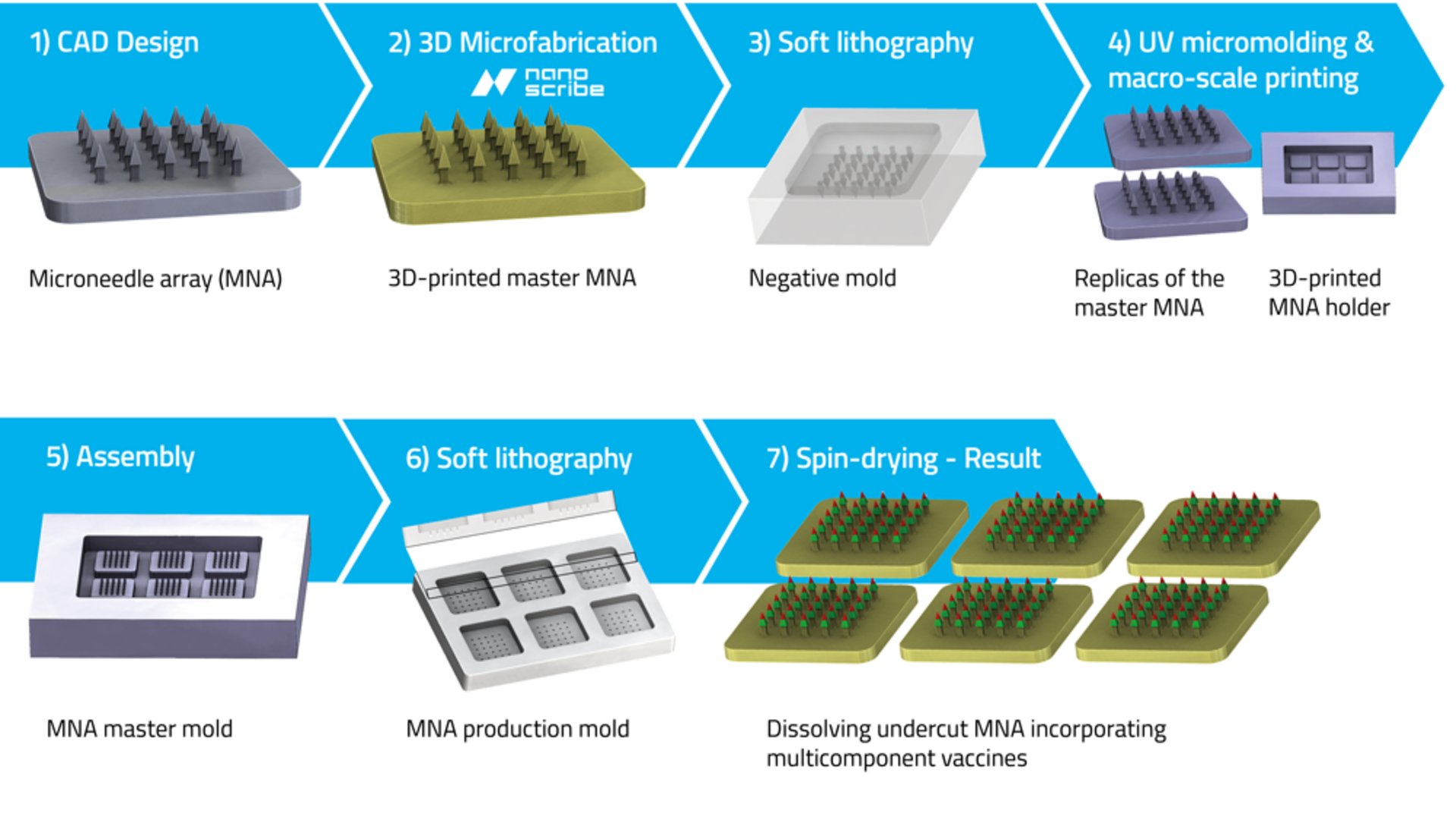

To tackle this issue, an interdisciplinary team of scientists and engineers from the University of Pittsburgh’s Department of Dermatology, Department of Bioengineering, Clinical and Translational Science Institute, McGowan Institute for Regenerative Medicine, and the UPMC Hillman Cancer Center develop dissolving microneedle arrays for cutaneous vaccine delivery systems. The researchers use a Nanoscribe Photonic Professional system at the University’s Nanoscale Fabrication and Characterization Facility to print prototypes and masters of microneedle arrays to enable fabrication of dissolving microneedle arrays. These drug delivery systems aim to facilitate diverse immunization strategies.

The researchers tell that when designing microneedle arrays for cutaneous drug or vaccine delivery, Nanoscribe’s 3D printer allows them to think freely without worrying about the design complexities, while also offering great ease of use. Accordingly, they report that Nanoscribe’s systems not only attract engineers, but also impress medical scientists who do not necessarily have microfabrication expertise, and look for simple ways to realize their ideas. For both disciplines, 3D microfabrication has become a key technology to achieve optimization of cutaneous drug or vaccine delivery systems.

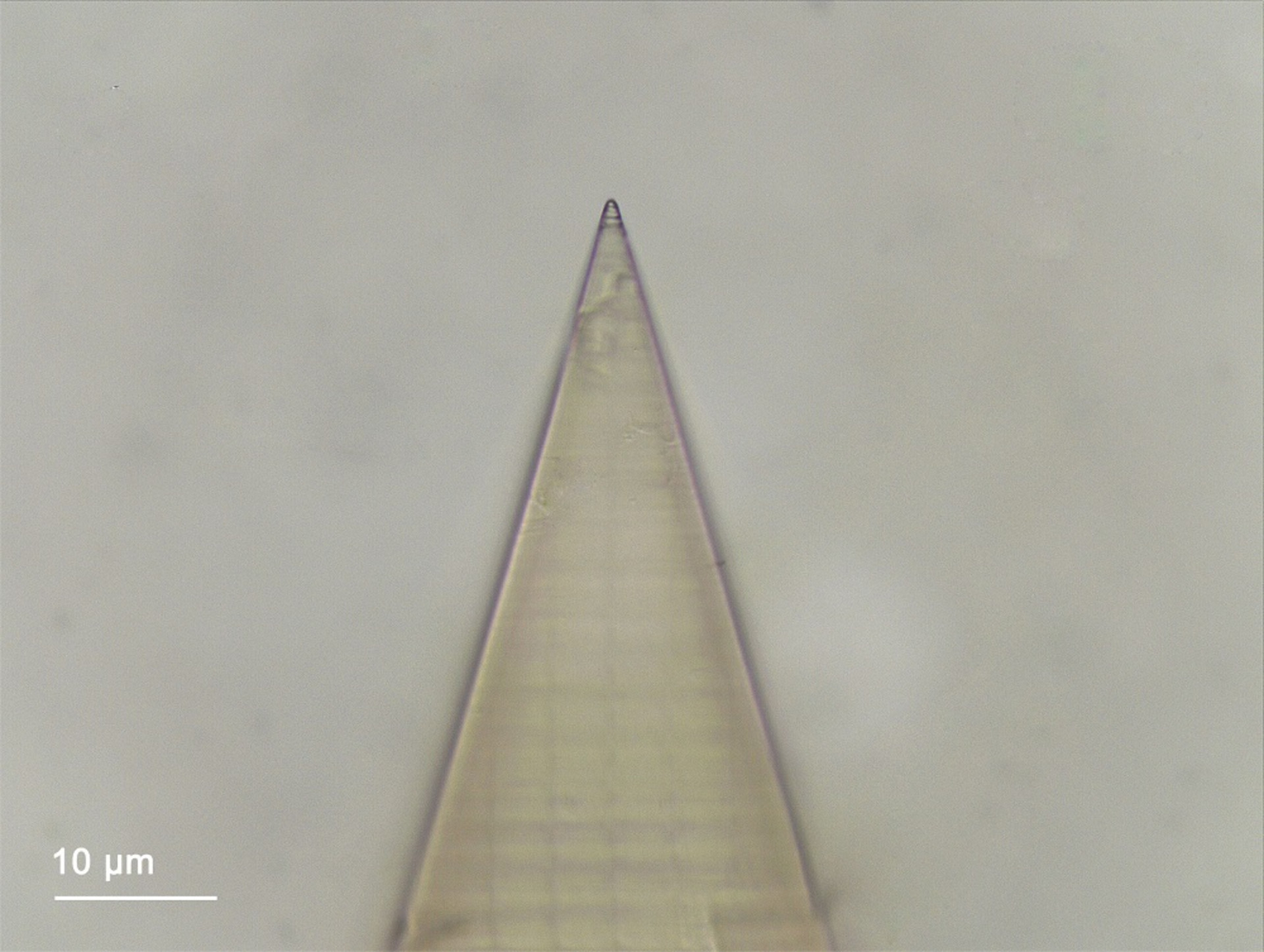

To ensure successful skin delivery, their microneedle design includes sharp tips, rounded bases, and undercut features. The tip radii of the microneedles are a key player in tissue insertion forces. Intuitively, the sharper the needles are, the better their skin penetration performance is. Nanoscribe enables the fabrication of sharp microneedles with nanoscale resolution. Further, the fillet at the base of the needles is critical for improving the strength performance of the microneedles during application. Different design parameters can be optimized with microscale additive manufacturing without any complex requirements.