The strong interaction of light with gases, liquids or biological agents in integrated photonic devices enables novel methods and mobile applications in environmental monitoring and biosensors. Advanced optical sensing elements are needed to enhance strong light-matter interaction. With this goal in mind, a team of scientists from the Leibniz Institute of Photonic Technology, the Ludwig-Maximilians-Universität Munich, the Imperial College London and the Otto Schott Institute of Materials Research of the Friedrich Schiller University of Jena develops a new waveguide concept of a 3D light cage. The waveguide traps light behind microscopic bars and guides it over distances of many millimeters by means of the photonic band gap effect. The open design of the light cage is advantageous for strong interactions between light and matter, such as liquids or gas molecules.

3D Microfabrication of photonic waveguides

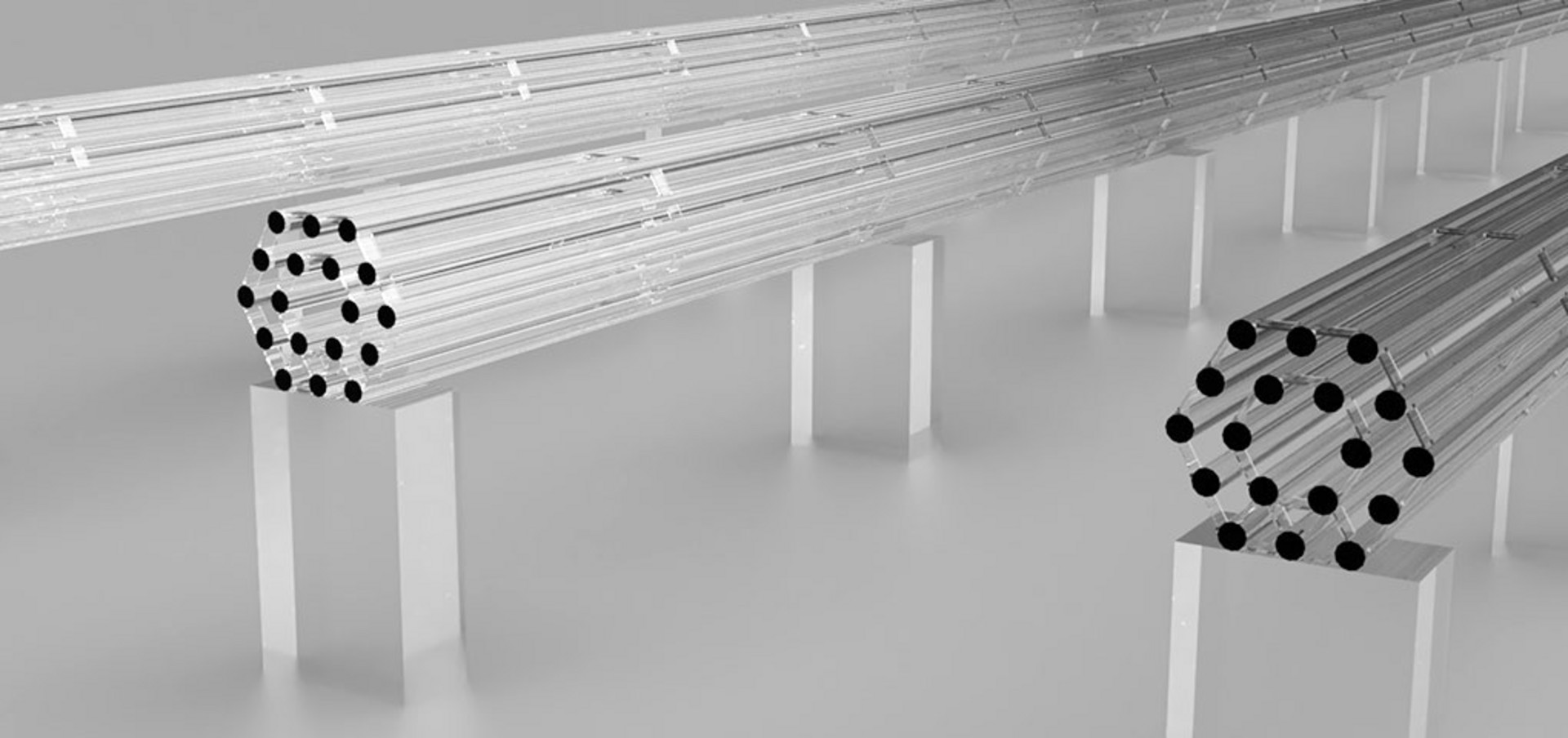

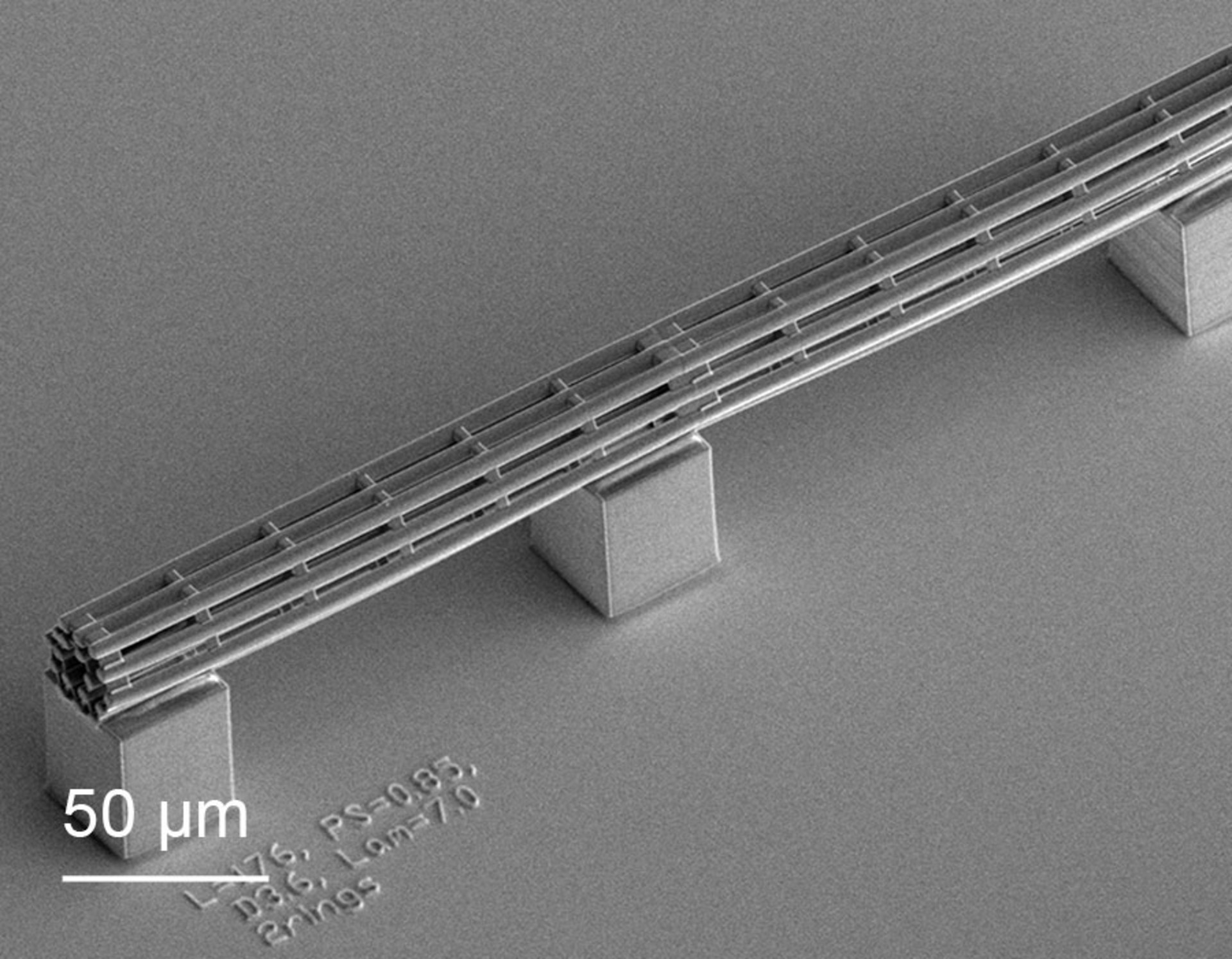

To fabricate this challenging microscopic structure, the scientists print the dual-ring light cages directly on a silicon chip by means of Nanoscribe’s 3D Microfabrication technology. The complex architecture consists of two rings with strands arranged hexagonally around a hollow core where the light is guided. The extremely fine strands have a diameter of 3.6 µm, a pitch between the strands of 7 µm and a length of 5 millimeters, reaching a high aspect ratio of more than 1,000.

The 3D microstructure design allows lateral access to the core regions of the waveguide through the open spaces between the strands. Consequently, molecules can enter the hollow core from the side and interact with the light in the core area. Performance tests demonstrate efficient waveguiding through the 3D light cage. Moreover, chip integration makes the light cage concept attractive for a number of fields such as bioanalytics or quantum technology. According to the above-mentioned research team, the length of the waveguide has reached up to 3 cm, yielding an aspect ratio higher than 8,000.