Microstructured optical fiber tapers

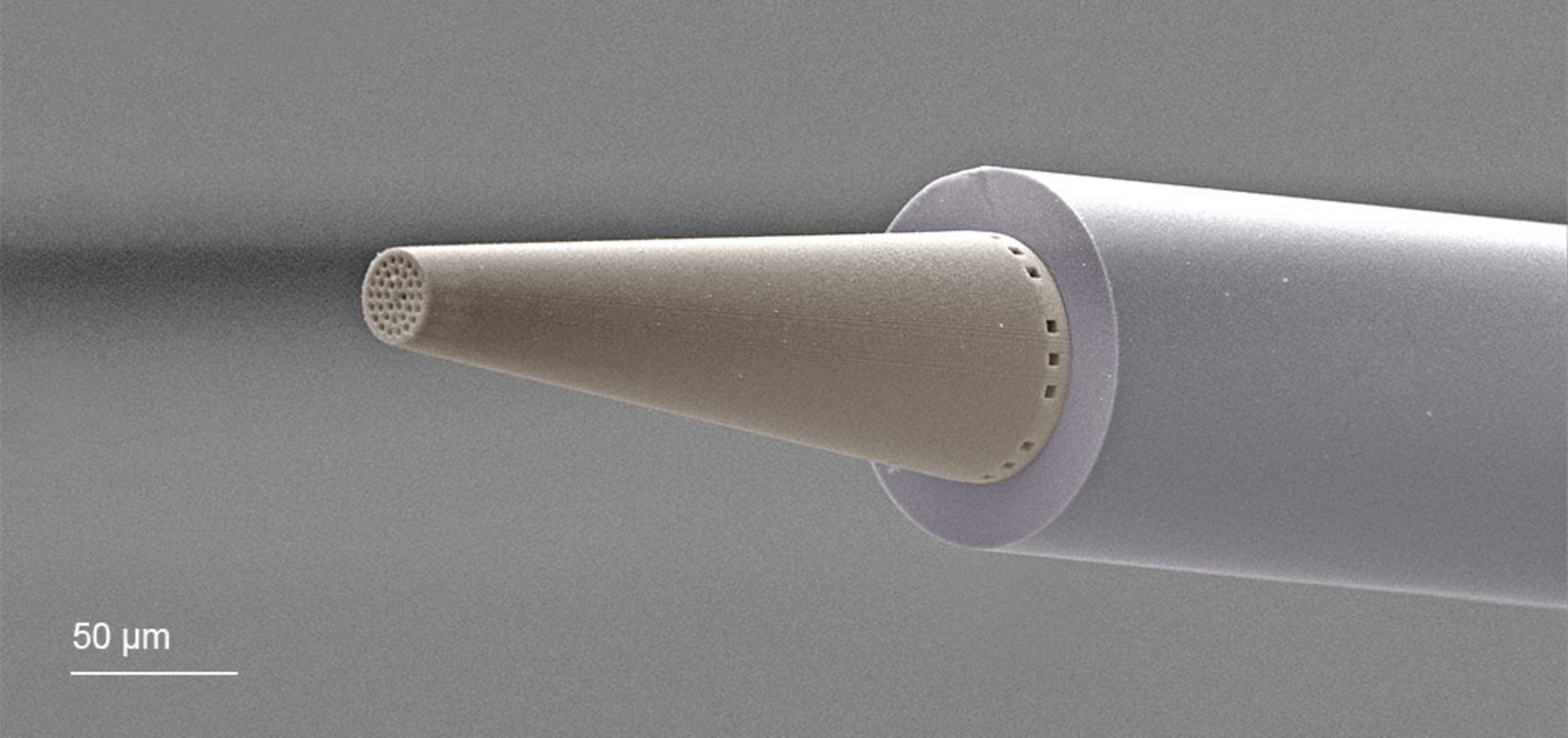

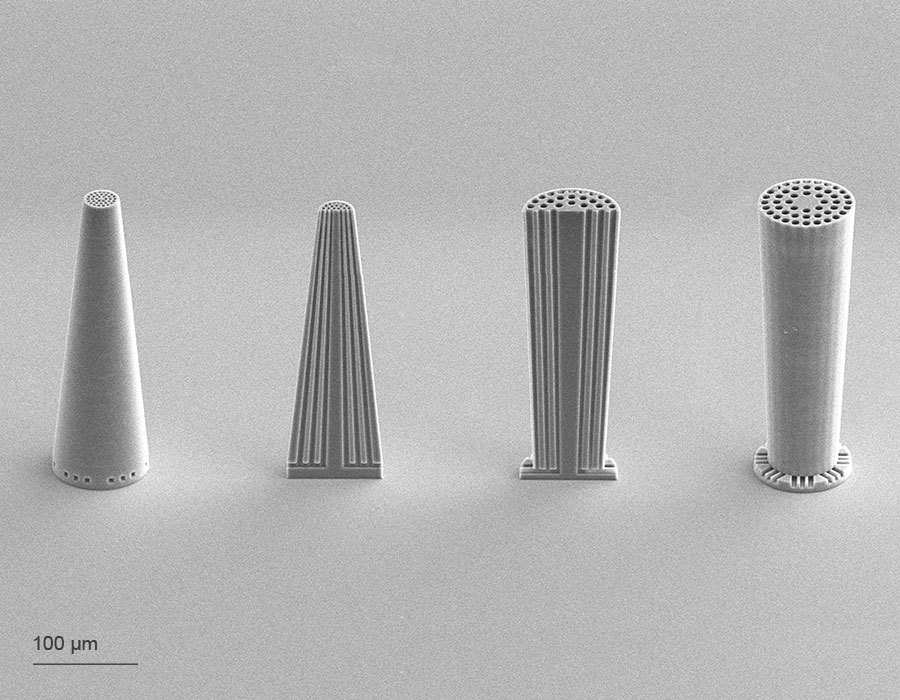

For further improvements the scientists from Brussels designed these mode field adjusting tapers as microstructured optical fibers (MOFs). These fascinating waveguides are structures made of a single material with a lattice of air holes running along the length of the fiber. By varying the design geometries of these air holes, the light propagation characteristics of MOFs can be tuned to parameters such as polarization, modal dispersion, birefringence and nonlinearity. The size and shape of the mode field can also be adjusted with these elements, and that’s exactly what the researchers investigated in their work. They printed MOF structures directly on the end of an optical fiber to reduce the mode field (down-taper) and MOFs to increase the mode field (up-tapers). Thanks to the precision of 2PP-based 3D Microfabrication, the scientists optimized the distribution of the air holes on the printed tapers and achieved a highly efficient guidance of the adjusted optical modes.

The new MOF tapers could further improve the performance of the mode field adjusting tapers and bring photonics packaging one step closer to practical applications.

Photonics packaging for tomorrow’s innovation

With their mode field adjusting fiber tapers, the scientists from Belgium address an urgent need in the field of photonics to find solutions for low-loss light coupling and mode field adjustments for different optical systems. But the team is not the only ones actively seeking solutions to these issues. Nanoscribe is project partner of several innovation projects to develop novel technologies based on integrated photonics and photonics packaging solutions. The MiLiQuant project aims to produce alignment- and maintenance-free radiation sources for industrial applications. Furthermore, in the EU-funded photonic computing project PHOENICS the University of Münster (Germany) brings together world leaders in neuromorphic photonic computing to achieve energy-efficient petascale processing power with ultra-high bandwidth. The aim is to develop disruptive methods for implementing next-generation computing platforms for applications in artificial intelligence (AI).

Photonic integrated circuits (PIC) are miniaturized optical platforms that integrate multiple photonic functions with enormous potential for applications such as optical computing, data transmission and telecommunication, sensor technology in the medical field, and autonomous driving supported by LIDAR systems.

A challenge in the field of photonic integrated circuits is the efficient and robust coupling of light between two elements with different mode field geometries. Light is typically guided through standard single-mode fibers (SMF), and the core of these SMFs is about an order of magnitude larger than the waveguide on a photonic chip. It is comparable to filling a small glass bottle with a bucket of water. Without the help of a funnel, the bottle cannot be filled efficiently.

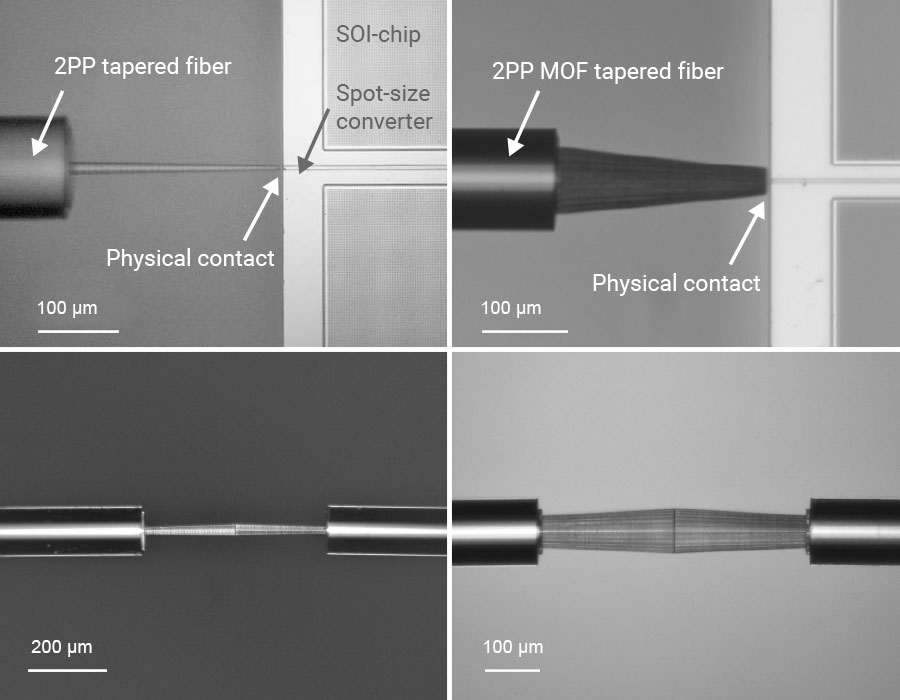

Scientists at the Brussels Photonics (B-PHOT) research group of the Vrije Universiteit Brussel are addressing this bottleneck in photonics with their research by 3D printing light-guiding funnels onto the flat end of an optical fiber using Two-Photon Polymerization (2PP). These funnels are tapered beams that adjust the mode field of the SMF to match the mode field of a waveguide on a photonic chip. In addition, the researchers invert these funnels and printed up-tapered beams that expand the mode field and help to relax the tight alignment tolerance of fiber-to-fiber connections.

High aspect ratio tapered fiber ends for precise mode field adjustments

In pre-studies, the scientists printed mode-field adjusting tapers as step-index light guiding beams using Nanoscribe’s 2PP technology. Printed on the flat end of SMFs, these up- and down-tapered beams are extensions of the fiber core. Over a length of more than 240 µm, these high aspect ratio structures adjust the mode field for desired application. For the fiber-to-chip connection, down-tapers are in physical contact with the photonic chip and transmit more than 90 % of the light intensity of the fundamental mode.

For up-tapered structures, the aim is to increase the mode field to relax the tight alignment tolerance of fiber-to-fiber connections. Here, the up-tapered structure increases the diameter towards the end, thus increasing the mode profile by a factor of 3, which significantly relaxes the alignment tolerance of fiber-to-fiber connections.