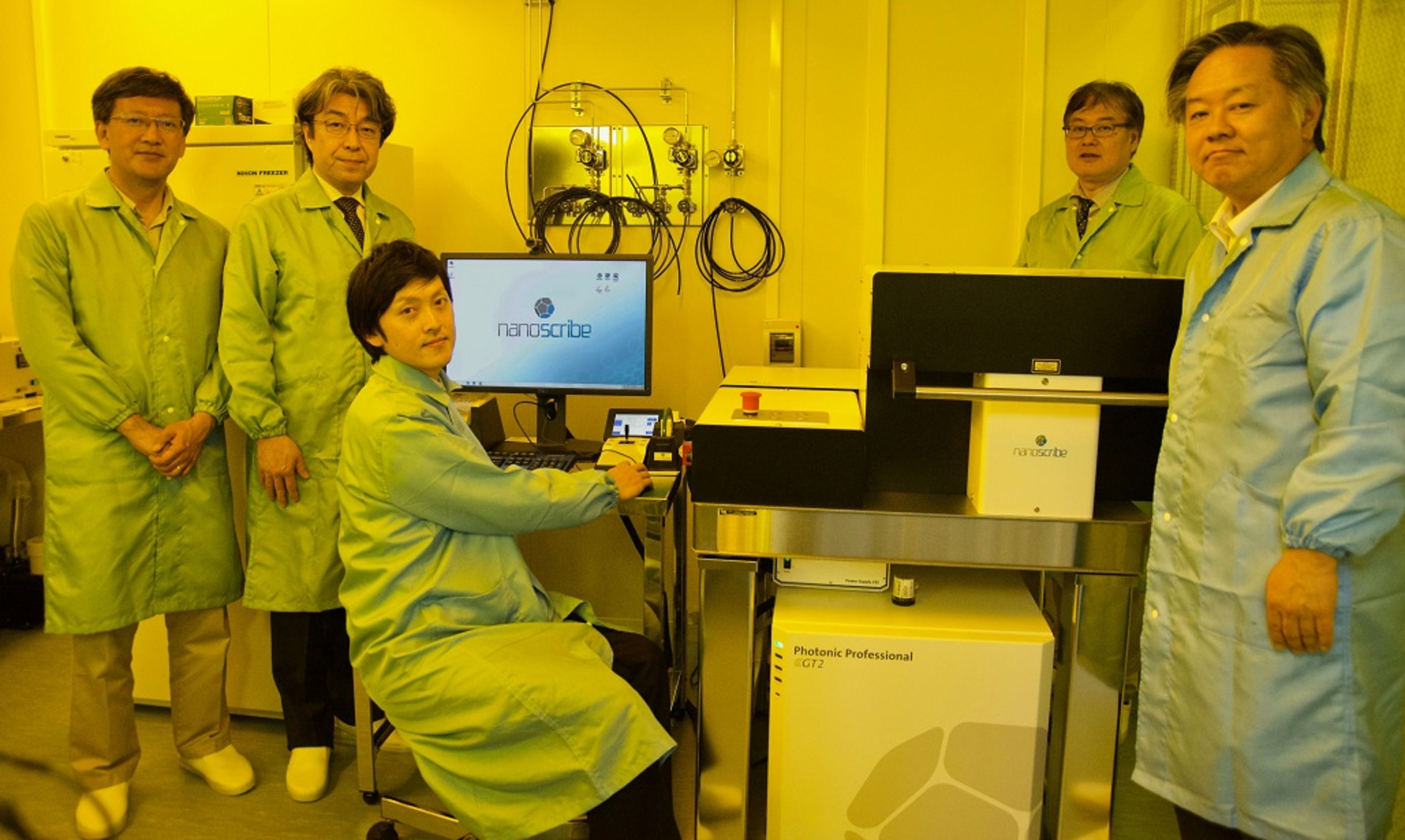

Back to the roots: KEIO University in Japan is now proud owner of a Photonic Professional GT2 system. The first installation of our latest 3D printer model could be considered a journey back to the starting point of the technology of two-photon polymerization (2PP). In 1997 Professor Satoshi Kawata provided the experimental proof of two-photon-polymerization in Japan. Nanoscribe utilizes 2PP’s strength to expose photoresists with extreme focus and highest resolution for the direct fabrication of nano- and microstructures that are otherwise impossible to produce.