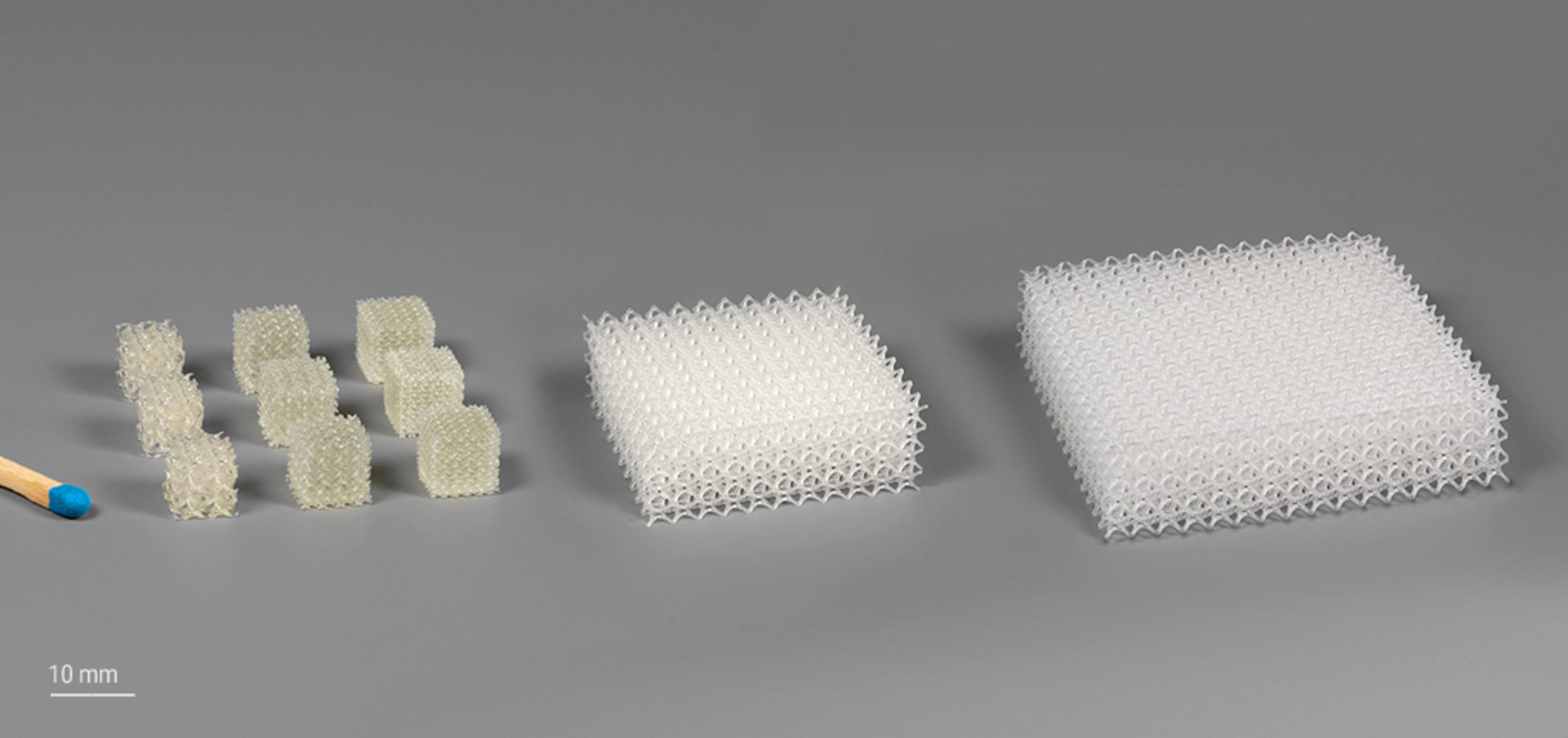

Thanks to the inherent advantages of Two-Photon Polymerization (2PP), this high-precision 3D printing technology is proven to be at least 100 times more precise than comparable technologies such as high-resolution SLA and DLP or projection micro-stereolithography (PµSL). Until now, 2PP was limited to object sizes of just a few millimeters. With the XLF Print Set, the high-precision 3D printing technology can now be seamlessly extended to centimeter-sized objects, with precision typically 2 to 5 times higher than comparable microfabrication technologies. In a single pass, objects up to 30 cubic centimeters can be produced.

High-precision 3D printing in the milli- and centimeter range

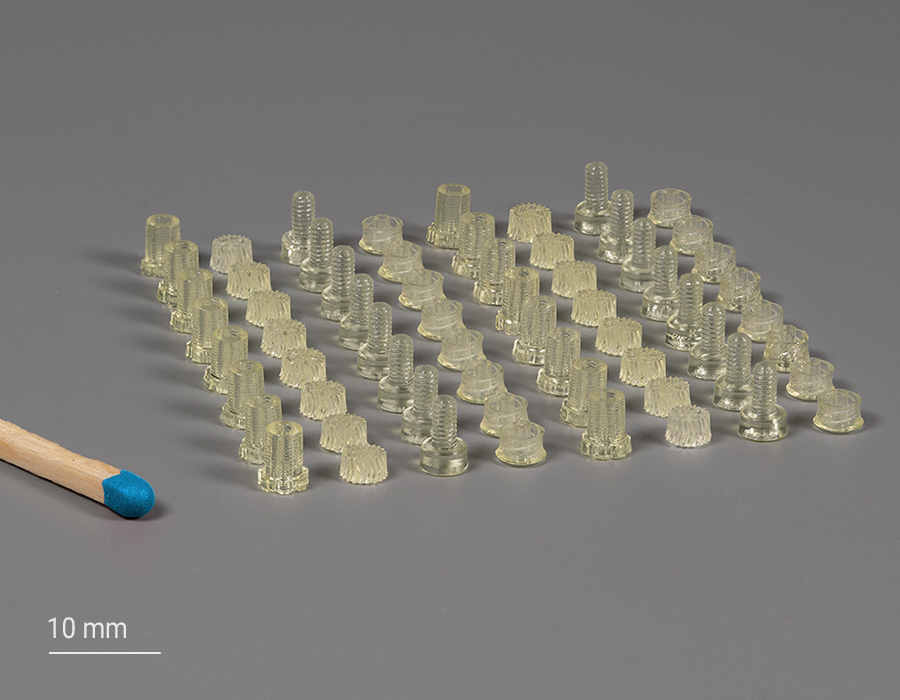

The XLF Print Set now makes it possible to print large parts with filigree features or even many millimeter-sized parts with complex structures or finest details. The Nanoscribe Quantum X shape is a superior laser-based 3D printing platform with straightforward processes and reliable workflows, so highly precise and accurate printing results are also achieved with the new XLF Print Set. It contains a new air objective with a magnification factor of 5x, resulting in an increased print field diameter of up to 3,200 µm and a comparatively large working distance of 18.5 mm. Combined with a high scanning speed, adjustable voxel sizes, and a highly sensitive photopolymer resin, the XLF Print Set provides a comprehensive solution for high-precision 3D printing in the milli- and centimeter range. It is therefore an attractive solution for prototyping and manufacturing, for example, mechanical parts such as millimeter-sized connectors and housings, microfluidic structures, and scaffolds for biomedical research.