Moreover, the versatile tool covers biomedical applications like customized microfluidic elements and microneedle arrays or microrobots for drug delivery. Connecting the micro to the macro world, 3D structures can be placed intuitively and with highest precision into microfluidic channels or wells by simply tapping on the machine’s touchscreen.

The power of bioconvergence for driving tissue engineering and biomedicine

The design freedom of Nanoscribe’s 3D printing technology is an important asset and accelerates design iteration cycles. With the easy-to-learn user interface and straightforward workflow, successful printing results are achieved even faster. Customers can choose of a wide range of biomaterials, bioresins, and biocompatible materials to suit their application. Combined with sterile consumables provided by e.g. BICO Group members MatTek and Advanced BioMatrix, everything is available that research labs, life science and pharmaceutical companies need to revolutionize tomorrow’s tissues engineering, cell cultivation and biomedical applications through the power of bioconvergence.

Companies and organizations interested in the Quantum X bio can find more information at nanoscribe.com and cellink.com.

About Nanoscribe

The medium-sized company develops and produces 3D printers and grayscale lithography systems as well as specially developed printing materials and application-specific solutions for various microfabrication applications. The specialist for additive manufacturing of high-precision structures and objects on the nano-, micro- and mesoscale was founded in 2007 as a spin-off of the Karlsruhe Institute of Technology (KIT) and has been part of the BICO Group since June 2021. More than 3,500 users and operators at top universities and innovative industrial companies worldwide benefit from the groundbreaking technology and application tailored solutions for 3D Microfabrication. Nanoscribe has created its strong market leading position through high quality engineering and agility to continuously develop its products to meet customers’ high expectations.

About CELLINK

CELLINK is creating the future of health as part of BICO, the world’s leading bio convergence company. When CELLINK released the first universal bioink in 2016, it democratized the cost of entry for researchers around the world and played a major role in turning the then up-and-coming field of 3D bioprinting into a thriving $1 billion industry. Today, the company’s best-in-class bioinks, bioprinters, software and services have been cited in over 700 publications and are trusted by more than 1,000 academic, pharmaceutical and industrial labs. At the forefront of the bioprinting industry, CELLINK aims to alleviate organ donor shortage with biofabricated transplantable organs and remains committed to reducing our dependence on animal testing and increasing efficiencies in drug development with more physiologically relevant bioprinted organ models. Visit cellink.com to learn more.

About BICO

Founded in 2016, BICO (formerly CELLINK) is the leading bio convergence company in the world. By combining different technologies, such as robotics, artificial intelligence, computer science, and 3D bioprinting with biology, we enable our customers to improve people's health and lives for the better.

With a focus on the application areas of bioprinting, multiomics, cell line development, and diagnostics, the company develops and markets innovative technologies that enable researchers in the life sciences to culture cells in 3D, perform high-throughput drug screening and print human tissues and organs for the medical, pharmaceutical, and cosmetic industries. We create the future of health.

The Group’s products are trusted by more than 2,000 laboratories, including all the top 20 pharmaceutical companies, are being used in more than 65 countries, and have been cited in more than 1,850 publications. BICO is listed on the Nasdaq the Stockholm under BICO, www.bico.com.

Captions

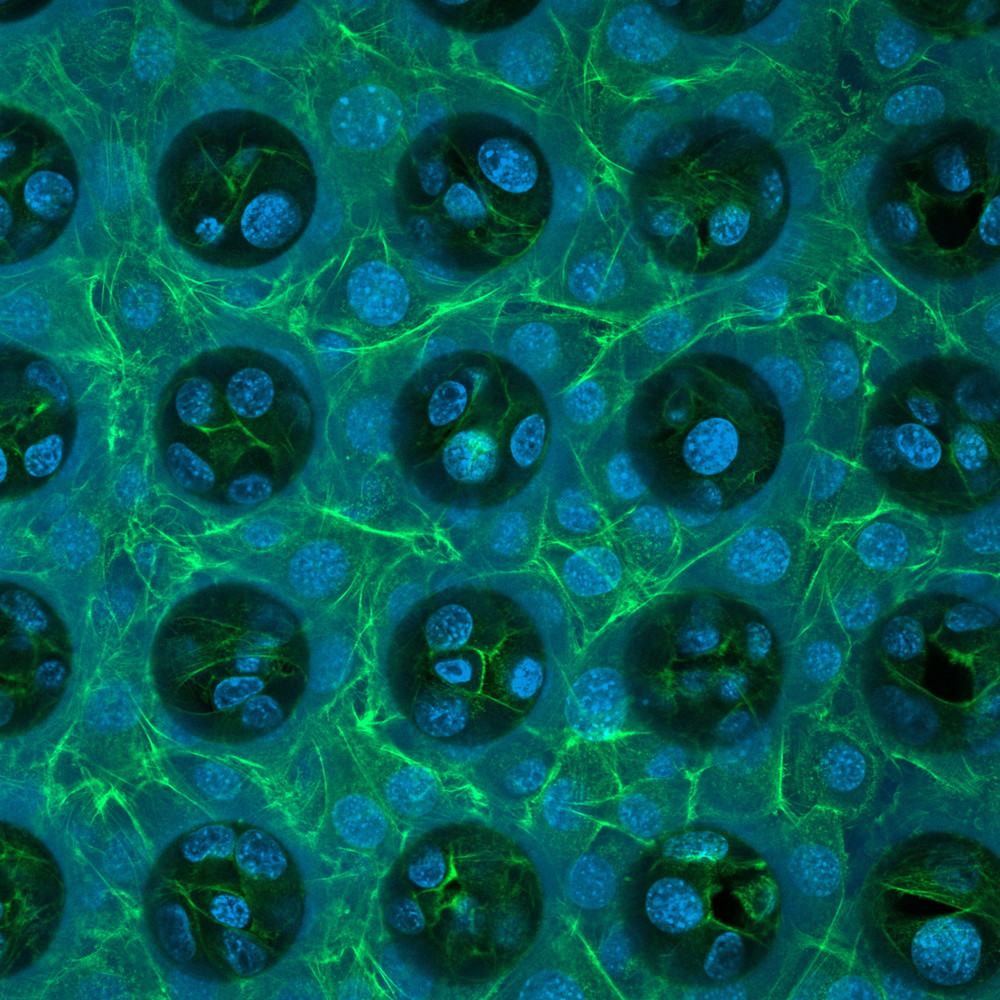

Img. 1: 3D printing of microwell arrays for the cell culturing. The fluorescent NIH 3T3 cells are attached to the biocompatible scaffold made of the photoresin Nanoscribe IP-S whereby they proliferate.

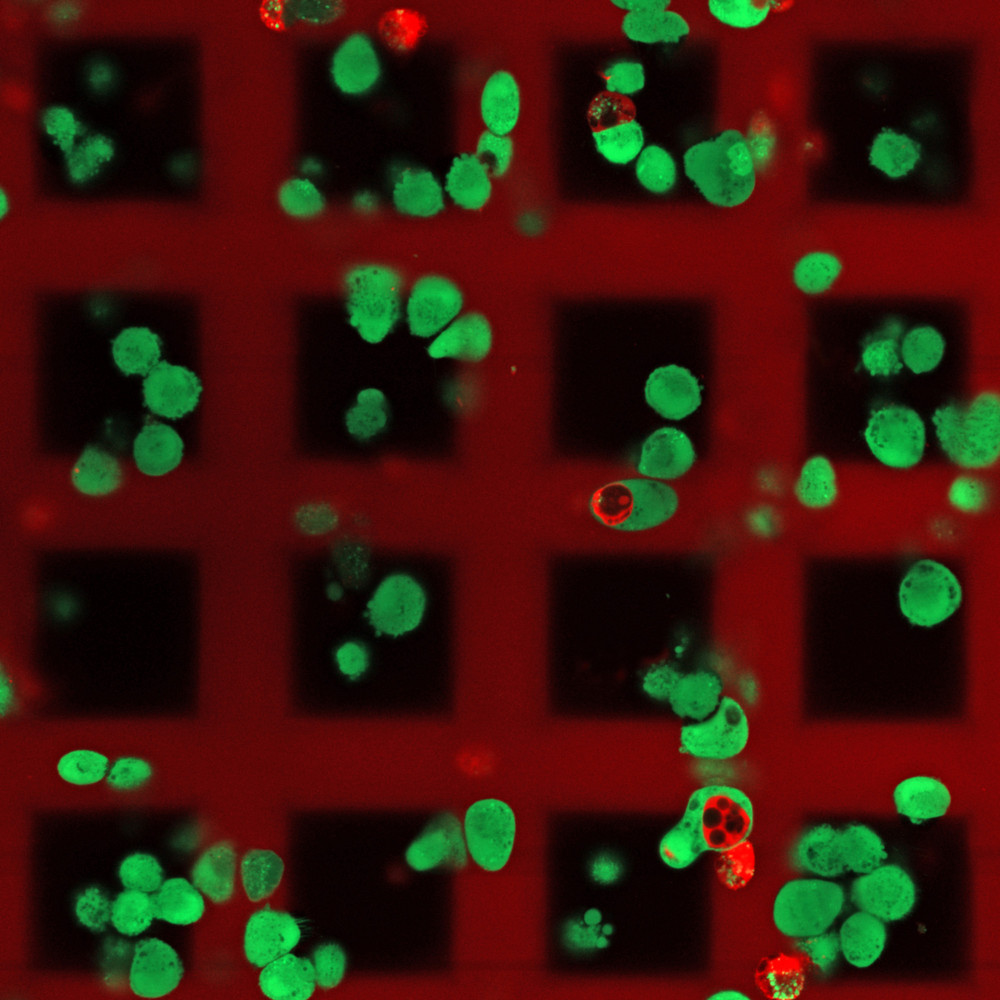

Img. 2: 3D structure containing living NIH 3T3 fibroblast cells, printed from a cell-laden Gelatin methacrylate (GelMA) bioresin. Cell viability one hour after printing is > 90 % as obtained by live-dead staining.

Img. 3: Microfabricated complex vascular models across multiple scales to mimic in vitro environments and phenomena. The image shows a simple vascular model with dyed water.

Right of use and media relations

Our image may be used free of charge for editorial purposes. Please state the source as follows: "Image: Nanoscribe, www.nanoscribe.com". The image must not be used for commercial purposes or passed on to third parties.

In case of questions or if you would like to be added to our press mailing list, please do not hesitate to contact Johannes Lang, media@nanoscribe.com.

Stay up to date with our latest press releases about Nanoscribe and the world of 3D Microfabrication. Directly get in touch with us to discuss further press activities: Media relations