nanoPrintX is much more than a 3D printer slicer software: it is a game changing tool for creating and aligning sophisticated print projects. Based on a scene graph concept that offers great flexibility and functional options, each node represents a print-relevant object or operation and includes a set of adjustable print properties. Several design files can be imported and organized into group or array nodes, or multiple files can be merged into one print object.

New opportunities with nanoprecision alignment in 3D printing

nanoPrintX unlocks the core capabilities of Aligned 2-Photon Lithography (A2PL®) technology for printing with Quantum X align. Individual alignment markers can be defined as well as substrate features such as chip edges and fiber facets. Using Quantum X align's confocal or fiber illumination unit, these substrate markers can be detected and matched to the digital model defined with nanoPrintX. In this way, freeform microoptics, for example, can be printed precisely aligned to the optical axes of fibers or photonic chips with submicron accuracy using the highest resolution 3D printer. Application examples are efficient optical interconnects for photonic integration and photonics packaging, and miniaturized optics for imaging and sensing applications such as minimally invasive endoscopy or light-based sensors.

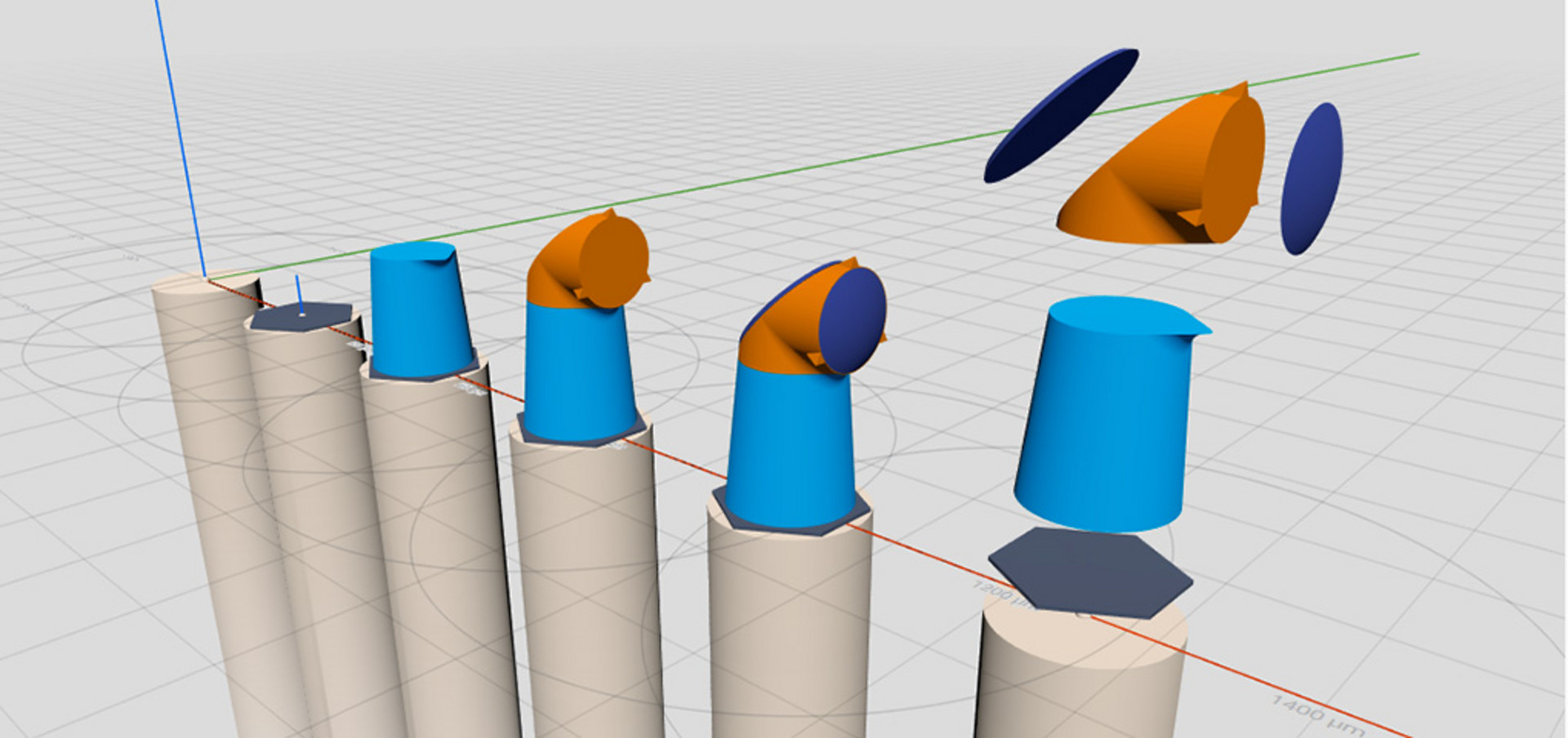

Composing aligned print projects with nanoPrintX

With nanoPrintX, any printing scenario can be defined by loading a virtual model of the substrate, such as optical fibers or photonic chips, with individual alignment markers. The 3D designs of the print objects can then be imported as STL or OBJ files and placed in the print scene. Pre-developed print parameters can be assigned to each individual design and work right out of the box. Finally, the print project is uploaded to Quantum X align, which takes care of the best possible print results.