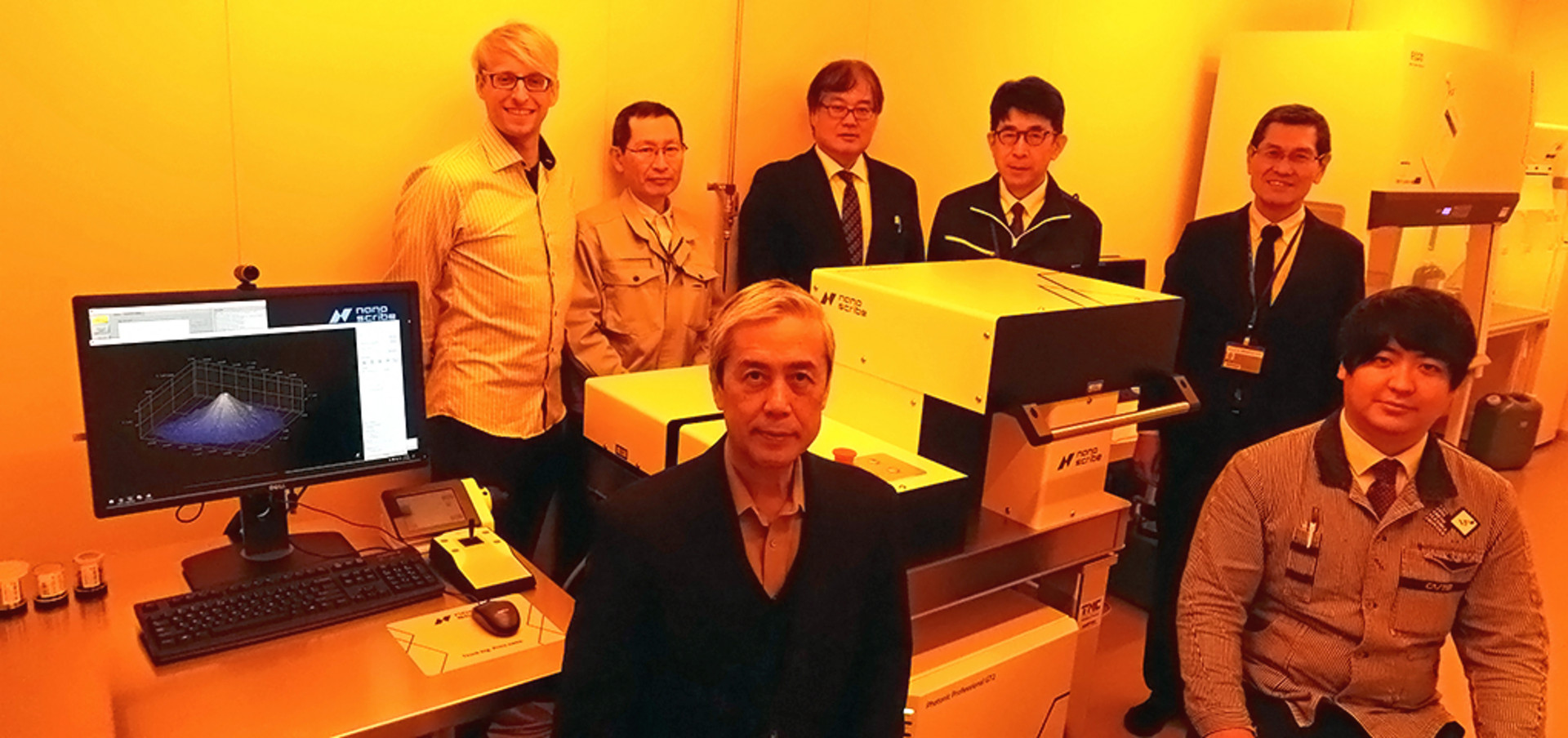

Under the leadership of Professor Osamu Tabata, the newly appointed Dean of the Faculty of Engineering at KUAS, the new Photonic Professional GT2 system will strengthen the state-of-the-art engineering facilities at KUAS. It will be utilized to bridge the multidisciplinary development in research and industry sectors ranging from mechatronics, biotechnology, microelectronics and optics to medical and materials engineering. Just one year after the first Photonic Professional GT2 installation at KEIO University in Tokyo and adding to previous Nanoscribe systems, Japan’s nano and microfabrication capacities have been expanded to a total of four Photonic Professional GT2 in science and industry.

Nanoscribe system boosting Nanotechnology Platform Japan

In the near future, the 3D Microfabrication system at KUAS will be expected to become a part of the Nanotechnology Platform Japan supported by the Ministry of Education, Culture, Sports, Science and Technology (MEXT). This project aims to establish a reliable research infrastructure for scientific innovation by the alliance of Japanese institutes and universities sharing cutting edge equipment and research know-how. The new Nanoscribe system and other resources for microstructuring, characterization as well as molecule and material synthesis methods will be available within this network.

Bridging science and industrial applications

KUAS and CASTEM Co. Ltd., a global company for metal parts manufacturing located in Fukuyama, are collaborating to nurture education of future engineers and to strengthen cooperation between science and industry. The company works in lost wax casting and metal injection molding. “As one of our approach, we concluded a collaboration agreement with CASTEM to promote the education, research and development using nano- and microfabrication,” explains Professor Osamu Tabata and Dean of the Faculty of Engineering at KUAS. “Together with CASTEM, we plan to establish the technology to utilize microstructures fabricated by the Nanoscribe system as a mold to cast the various metals. This technology will largely expand the application of 3D Microfabrication in various industrial applications”, Tabata added.