Responding to high manufacturing demand, e.g., in the sensors, mobile device, data and telecommunications sectors, the company has developed a system that redefines industrial 2D and 2.5D microfabrication. The new Quantum X is the world’s first industrial system based on Two-Photon Grayscale Lithography (2GL), the patent-pending technology developed by Nanoscribe. This printing technology combines the extraordinary performance of grayscale lithography with the precision and flexibility of Nanoscribe’s pioneering Two-Photon Polymerization technology. Quantum X provides a more flexible, straightforward and cost-effective maskless lithography solution for various use cases.

The device is developed for ultra-accurate and free-form microfabrication tasks without compromising speed. The new system is equipped with three live-view cameras for process control and a resin dispenser. To simplify the changeover between hardware configurations objective and sample holder recognition run automatically. Quantum X microfabrication drastically shortens design iteration cycles, saving precious time along the complete printing process. The result is a strong cut of development and production costs and the acceleration of production chains.

Refractive and diffractive micro-optics

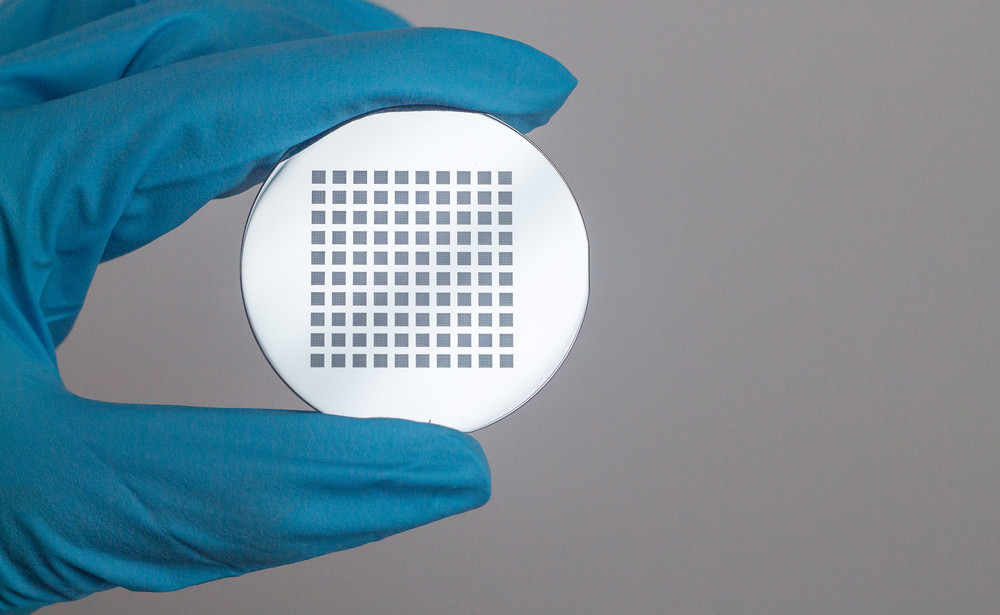

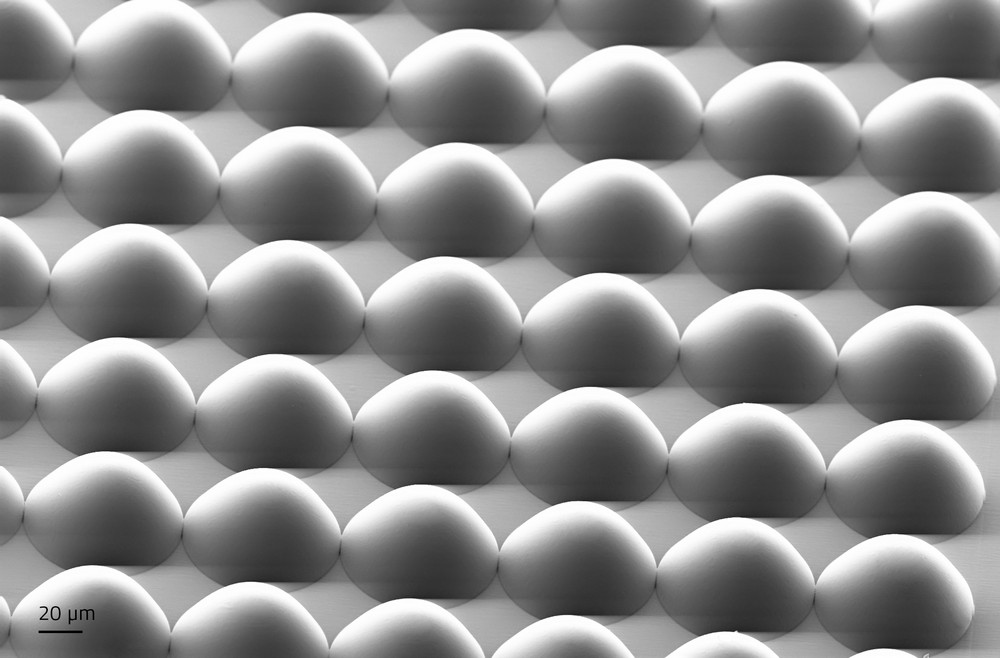

Multilevel diffractive optical elements (DOE) can now be produced by modulating the laser power in one scanning plane, reducing print time necessary for multi-layer microfabrication. Also, refractive microoptics benefit from the excellent contouring capabilities achieved with 2GL processes, making single optical elements, arrays with high fill factors of up to 100% and varying shapes such as spherical and aspherical lenses possible in a direct and maskless process. Quantum X fabricates almost any imaginable 2.5D shape on the microscale, something inconceivable before, paving the way to new or strongly enhanced optical elements from imaging, illumination to sensing.

Powerful and user-friendly software

Quantum X software controls and monitors print jobs in real time and supports intuitive operation by means of an interactive touchscreen control panel. The Quantum X developers have put great effort to excel in advanced user–machine interactions. For example, users can now check on the job status, adjust process controls and visualize printing in real time, directly on the built-in touchscreen. To manage and organize the users´ projects, a continuous execution of a series of print jobs is supported by a job queue.

The Quantum X software provides a wizard that guides designers and engineers through print job creation from the very beginning, simplifying job preparation. The integrated software accepts grayscale images of arbitrary optical designs. For example, BMP, PNG or TIFF of up to 32-bit resolution are accepted and prepared for direct fabrication with the Nanoscribe Quantum X.