The first installation of a Photonic Professional GT2 in Japan could be considered a journey back to the starting point of the technology of two-photon polymerization (2PP) which is the technological base of Nanoscribe’s 3D printers. In 1997 Professor Satoshi Kawata provided the experimental proof of two-photon polymerization in Japan. For more than ten years, Nanoscribe utilizes 2PP’s strength to expose photoresists with extreme focus and highest resolution for the direct fabrication of nano- and microstructures that are otherwise impossible to produce.

Relaunched in December 2018, the model Photonic Professional GT2 pushes the boundaries of nano- and microfabrication offering new solutions for additive manufacturing and maskless lithography. Thanks to optimized hardware and software components as well as new printing materials specially developed for larger volumes, high-resolution microstructures up to a height of 8 mm can now be produced for the first time. While Nanoscribe devices have always been optimally suited to the additive production of the finest structures, objects with submicrometer details from typically 160 nanometers up to the millimeter range on a printing area of up to 100x100 mm² can now be produced in a very short time.

Captions

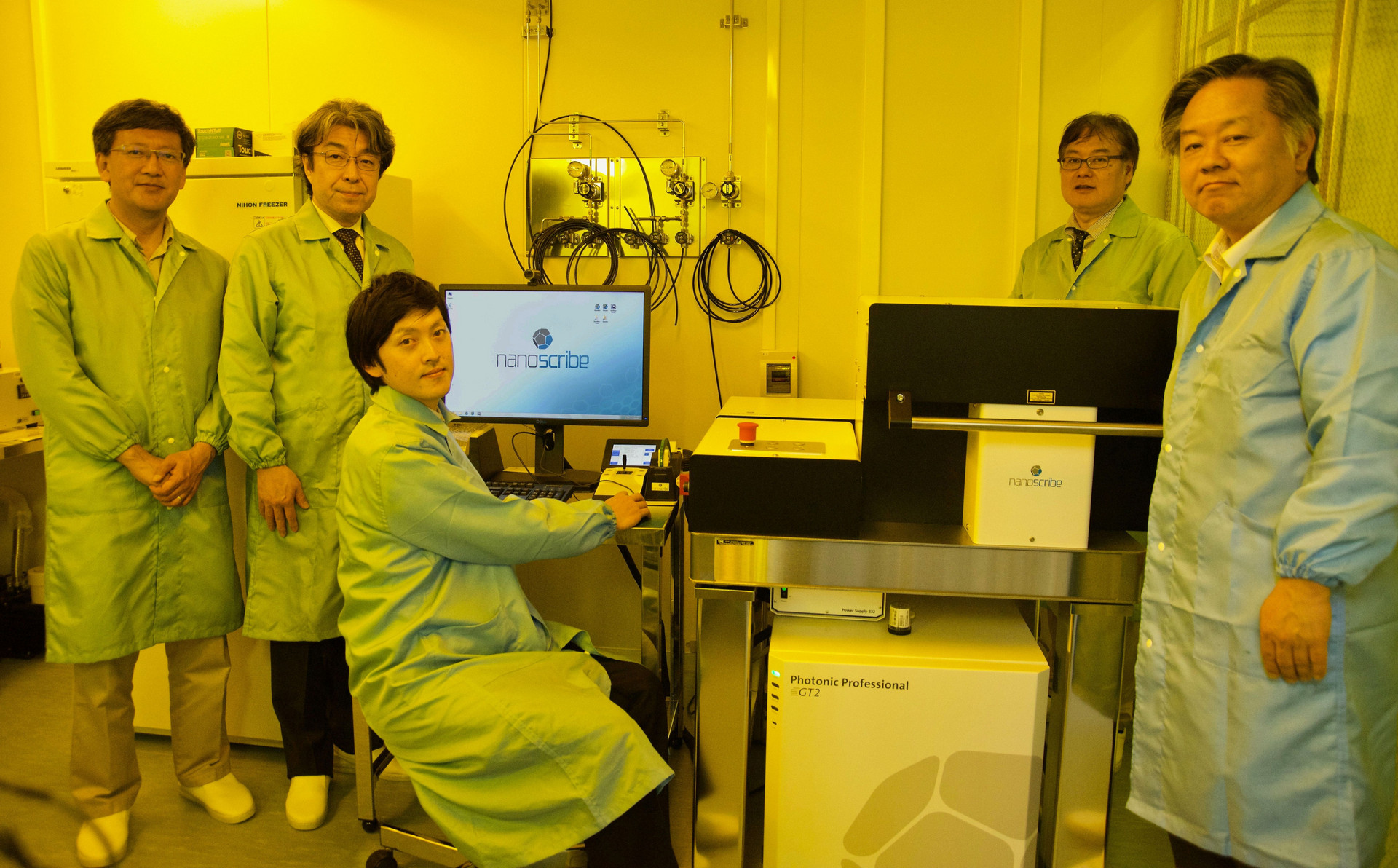

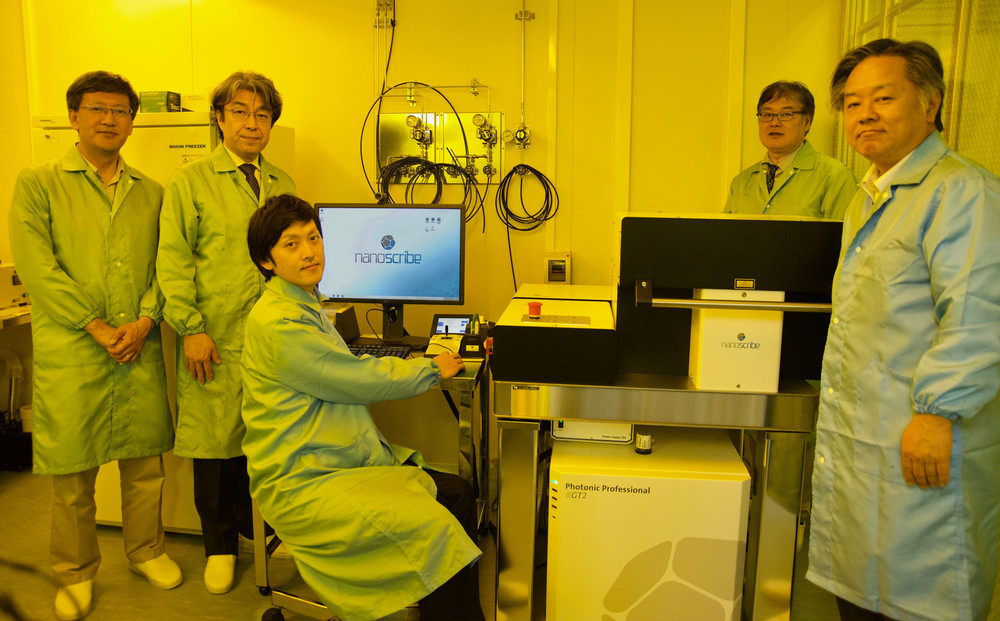

Img. 1: LTR: Prof. Dr. Kotaro Oka, Dep. of Biosciences and Informatics / Prof. Dr. Keiya Shirahama, Faculty of Science and Technology / Ryosuke Terada, Central Service Facilities for Research / Hayato Tsuruta, Japan Laser Corp. / Tomoaki Mitani, Central Service Facilities for Research

Right of use and media relations

Our images may be used free of charge for editorial purposes. Please state the source as follows: "Image: Nanoscribe". The images must not be used for commercial purposes or passed on to third parties.

In case of questions or if you would like to be added to our press mailing list, please do not hesitate to contact Anke Werner werner@nanoscribe.com.

Stay up to date with our latest press releases about Nanoscribe and the world of 3D Microfabrication. Directly get in touch with us to discuss further press activities: Media relations