Specifically designed for

printing with Quantum X systems

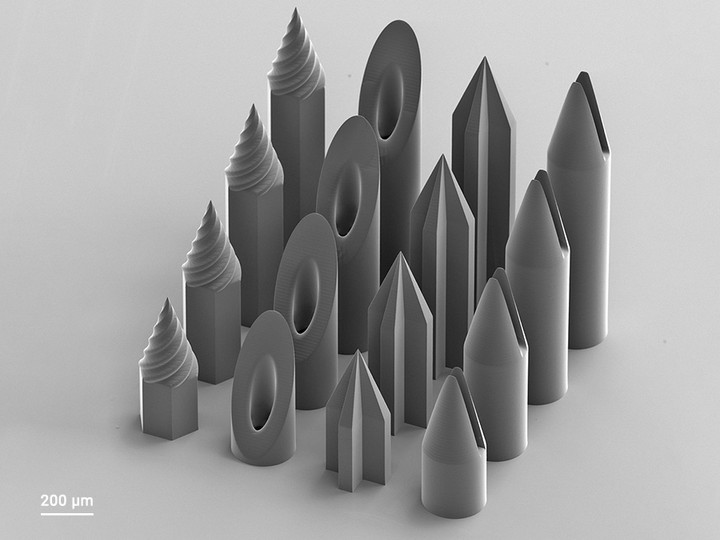

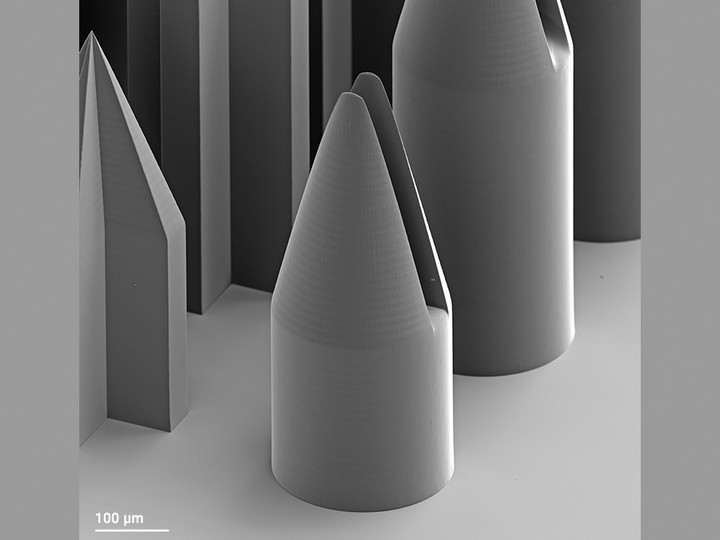

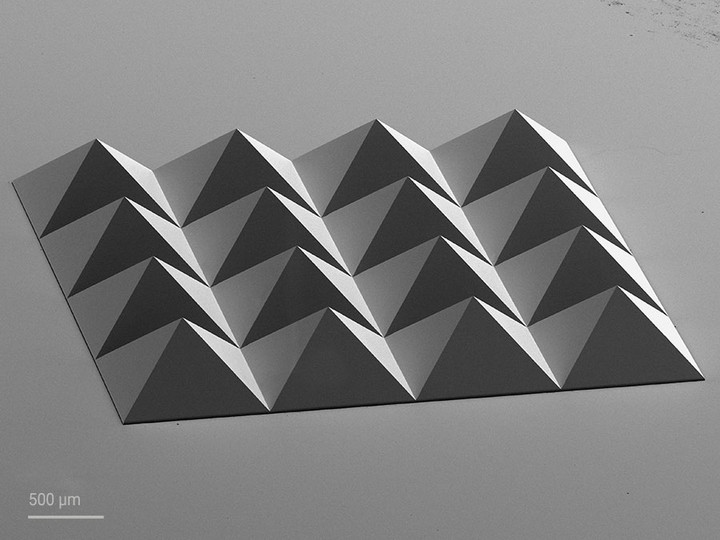

The new IPX Photoresins have been specifically designed for Nanoscribe Quantum X systems. The industry-proven platform offers high-precision 3D printing and the innovative Two-Photon Grayscale Lithography technology for 2.5D microfabrication. To benefit from the printing speed, precision and performance of the Quantum X platform, the new IPX photoresin series of photopolymer printing materials has been developed for different structure qualities and processes. IPX-S and IPX-Q are designed for printing mesoscale structures with micrometer precision using Two-Photon Grayscale Lithography and Two-Photon Polymerization correspondingly. IPX-M is the photoresin for high-throughput macroscale printing for print volumes up to 30 cubic centimeters in one pass.

Dr. Alexander Quick, Head of Materials: Development and Production, Nanoscribe

IPX Photoresins enable true high-performance printing with maximum possible throughput while maintaining best precision with Quantum X systems.

Explore material details

| Resin | Advantages | Possible applications |

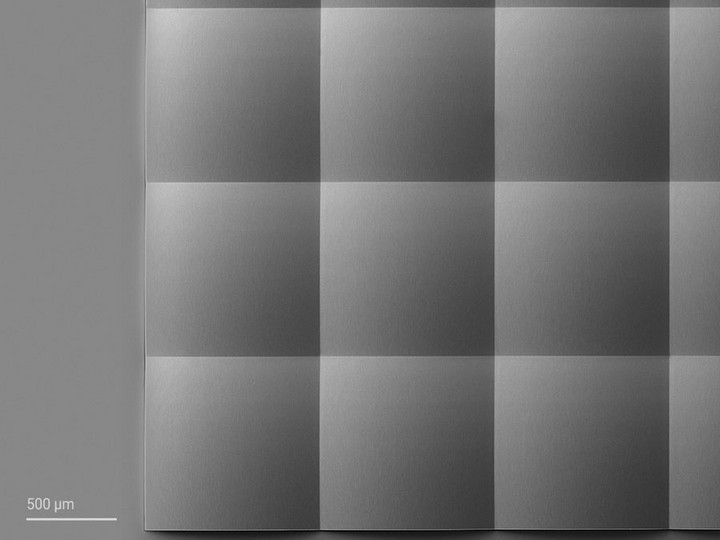

| IPX-S | Rapid 2GL printing for 2.5D Microfabrication of micrometer- and millimeter-scale optics. High optical quality with smooth surfaces and excellent shape accuracy. | Rapid prototyping and mastering: 2.5D microoptics, microlens arrays, Fresnel lenses, hybrid and freeform lenses, and prism arrays. |

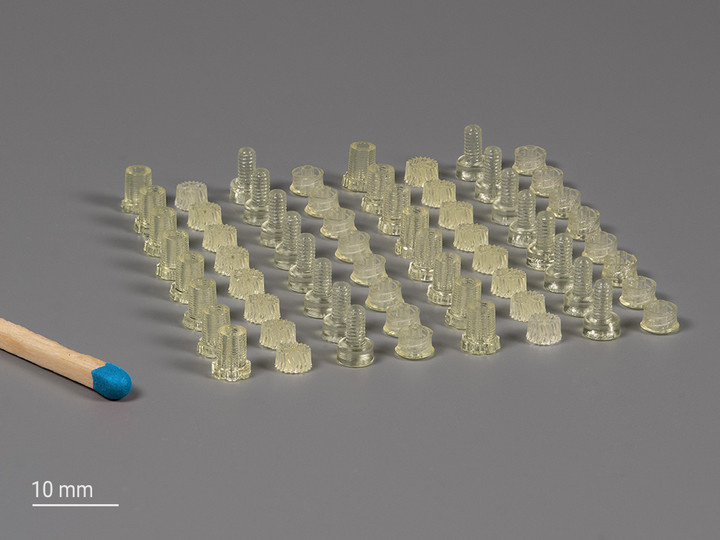

IPX-Q | Rapid 2PP-based 3D Microfabrication. Printing up to centimeter-sized 3D objects. Parts with high aspect ratios and excellent shape accuracy. | Rapid prototyping: Life sciences, microfluidics, microneedles, mechanical components. |

New | High-throughput macroscale 3D printing for print volumes up to 30 cm³. Full design freedom for 3D objects with arbitrary shapes and high aspect ratios. | Rapid prototyping and batch production: Mechanical components, etc. |

| Properties | Refractive index 1 @589 nm, 20 °C | Young‘s modulus 1 [GPa] | Biocompatibility2 | Classification / Print set |

| IPX-S | 1.510 | 2.2 | yes | Universal / LF |

| IPX-Q | 1.511 | 2.2 | yes | Universal / LF and XLF |

| IPX-M | 1.499 | 1.3 | yes3 | Universal / XLF |

1 measured on 3D printed structures; results depend on the printing conditions and geometry

2 Non-cytotoxic according to ISO-10993-5

3 No cytotoxic effect but a slight reactivitiy according to ISO-10993-5

Print Sets: XLF – Extra Large Features; LF – Large Features

The microfabrication devices from Nanoscribe are designed as open systems, suitable for a broad selection of materials. The variety of materials extends further to third-party UV-curable photoresists, hydrogels and custom-made materials.

To satisfy the needs of material developers for testing new resins, a variety of materials and processes allow optical, mechanical, electrical, chemical and biological properties to be tuned as needed, e.g., in optics, photonics or biomedical engineering.

Post-print processes, e.g., casting, atomic layer deposition (ALD), chemical vapor deposition (CVD) or galvanization, allow modification of the 3D printed structures and permit the inclusion of further materials including ceramics, metals, glass or other plastics.

Improved performance, precision and print speed

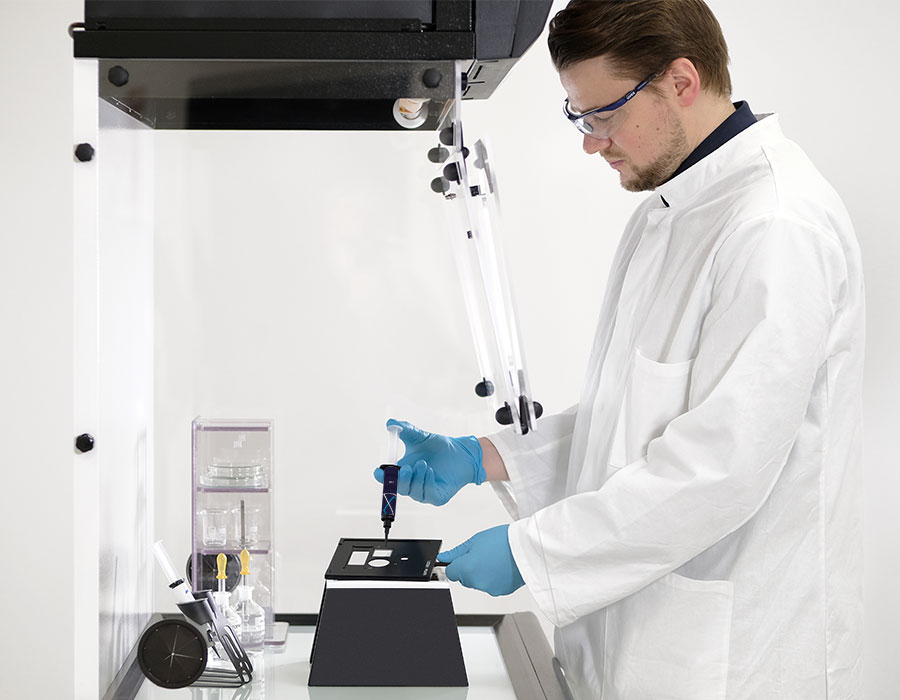

Precise and clean dispensing of printing materials

Our photoresins are available in lightproof and resealable cartridges. Take advantage of convenient dosing by hand or automatic dispensing onto substrates, wafers, chips and other microparts – precise and bubble-free. Further advantages:

- Improved cleanliness

- Better handling and dispensing

- High-yield dispensing

Interested in our

IP Photoresins for Two-Photon Polymerization?

Explore our universal and functional photopolymers for 3D Microfabrication.