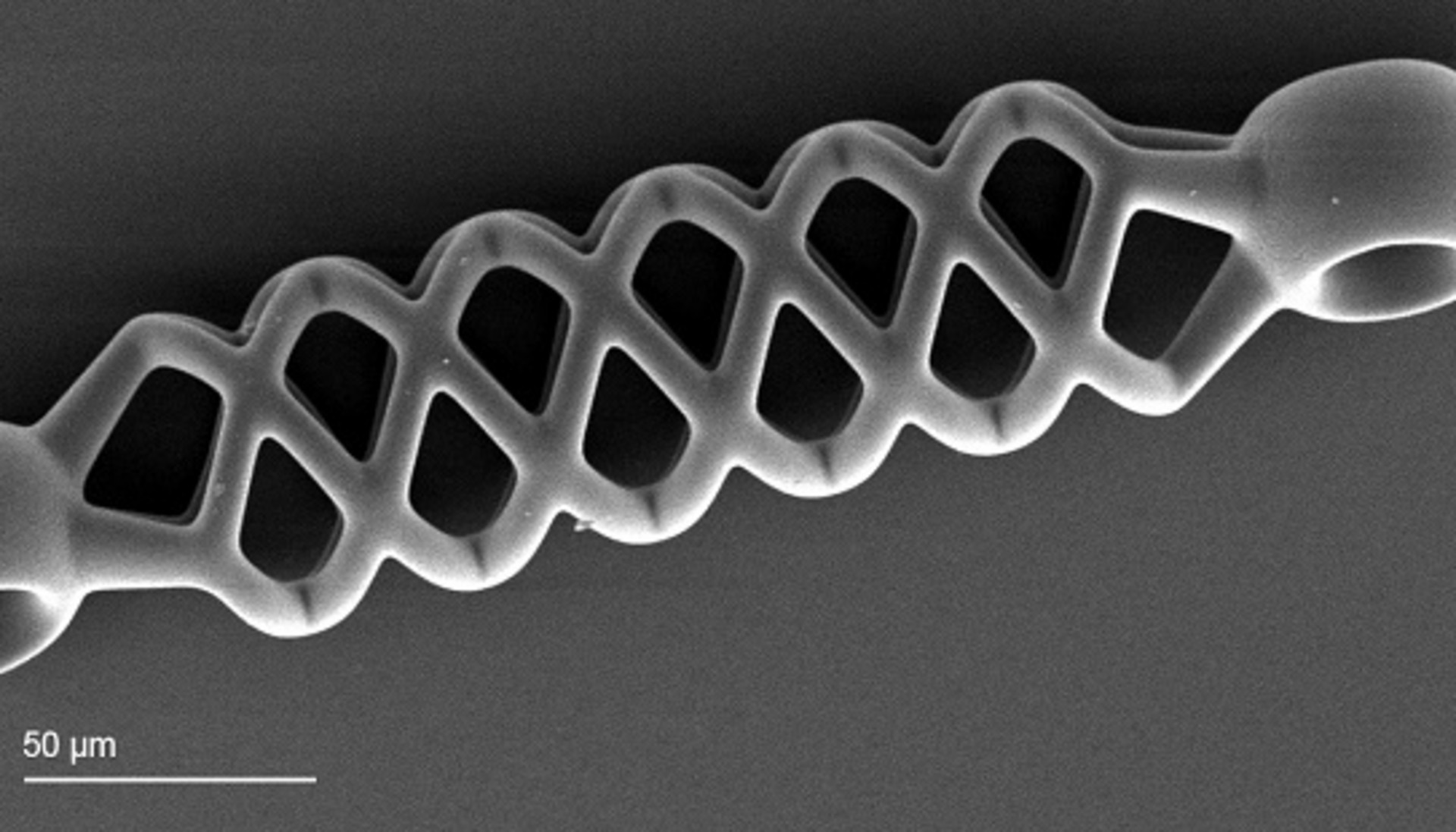

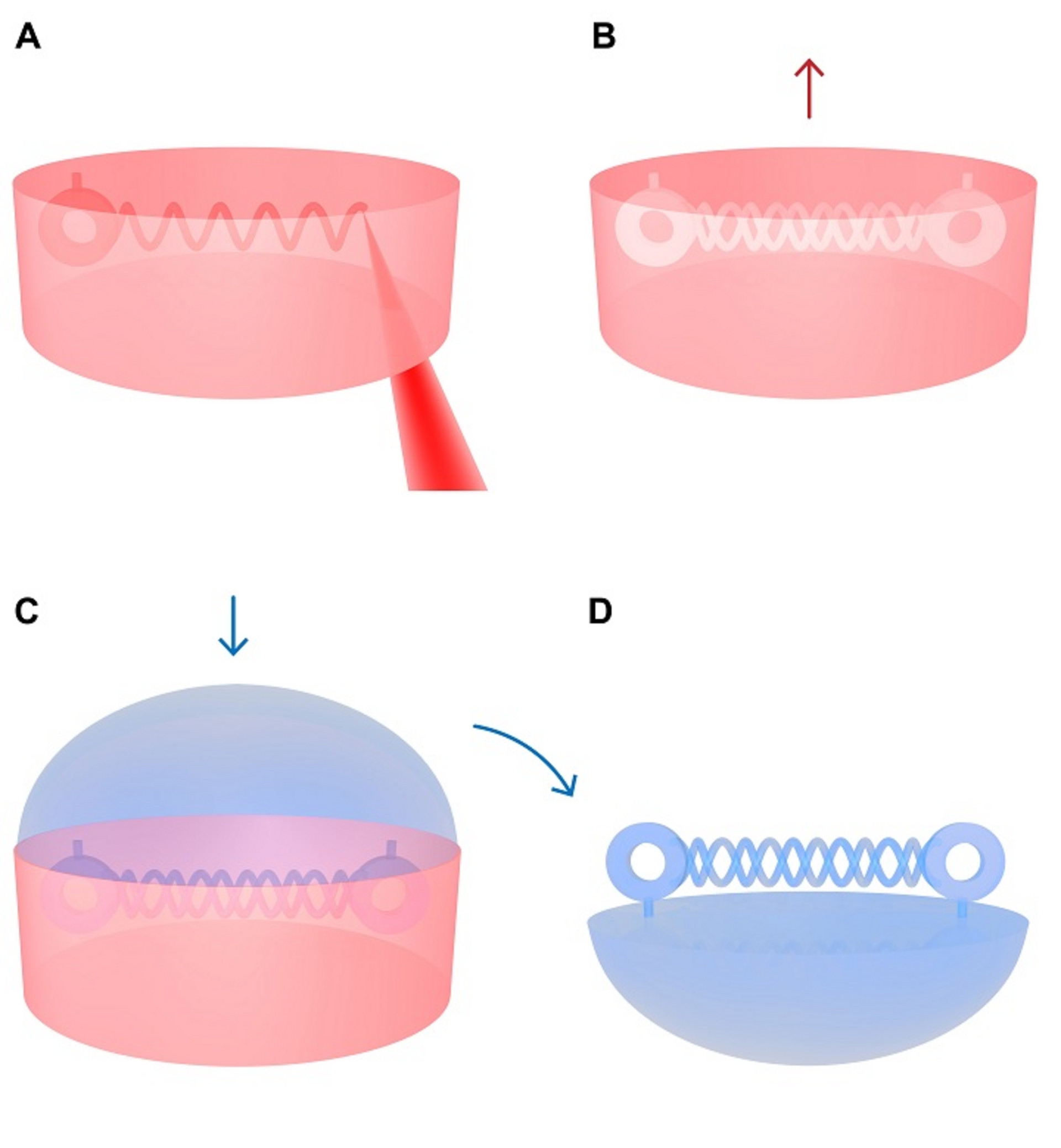

Scientists at the Multi-Scale Robotics Lab at the ETH Zürich in collaboration with the Politecnico di Milano and Kantonsspital Aarau used a Nanoscribe Photonic Professional system to develop a novel indirect 4D printing method. They applied this technique to fabricate soft robotic stents on the microscale. The 3D printed sacrificial templates of the lattice scaffold are fabricated by Nanoscribe technology and subsequently molded into shape memory polymers (SMP) to adopt the complex 3D shape of the printed template. The shape memory microstents are able to deform under heating and cooling conditions, even showing shape recovery.

Individualized designs for medical microdevices

4D printed microstructures are promising components in microsurgery and further minimally invasive methods for treating medical diseases with high-precision instrumentation. The implementation of soft robotic microstents represents a step forward into applying microtechnologies to solve life-threatening conditions, for example in pediatric diseases such as congenital obstructive uropathies. The pioneering work on shape-reactive microstents could pave the way for the development of novel medical microdevices with complex and individual 3D designs.

Microstructures having shape memory

On the macroscale, shape memory polymers are the most investigated materials using the process known as 4D printing. Under external stimuli these materials transform and undergo physical and chemical changes over time. Thus, the properties of morphing give 4D printing its fourth dimension: time. But shape memory polymers have so far not been explored on the microscale. Reports of 4D printing with these materials show structures limited to resolutions of 200 µm at best.