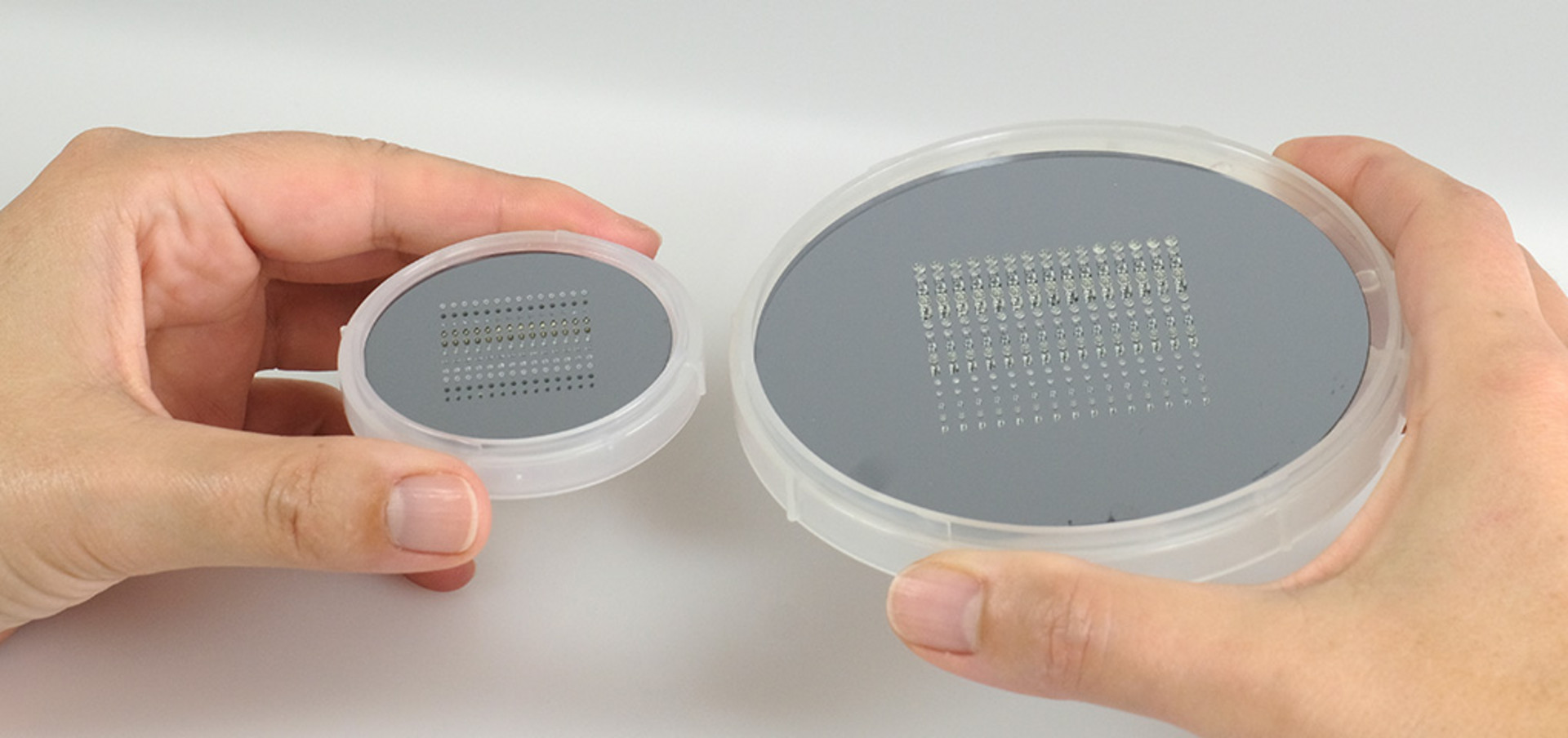

Piloted process chain for microoptics mastering and replication by NIL and IM

Nanoscribe’s proprietary Two-Photon Grayscale Lithography (2GL ®) significantly speeds up the high-precision microfabrication of 2.5D structures for optical applications, such as prototyping or mastering of freeform microoptics, microlens arrays, and multilevel diffractive optical elements with the highest shape accuracy and optical-grade surfaces (Ra ≤ 5 nm). To scale up production even further, combining 2GL mastering with replication technologies comes into play. With nanoimprint lithography (NIL) and injection molding (IM), Nanoscribe has already piloted two reliable and proven replication strategies. As a highlight, the program at the Nanoscribe booth includes joint presentations with EV Group and kdg Opticomp, explaining both replication approaches and the process chain starting with Quantum X manufactured microoptics in more detail. The aim of the talks is to outline the short design iteration cycles of the 2GL additive manufacturing process, which allow masters for replication to be produced within a few days, thus moving microoptics manufacturing into mass production.

Three classes of printing materials for various applications

Advances in microfabrication are closely linked to printing materials. This year, Nanoscribe expanded its photoresin portfolio from polymer-based IP photoresins to include a new silica nanocomposite for 3D printing fused silica microstructures and Xpect Inx Photoresins for 3D printing biomaterials.

The new GP-Silica, developed in collaboration with the German company Glassomer, enables 3D printing of glass with micrometer precision. Thanks to an optical transmission window that extends from the UV to the infrared region combined with thermal, mechanical and chemical stability, the new material is also suitable for applications in life sciences, microfluidics, microreactors or microoptics. The new Xpect Inx N100 series, which consists of three hydrogels and biodegradable photoresins for Nanoscribe systems, advances 3D biomaterial printing in life sciences, e.g. with applications in tissue engineering and cell cultivation.

Meet us at Formnext for insights into 3D printing from nano to macro

At Formnext (hall 12.1, booth G61), Nanoscribe will showcase samples of mechanical components and refractive microoptics masters fabricated with Quantum X systems, as well as the corresponding replicas of EV Group with nanoimprint lithography and kdg Opticomp with injection molding. Demo sessions will provide an overview of the lean and user-friendly workflow of the new Quantum X shape. The booth will also feature a Lumen X+™ printer from the BICO company CELLINK to provide even more hands-on insights into 3D printing for life science applications. The DLP-based 3D printer is suited for a wide range of photoresins and for bioprinting. We are looking forward to your visit.