The Glass Printing Explorer Set is beneficial for high-precision 3D printing of applications for which high temperature resistance combined which mechanical and chemical stability as well as optical transparency are crucial. Two-Photon Polymerization (2PP) of fused silica glass advances the exploration of new applications in life sciences, microfluidics, microoptics and other fields by providing researchers with the superior properties of glass. “GP-Silica has great potential for our research manufacturing complex microfluidics systems, although the required thermal post-processing is demanding”, says Professor Dr. Nicolas Muller, Assistant Professor and Head of Graphical Printing at the School of Engineering and Architecture of Fribourg (Switzerland), summarizing the opportunities offered by the photoresin with regard to his intended research projects.

Glass as a new class of printing materials in 3D Microfabrication

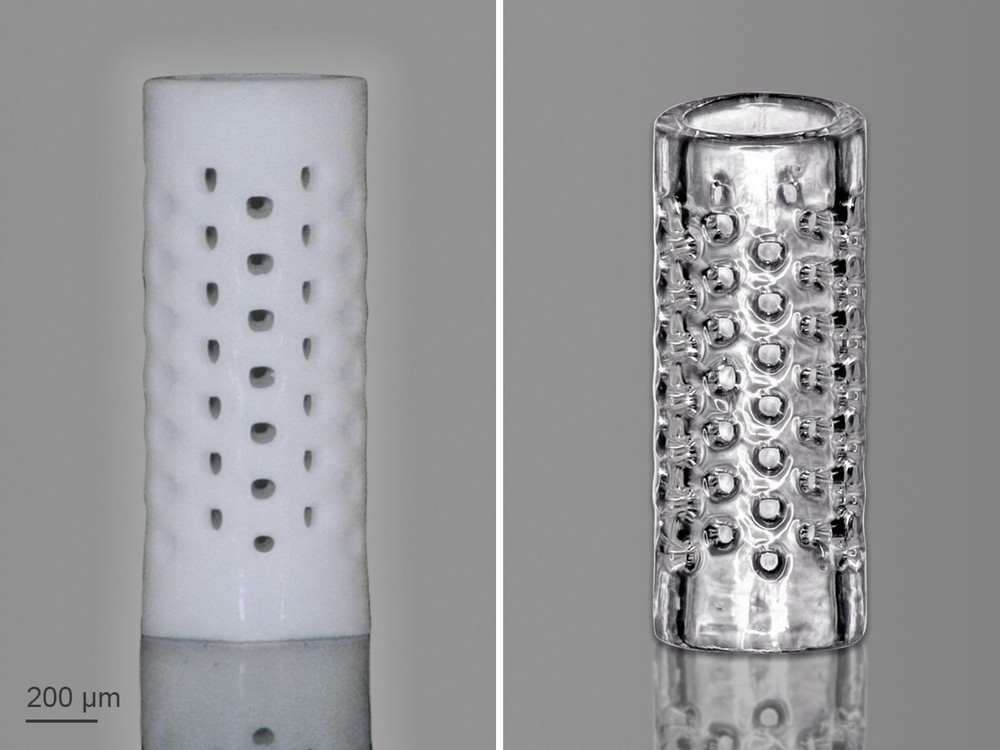

The new photoresin GP-Silica establishes a new material class for Two-Photon Polymerization based 3D Microfabrication and was developed in collaboration with Glassomer GmbH, a recognized specialist in room temperature shaping glass. The inorganic printing material is a composite of silica nanoparticles dispersed in a photocurable binder matrix and features outstanding characteristics of silica glass, such as high mechanical, thermal and chemical stability. This enables the 3D printing of glass microstructures with smooth optical quality surfaces. Due to an optical transmission window that extends from the UV to the infrared region, the new material is also suitable for imaging applications in life sciences, microfluidics, microreactors or microoptics.

How to combine 3D printing with the processing of glass

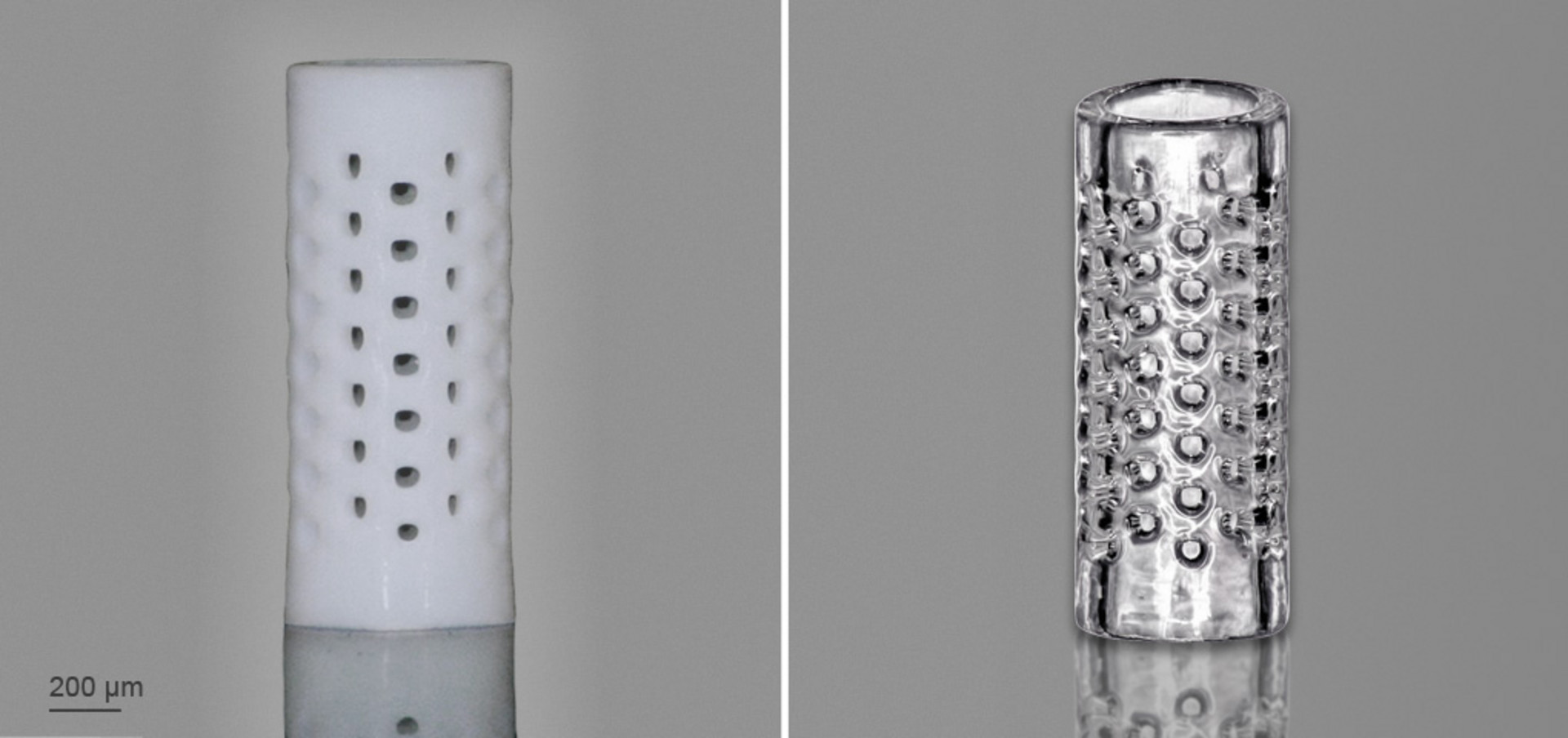

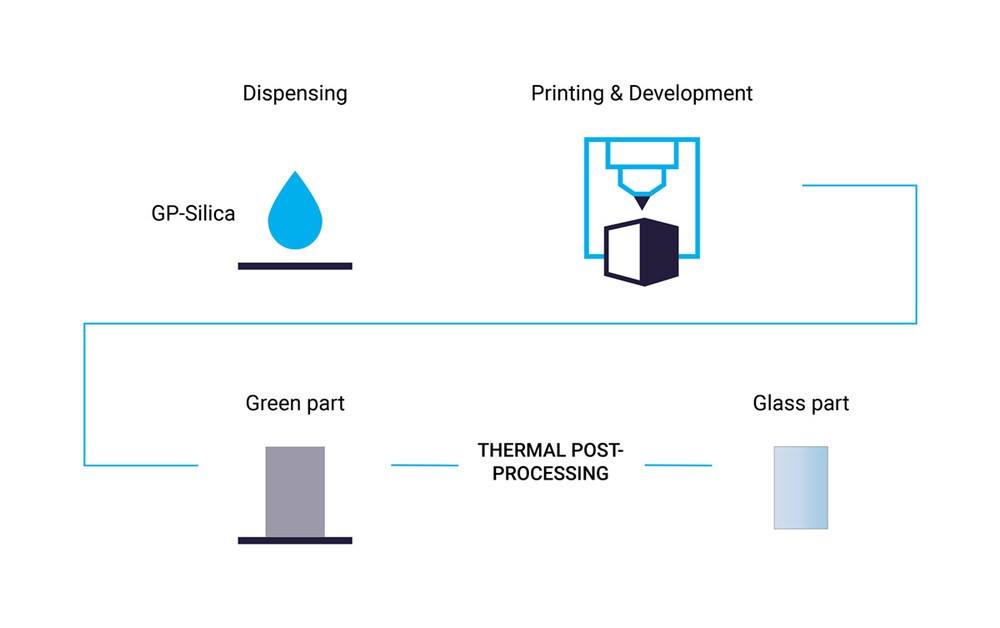

The new photoresin is a novel material for 3D Microfabrication and optimized for Nanoscribe 3D printers. As typical for glass manufacturing, thermal treatments are necessary: The fabrication process starts with the familiar high-precision 3D printing process of microstructures. The resulting green parts consist of silica nanoparticles homogeneously suspended in a polymer binder matrix. In a two-stage thermal process, the polymer is first removed from the printed microstructure. In a second step, the silica nanoparticles fuse together to form the final microstructure of pure fused silica glass (see image 4). All in all, the Glass Printing Explorer Set is the optimal starting point for the high-precision additive manufacturing of glass microstructures that feature material properties that are identical to that of other commercially available fused silica.

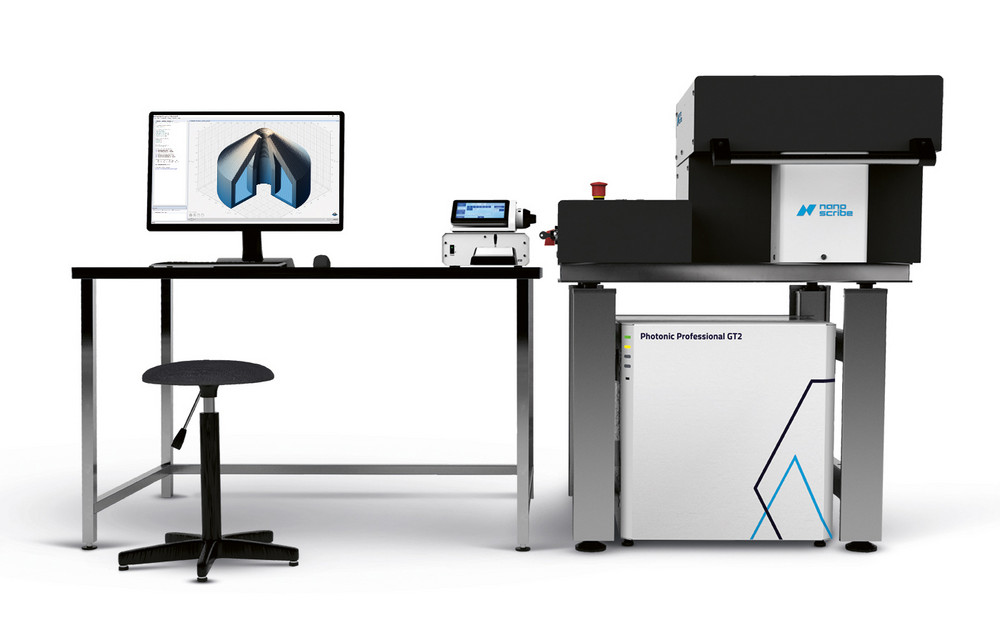

About Nanoscribe

The medium-sized company develops and produces 3D printers and maskless lithography systems for microfabrication as well as specially developed printing materials and application-specific solution sets. The specialist for additive manufacturing of high-precision structures and objects on the nano-, micro- and mesoscale was founded in 2007 as a spin-off of the Karlsruhe Institute of Technology (KIT) and is part of the CELLINK Group since June 2021.