To scale up production even further, combining 2GL mastering with replication technologies comes into play. With nanoimprint lithography (NIL) and injection molding (IM), Nanoscribe has already piloted two reliable and proven replication strategies. As a highlight, the program at the Nanoscribe booth includes joint presentations with EV Group and kdg Opticomp, explaining both replication approaches and the process chain starting with Quantum X manufactured microoptics in more detail. The aim of the talks is to outline the short design iteration cycles of the 2GL additive manufacturing process, which allow masters for replication to be produced within a few days, thus moving microoptics manufacturing into mass production.

Three classes of printing materials for various applications

Advances in microfabrication are closely linked to printing materials. This year, Nanoscribe expanded its photoresin portfolio from polymer-based IP photoresins to include a new silica nanocomposite for 3D printing fused silica microstructures and Xpect Inx Photoresins for 3D printing biomaterials.

The new GP-Silica, developed in collaboration with the German company Glassomer, enables 3D printing of glass with micrometer precision. Thanks to an optical transmission window that extends from the UV to the infrared region combined with thermal, mechanical and chemical stability, the new material is also suitable for applications in life sciences, microfluidics, microreactors or microoptics. The new Xpect Inx N100 series, which consists of three hydrogels and biodegradable photoresins for Nanoscribe systems, advances 3D biomaterial printing in life sciences, e.g. with applications in tissue engineering and cell cultivation.

Discover 3D printing solutions ranging from nano to macro

At Formnext (hall 12.1, booth G61), Nanoscribe will showcase samples of mechanical components and refractive microoptics masters fabricated with Quantum X systems, as well as the corresponding replicas of EV Group with nanoimprint lithography and kdg Opticomp with injection molding. Demo sessions will provide an overview of the lean and user-friendly workflow of the new Quantum X shape. The booth will also feature a Lumen X+™ printer from the BICO company CELLINK to provide even more hands-on insights into 3D printing for life science applications. The DLP-based 3D printer is suited for a wide range of photoresins and for bioprinting. We are looking forward to your visit.

About Nanoscribe

The medium-sized company develops and produces 3D printers and maskless lithography systems for microfabrication as well as specially developed printing materials and application-specific solution sets. The specialist for additive manufacturing of high-precision structures and objects on the nano-, micro- and mesoscale was founded in 2007 as a spin-off of the Karlsruhe Institute of Technology (KIT) and has been part of the BICO Group since June 2021. More than 3,000 users and operators at top universities and innovative industrial companies worldwide benefit from the groundbreaking technology and application tailored solutions for 3D Microfabrication. Nanoscribe has created its strong market leading position through high quality engineering and agility to continuously develop its products to meet customers’ high expectations.

About BICO

Founded in 2016, BICO (formerly CELLINK) is the leading bio convergence company in the world. By combining different technologies, such as robotics, artificial intelligence, computer science, and 3D bioprinting with biology, we enable our customers to improve people's health and lives for the better.

With a focus on the application areas of bioprinting, multiomics, cell line development, and diagnostics, the company develops and markets innovative technologies that enable researchers in the life sciences to culture cells in 3D, perform high-throughput drug screening and print human tissues and organs for the medical, pharmaceutical, and cosmetic industries. We create the future of health.

The Group’s instruments in the field amounts to 25,000, including all the top 20 pharmaceutical companies, are being used in more than 65 countries, and have been cited in more than 9,500 publications. BICO is listed on Nasdaq Stockholm under BICO. www.bico.com

Captions

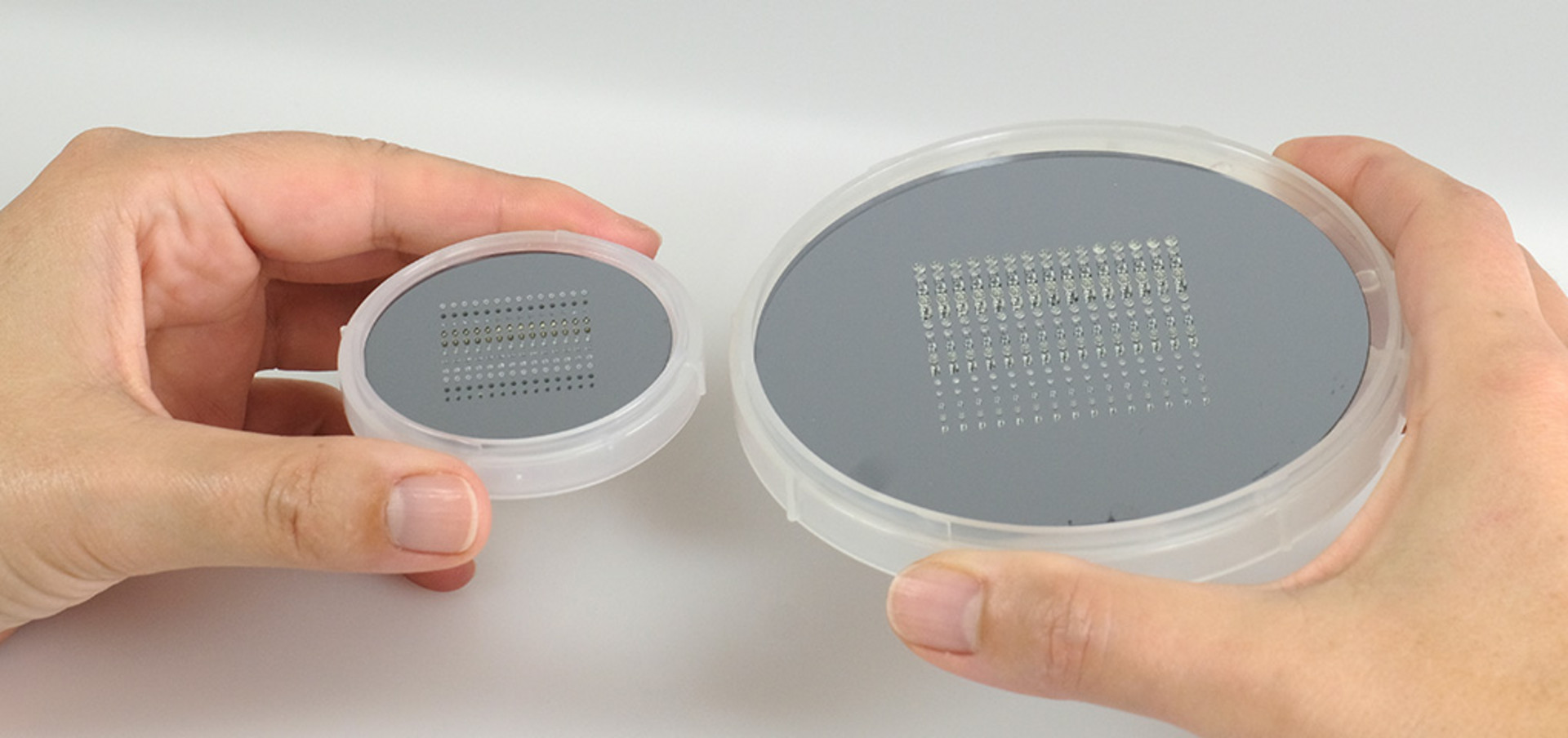

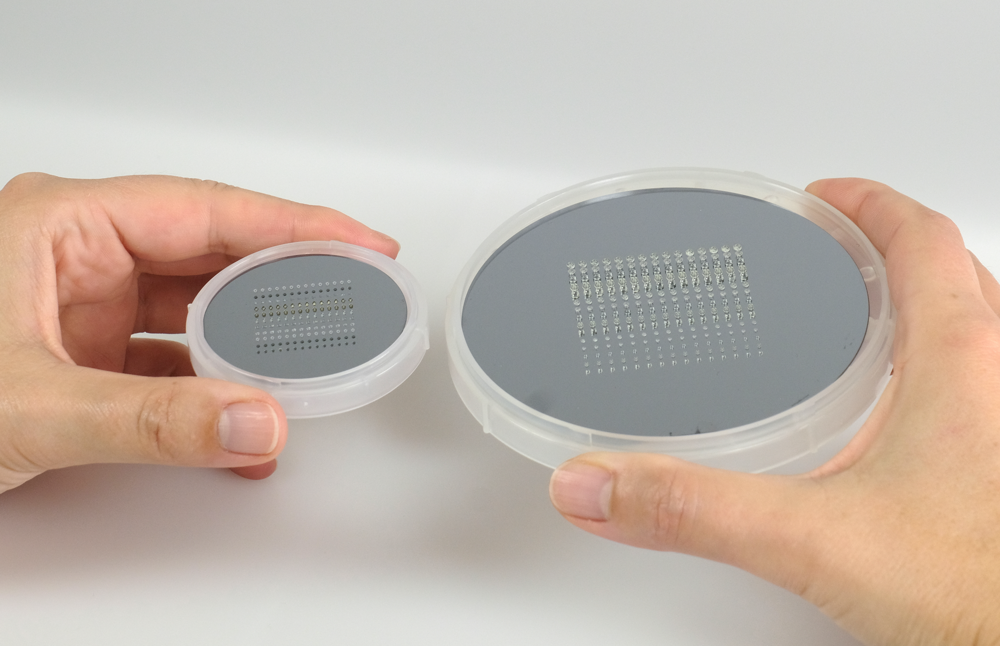

Img. 1: Fascinating advances in wafer-scale batch processing: At the last Formnext in 2019, visitors gained insights into the small series production of millimeter-sized elements on wafers up to 2’’. With the new Quantum X shape, precision and speed are significantly increased and small series production is now possible on wafers up to 6''.

Img. 2: Nanoscribe’s new high-precision 3D printer Quantum X shape next to the world's first Two-Photon Grayscale Lithography (2GL ®) system Quantum X.

Img. 3: A Nickel shim is fabricated from the 2GL printed polymer master and embedded in an injection molding machine for mass production. Image: kdg Opticomp

Right of use and media relations

Our image may be used free of charge for editorial purposes. Please state the source as follows: "Image: Nanoscribe, www.nanoscribe.com". The image must not be used for commercial purposes or passed on to third parties.

In case of questions or if you would like to be added to our press mailing list, please do not hesitate to contact Dr. Alena Kirchenbauer, media@nanoscribe.com.

Stay up to date with our latest press releases about Nanoscribe and the world of 3D Microfabrication. Directly get in touch with us to discuss further press activities: Media relations