The multidisciplinary field of microfluidics focuses on the precise control and manipulation of liquids in very small volumes. Microfluidic devices are needed e.g. in lab-on-a-chip applications for chemical, biological or physical studies. To investigate phenomena occurring at a small scale, microfluidic channels are manipulated by the integration of even smaller elements. As such, microfluidic channels are combined with active and passive components like filters, valves or mixers. However, conventional microfabrication techniques of microfluidic chips have been limited to planar structures, holding back the exploitation of three-dimensional architectures, e.g. for multi-phase droplet separation, swap-mixing or wet-phase fiber spinning. Using Nanoscribe’s Photonic Professional systems, scientists from the DWI Leibniz-Institute for Interactive Materials and the RWTH Aachen University tackle the challenge to fabricate and integrate 3D microstructures into 2D microfluidic channels with a novel method. Namely, they apply Two-Photon Polymerization for mastering of microfluidic channels and for in-chip printing inside the sealed channel system, establishing a new microfabrication method for microfluidics.

3D Microfabrication advances microfluidic applications

Additive manufacturing by 2PP technology enables three-dimensional structures whose geometries go beyond the planar environments known in 2D microfluidic platforms. The technology is used to fabricate free-standing 3D microstructures, but with the high-precision positioning systems in Nanoscribe’s printers, it has also become possible to precisely integrate freeform elements into an open or sealed microchannel. Thus, 2PP allows to print nearly any 3D component, such as cell scaffolds, filters and mixers, into prepatterned microchannels, expanding the opportunities in microfluidic applications.

Two-Photon Polymerization for microchannel mastering

The technology of 2PP is also applicable for the fabrication of 2D or 2.5D polymer masters of microchannel systems. This capability further expands the opportunities to miniaturize complex and integrated 2D channel systems as well as to fabricate filigree structures with lateral feature sizes of a few micrometers or even in the submicrometer scale. Nanoscribe’s 2PP technology can be used to pattern a polymer master that includes structures of different scales in one system. The polymer master can then be replicated, e.g. by soft lithography.

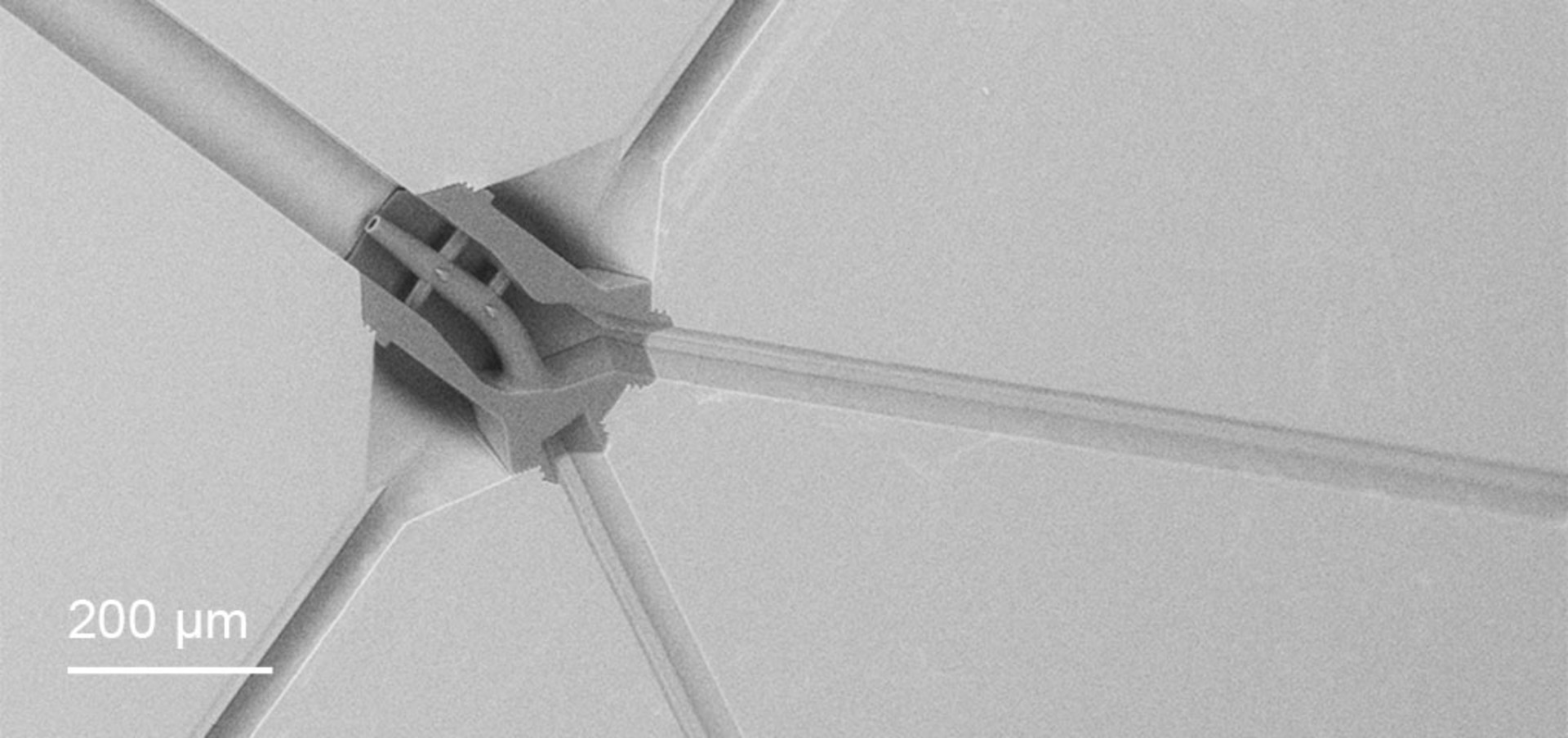

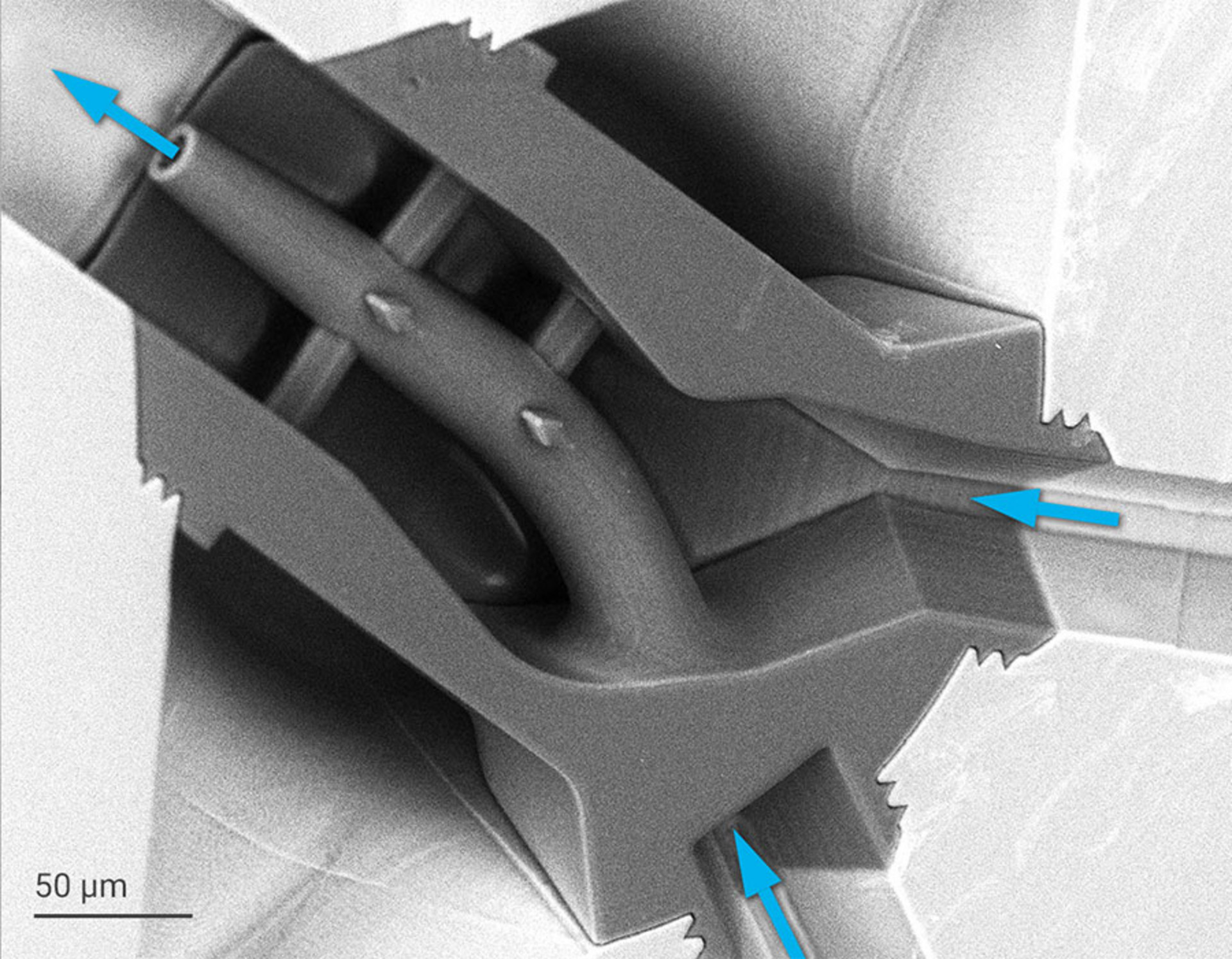

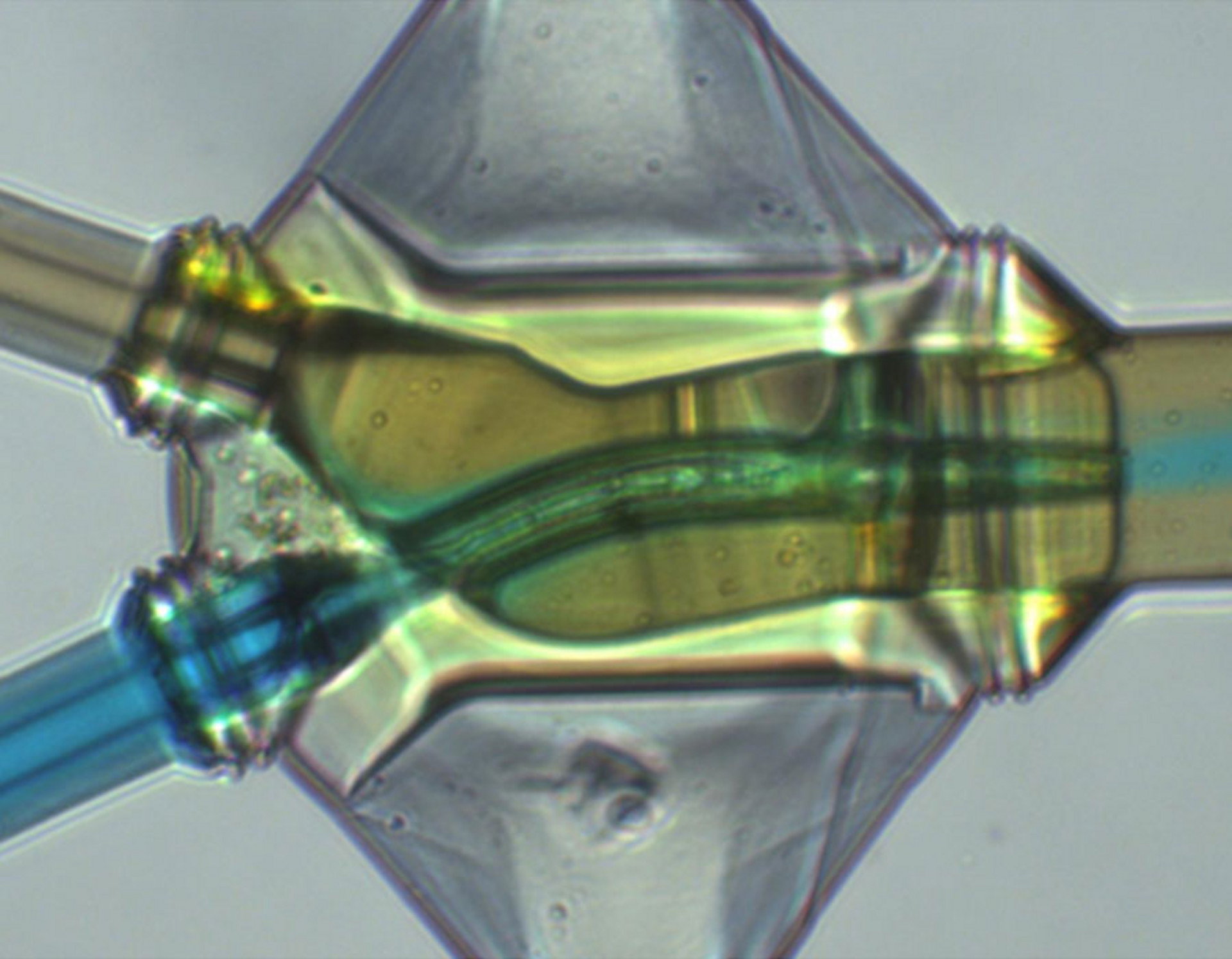

Mastering and in-chip printing of microfluidic devices

To fabricate and miniaturize a wet-spinning process in a microfluidic chip, the scientists combine mastering, replication by soft lithography and in-chip 3D printing. First, a positive master of the 2D microfluidic channel system is printed using 2PP. In a second step, a negative mold of the channel structure is fabricated by casting PDMS over the printed polymer master. This PDMS mold is sealed by adhering it to a microscope slide using oxygen plasma. The channels are then filled with liquid photoresin, followed by an in-chip printing step of the spinneret.